Features

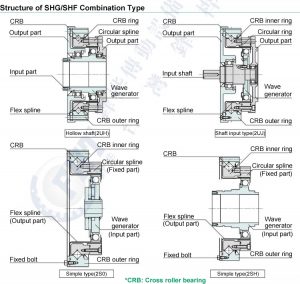

SHG&SHF combination harmonic gearboxes are mainly structured by component sets.The cross roller bearing inside the harmonic drive is with high precision and high rigidity,it is used for holding(main bearing) external loading.

SHG&SHF series harmonic gearbox units are available in nine sizes with gear ratios of 50, 80, 100, 120 and 160:1.These harmonic drive gearboxes are ideal for highly dynamic applications, such as in robot axes. This is supported by: enormous torque density, high-tilt output bearing, lifelong precision and zero backlash.

The integrated output bearing with high tilting capacity enables the direct attachment of heavy payloads without the need for further support, ensuring a simple and space-saving design.

SHG/SHF-2UH harmonic drive is fully sealed with a large hollow shaft diameter to feed through supply lines, shafts or cables for further drive systems.Confirmed by many years of successful service,the gears cover a wide torque range and feature a long service life

SHG/SHF-2SO simple gear units are very compact and lightweight. The absence of input and output flanges make maximum flexibility in design integration. And the gears cover a wide torque range and feature a long service life

SHG/SHF-2SH simply units are very short and lightweight. The absence of input and output flanges make maximum flexibility in design integration. The enlarged hollow shaft can be used to feed through supply lines, shafts or cables for further drive systems. Surly,the gears cover a wide torque range and feature a long service life

Features of SHG&SHF Harmonic Drive Gearbox

*Large diameter, hollow hole and flat shape

*Compact design

*High torque capacity

*High rigidity

*Zero backlash

*Excellent positioning accuracy and rotation accuracy

*Input and output are coaxial

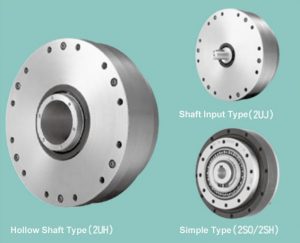

Shape Various Options

SHG&SHF series harmonic gearboxes have 4 kinds of shapes for option.

Please choose the most suitable shape according to the design of mechanical device.

*Large diameter hollow hole structure: hollow type(2UH)

*Correspond to various input forms: shaft input type(2UJ)

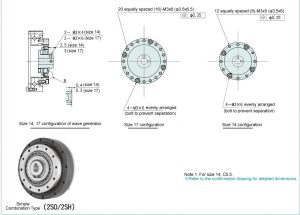

*Easier operation: standard simple type(2S0)

hollow simple type(2SH)

Difference between SHG and SHF Harmonic Drive Gearbox

SHG series harmonic gearbox is used for high torque transmission device,while SHF harmonic gearbox is with standard torque.

*SHG harmonic gearbox torque is 30% higher than that of SHF harmonic gearbox.

*Service time of SHG harmonic gearbox is 43% longer than that of SHF harmonic gearbox.(10000hours)

Structure of SHG&SHF Harmonic Drive Gearboxes

Widely used in robots,metal working machines,communication equipment,crating and packaging machine,paper-making machines,optical machines,printing machine, medical equipment,bending machine,etc.

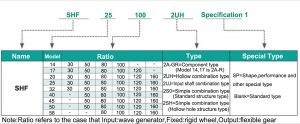

Model Indication

SHF series model indication

SHG series model indication

SHF harmonic gearbox parameters

Parameter

| Model | Ratio | Rated torque of input speed 2000r/min | Max. torque of starting to stop | Max. torque of average load | Instant Max.torque | Max.input speed r/min | Average input speed r/min | ||||||

| Nm | kgfm | Nm | kgfm | Nm | kgfm | Nm | kgfm | Oil lubrication | Grease lubrication | Oil lubrication | Grease lubrication | ||

| 14 | 30 | 4.0 | 0.41 | 9.0 | 0.92 | 6.8 | 0.69 | 17 | 1.7 | 14000 | 8500 | 6500 | 3500 |

| 50 | 5.4 | 0.55 | 18 | 1.8 | 6.9 | 0.7 | 35 | 3.6 | |||||

| 80 | 7.8 | 0.8 | 23 | 2.4 | 11 | 1.1 | 47 | 4.8 | |||||

| 100 | 7.8 | 0.8 | 28 | 2.9 | 11 | 1.1 | 54 | 5.5 | |||||

| 17 | 30 | 8.8 | 0.9 | 16 | 1.6 | 12 | 1.2 | 30 | 3.1 | 10000 | 7300 | 6500 | 3500 |

| 50 | 16 | 1.6 | 34 | 3.5 | 26 | 2.6 | 70 | 7.1 | |||||

| 80 | 22 | 2.2 | 43 | 4.4 | 27 | 2.7 | 87 | 8.9 | |||||

| 100 | 24 | 2.4 | 54 | 5.5 | 39 | 4.0 | 110 | 11 | |||||

| 120 | 24 | 2.4 | 54 | 5.5 | 39 | 4.0 | 86 | 8.8 | |||||

| 20 | 30 | 15 | 1.5 | 27 | 2.8 | 20 | 2.0 | 50 | 5.1 | 10000 | 6500 | 6500 | 3500 |

| 50 | 25 | 2.5 | 56 | 5.7 | 34 | 3.5 | 98 | 10 | |||||

| 80 | 34 | 3.5 | 74 | 7.5 | 47 | 4.8 | 127 | 13 | |||||

| 120 | 40 | 4.1 | 82 | 8.4 | 49 | 5.0 | 147 | 15 | |||||

| 120 | 40 | 4.1 | 87 | 8.9 | 49 | 5.0 | 147 | 15 | |||||

| 160 | 40 | 4.1 | 92 | 9.4 | 49 | 5.0 | 147 | 15 | |||||

| 25 | 30 | 27 | 2.8 | 50 | 5.1 | 38 | 3.9 | 95 | 9.7 | 7500 | 5600 | 5600 | 3500 |

| 50 | 39 | 4.0 | 98 | 10 | 55 | 5.6 | 186 | 19 | |||||

| 80 | 63 | 6.4 | 137 | 14 | 87 | 8.9 | 255 | 26 | |||||

| 100 | 67 | 6.8 | 157 | 16 | 108 | 11 | 284 | 29 | |||||

| 120 | 67 | 6.8 | 167 | 17 | 108 | 11 | 304 | 31 | |||||

| 160 | 67 | 6.8 | 176 | 18 | 108 | 11 | 314 | 32 | |||||

| 32 | 30 | 54 | 5.5 | 100 | 10 | 75 | 7.7 | 200 | 20 | 7000 | 4800 | 4600 | 3500 |

| 50 | 76 | 7.8 | 216 | 22 | 108 | 11 | 382 | 39 | |||||

| 80 | 118 | 12 | 304 | 31 | 167 | 17 | 568 | 58 | |||||

| 100 | 137 | 14 | 333 | 34 | 216 | 22 | 647 | 66 | |||||

| 120 | 137 | 14 | 353 | 36 | 216 | 22 | 686 | 70 | |||||

| 160 | 137 | 14 | 372 | 38 | 216 | 22 | 686 | 70 | |||||

| 40 | 50 | 137 | 14 | 402 | 41 | 196 | 20 | 686 | 70 | 5600 | 4000 | 3600 | 3000 |

| 80 | 206 | 21 | 519 | 53 | 284 | 29 | 980 | 100 | |||||

| 100 | 265 | 27 | 568 | 58 | 372 | 38 | 1080 | 110 | |||||

| 120 | 294 | 30 | 617 | 63 | 451 | 46 | 1180 | 120 | |||||

| 160 | 294 | 30 | 647 | 66 | 451 | 46 | 1180 | 120 | |||||

| 45 | 50 | 176 | 18 | 500 | 51 | 265 | 27 | 950 | 97 | 5000 | 3800 | 3300 | 3000 |

| 80 | 313 | 32 | 706 | 72 | 390 | 40 | 1270 | 130 | |||||

| 100 | 353 | 36 | 755 | 77 | 500 | 51 | 1570 | 160 | |||||

| 120 | 402 | 41 | 823 | 84 | 620 | 63 | 1760 | 180 | |||||

| 160 | 402 | 41 | 882 | 90 | 630 | 64 | 1910 | 195 | |||||

| 50 | 50 | 122 | 12 | 715 | 73 | 175 | 18 | 1430 | 146 | 4500 | 3500 | 3000 | 2500 |

| 80 | 372 | 38 | 941 | 96 | 519 | 53 | 1860 | 190 | |||||

| 100 | 470 | 48 | 980 | 100 | 666 | 68 | 2060 | 210 | |||||

| 120 | 529 | 54 | 1080 | 110 | 813 | 83 | 2060 | 210 | |||||

| 160 | 529 | 54 | 1180 | 120 | 843 | 86 | 2450 | 250 | |||||

| 58 | 50 | 176 | 18 | 1020 | 104 | 260 | 27 | 1960 | 200 | 4000 | 3000 | 2700 | 2200 |

| 80 | 549 | 56 | 1480 | 151 | 770 | 79 | 2450 | 250 | |||||

| 100 | 696 | 71 | 1590 | 162 | 1060 | 108 | 3180 | 325 | |||||

| 120 | 745 | 76 | 1720 | 176 | 1190 | 121 | 3330 | 340 | |||||

| 160 | 745 | 76 | 1840 | 188 | 1210 | 123 | 3430 | 350 | |||||

| Note:Moment of inertia I=1/4GD² | |||||||||||||

Note:Moment of inertia I=1/4GD²

SHG harmonic gearbox parameters

| Model | Ratio | Rated torque of input speed 2000r/min | Max. torque of starting to stop | Max. torque of average load | Instant Max.torque | Max.input speed r/min | Average input speed r/min | ||||||

| Nm | kgfm | Nm | kgfm | Nm | kgfm | Nm | kgfm | Oil lubrication | Grease lubrication | Oil lubrication | Grease lubrication | ||

| 14 | 50 | 7.0 | 0.7 | 23 | 2.3 | 9 | 0.9 | 46 | 4.7 | 14000 | 8500 | 6500 | 3500 |

| 80 | 10 | 1.0 | 30 | 3.1 | 14 | 1.4 | 61 | 6.2 | |||||

| 100 | 10 | 1.0 | 36 | 3.7 | 14 | 1.4 | 70 | 7.2 | |||||

| 17 | 50 | 21 | 2.1 | 44 | 4.5 | 34 | 3.4 | 91 | 9 | 10000 | 7300 | 6500 | 3500 |

| 80 | 29 | 2.9 | 56 | 5.7 | 35 | 3.6 | 113 | 12 | |||||

| 100 | 31 | 3.2 | 70 | 7.2 | 51 | 5.2 | 143 | 15 | |||||

| 120 | 31 | 3.2 | 70 | 7.2 | 51 | 5.2 | 112 | 11 | |||||

| 20 | 50 | 33 | 3.3 | 73 | 7.4 | 44 | 4.5 | 127 | 13 | 10000 | 6500 | 6500 | 3500 |

| 80 | 44 | 4.5 | 96 | 9.8 | 61 | 6.2 | 165 | 17 | |||||

| 100 | 52 | 5.3 | 107 | 10.9 | 64 | 6.5 | 191 | 20 | |||||

| 120 | 52 | 5.3 | 113 | 11.5 | 64 | 6.5 | 191 | 20 | |||||

| 160 | 52 | 5.3 | 120 | 12.2 | 64 | 6.5 | 242 | 20 | |||||

| 25 | 50 | 51 | 5.2 | 127 | 13 | 72 | 7.3 | 332 | 25 | 7500 | 5600 | 5600 | 3500 |

| 80 | 82 | 8.4 | 178 | 18 | 113 | 12 | 369 | 34 | |||||

| 100 | 87 | 8.9 | 204 | 21 | 140 | 14 | 395 | 38 | |||||

| 120 | 87 | 8.9 | 217 | 22 | 140 | 14 | 408 | 40 | |||||

| 160 | 87 | 8.9 | 229 | 23 | 140 | 14 | 497 | 42 | |||||

| 32 | 50 | 99 | 10 | 281 | 29 | 140 | 14 | 738 | 51 | 7000 | 4800 | 4600 | 3500 |

| 80 | 153 | 16 | 395 | 40 | 217 | 22 | 841 | 75 | |||||

| 100 | 178 | 18 | 433 | 44 | 281 | 29 | 892 | 86 | |||||

| 120 | 178 | 18 | 459 | 47 | 281 | 29 | 892 | 91 | |||||

| 160 | 178 | 18 | 484 | 49 | 281 | 29 | 892 | 91 | |||||

| 40 | 50 | 178 | 18 | 523 | 53 | 255 | 26 | 892 | 91 | 5600 | 4000 | 3600 | 3000 |

| 80 | 268 | 27 | 675 | 69 | 369 | 38 | 1270 | 130 | |||||

| 100 | 345 | 35 | 738 | 75 | 484 | 49 | 1400 | 143 | |||||

| 120 | 382 | 39 | 802 | 82 | 586 | 60 | 1530 | 156 | |||||

| 160 | 382 | 39 | 841 | 86 | 586 | 60 | 1530 | 156 | |||||

| 45 | 50 | 229 | 23 | 650 | 66 | 345 | 35 | 1235 | 126 | 5000 | 3800 | 3300 | 3000 |

| 80 | 407 | 41 | 918 | 94 | 507 | 52 | 1651 | 168 | |||||

| 100 | 459 | 47 | 982 | 100 | 650 | 66 | 2041 | 208 | |||||

| 120 | 523 | 53 | 1070 | 109 | 806 | 82 | 2288 | 233 | |||||

| 160 | 523 | 53 | 1147 | 117 | 819 | 84 | 2483 | 253 | |||||

| 50 | 80 | 484 | 49 | 1223 | 125 | 675 | 69 | 2418 | 247 | 4500 | 3500 | 3000 | 2500 |

| 100 | 611 | 62 | 1274 | 130 | 866 | 88 | 2678 | 273 | |||||

| 120 | 688 | 70 | 1404 | 143 | 1057 | 108 | 2678 | 273 | |||||

| 160 | 688 | 70 | 1534 | 156 | 1096 | 112 | 3185 | 325 | |||||

| 58 | 80 | 714 | 73 | 1924 | 196 | 1001 | 102 | 3185 | 325 | 4000 | 3000 | 2700 | 2200 |

| 100 | 905 | 92 | 2067 | 211 | 1378 | 141 | 4134 | 422 | |||||

| 120 | 969 | 99 | 2236 | 228 | 1547 | 158 | 4329 | 441 | |||||

| 160 | 969 | 99 | 2392 | 244 | 1573 | 160 | 4459 | 455 | |||||

| 65 | 80 | 969 | 99 | 2743 | 280 | 1352 | 138 | 4836 | 493 | 3500 | 2800 | 2400 | 1900 |

| 100 | 1236 | 126 | 2990 | 305 | 1976 | 202 | 6175 | 630 | |||||

| 120 | 1236 | 126 | 3263 | 333 | 2041 | 208 | 6175 | 630 | |||||

| 160 | 1236 | 126 | 3419 | 349 | 2041 | 208 | 6175 | 630 | |||||

| Note:Moment of inertia I=1/4GD² | |||||||||||||

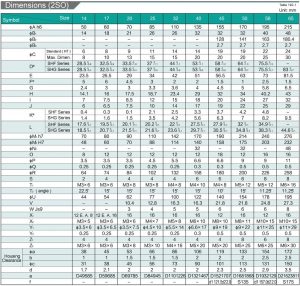

Dimensions

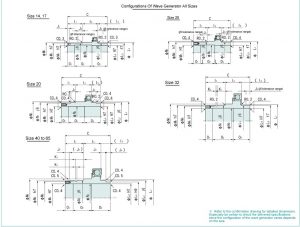

Dimensions of SHG&SHF Harmonic Gearboxes

2UH Type Dimensions

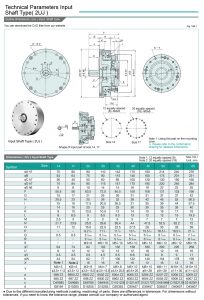

2UJ Type Dimensions

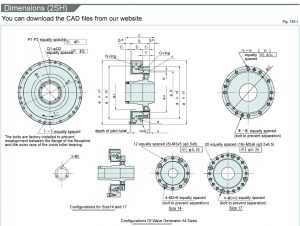

2SH Type Dimensions

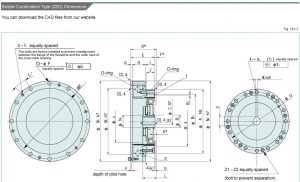

2SO Type Dimensions

Weight

| Hollow combination type (2UH) weight | ||||||||||

| Model | 14 | 17 | 20 | 25 | 32 | 40 | 45 | 50 | 58 | 65 |

| weight(kg) | 0.71 | 1 | 1.38 | 2.1 | 4.5 | 7.7 | 10 | 14.5 | 20 | 28.5 |

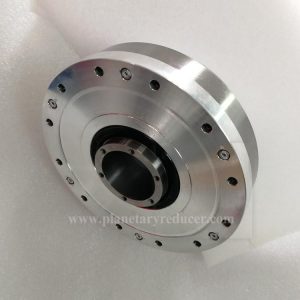

| Simple combination type(2SO) weight | ||||||||||

| Model | 14 | 17 | 20 | 25 | 32 | 40 | 45 | 50 | 58 | 65 |

| weight(kg) | 0.41 | 0.57 | 0.81 | 1.31 | 2.94 | 5.1 | 6.5 | 9.6 | 13.5 | 19.5 |

| Simple combination type(2SH) weight | ||||||||||

| Model | 14 | 17 | 20 | 25 | 32 | 40 | 45 | 50 | 58 | 65 |

| weight(kg) | 0.45 | 0.63 | 0.89 | 1.44 | 3.1 | 5.4 | 6.9 | 10.2 | 14.1 | 20.9 |

| Input shaft combination type(2UJ)weight | ||||||||||

| Model | 14 | 17 | 20 | 25 | 32 | 40 | 45 | 50 | 58 | 65 |

| weight(kg) | 0.66 | 0.94 | 1.38 | 2.1 | 4.4 | 7.3 | 9.8 | 13.9 | 19.4 | 26.5 |

Download

Real Pictures

Combination Type(2UH)

Silver color unit is with high quality and high rigidity, used for high torque occasion, ideal option for robot application.

Black color unit is the economical type

Simple Combination Type(2SH)

Shaft Input Type