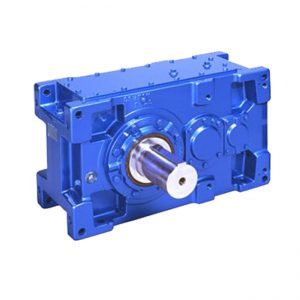

Features

1.HB series standard industrial gearbox use general design scheme, it can became the industry-specific gearbox as per customer request.

2.Commonly used box for Parallel shaft, rectangular shaft, vertical, horizontal shaft. Spare parts kinds reduce, models increase.

3.Sound absorption box structure, larger box surface and large fan, cylinder gear and spiral bevel gear are both use advanced technology of gear grinding to reduce the noise and temperature rise, running reliability can be increased, transmitted power increase.

4.Flange or shaft input

5.Output: Solid shaft with flat key, Hollow shaft with flat key,solid shaft with connection of heave tight plate, hollow shaft or solid shaft with connection of spline, solid shaft with connection of flange.

6.Installation methods: Vertical, horizontal, swing base,torsion arm

7.Ratio 1.25-450. Can combine with R, K,S series reducer to get much more larger ratio.

Model selection

1.Calculate your required ratio: input speed/output speed

2.Confirm the rated power of reducer ( see the parameter sheet)

3.Check the max. Torque, peak working torque, starting torque or braking torque should meet the requirement: reducer rated power≥(Max. Torque of input shaftxinput speed)/9550 x peak torque coefficient.

4.Check if the output shaft allow additional load.

5.Check if the practical ratio can meet your

6.Ensure oil supply ways:

Horizontal mounting reducer lubricating: immersion oil splashing

Vertical mounting reducer lubricating: immersion oil or forced lubrication

Customized forced lubrication methods can be offered.

7.Check the heat balance power

About the details, please refer to our HB model selection instruction file.

Details:

1.Reducer Case: High quality cast iron case

2.Gears: Hardened face gear adopt superior quality alloy steel, the surface with carburizing and quenching treatment, gear grinding , elaborate process. ( gear surface hardness is HRC60 after grinding, hardened layer thickness>0.5mm) Gear surface grinding precision reach to 5-6 level

3.Flat key: steel material

4.Bearing: Use domestic famous bearing or imported bearing

5.Oil seal: Taiwan framework oil seal

Application

HB series reducers are widely used in various conveyor lines, production lines and machinery fields like petroleum, chemical, light industry, textile, food, plastic,pharmacy, ceramics, printing&dyeing, metallurgy, mining,tabacco,paper making, tanning, woodworking, electronics instrument, glass, environmental protection.

FAQ

1.Lead time: Normally 10-15 days after confirm your deposit.

2.MOQ is 1 PC

3.Warranty: 1 year

4.Gear reducer can be customized?

Yes, please advise your technical requirement..

5.Where is the gear reducer manufactured?

Produced in China Mainland.

6.Your gear reducer was ever shipped to which countries?

Our gear reducer has been sold to various countries like Russia, Vietnam, Canada, Australia, UAE, Japan etc..

Installation

1.Please make the central axis centered when install the gear motor, the error shouldn’t be greater than use compensation value of coupler. Good centering can extend the service life and realize a ideal transmission efficiency.

2.Hummer knocking is forbidden when mounting driving medium on the output shaft. Generally we make use of assemble fixture and inner thread of shaft, bolt to press driving medium, otherwise the inner parts of gear motor may be damaged.

3.Gear reducer should be tightly mounted on stable horizontal base, make sure the oil can be exhausted from oil drain tank and the cold air can circulate fluently. Because vibration and noise will be caused by unreliable base during running, the bearing and gears also will be damaged. When driving medium has outthrust or use gear, chain wheel to drive, please add a protective device.

4.As per the prescribed mounting unit, guarantee the workers can close to oil pointer, breather plug and oil drain plug more conveniently. After move gear reducer to its place, inspect comprehensively the compaction reliability of each fasteners. Gear reducer is lubricated by oil grease, please replace the screw plug with breather plug before operation.

Note: After a certain time running of the gear motor, please regularly check the gearbox oil level to avoid the probable leakage caused by motor shell. If the working temperature is too low or too high, you can change the lubricant oil number.

Maintenance:

1.During operation, if the oil temperature rise is over than 80 degree or the oil pool temperature exceed 100 degree or there is abnormal noise, please stop using and inspect the reason to do troubleshooting. Continue to use the reducer after exchange lubricate oil.

2.If the ambient temperature is below -10 degree, please consider its influence to reducer when select model. A heater can be equipped with the reducer, this is very important to reducer’s lubrication maintenance. Regularly inspect the oil level, check if there is any abnormal situation for noise, vibration.

3.Reducer can play its role at high limit by correct maintaining.

1)replace the oil after first usage of 300hrs, after this, change the oil every 2500 hrs usage.

2)During the usage, inspect the oil quality regularly, please change oil if there is situation of impurity,aging, degenerative.

How to store the reducer?

1)Keep the reducer in a clean and dry place.

2)If it will be stored outdoor or in a humid place, please put the reducer in a box and packed tightly with plastic bag to avoid the rain and external erosion. ( take measure of anti-condensation and anti-rust)

4. Cautions during operation:

1)Overload is forbidden.

2)Input speed can not exceed the proper max. Speed.

3)Please stop and check the gearbox if there are the following occurs:

Temperature rise suddenly

Abnormal big noise in a sudden

Speed became unstable suddenly

5.Warranty instruction:

The following cost and damages are not included in our warranty:

1)Freight cost

2)If the Reducer connect with or insert in a unit, when we dismounting or mounting on the unit and other extra action, there will be a cost.( this is not contained in the warranty)

3)The indirect damage that user lost the appliance chance or business break off due to reducer breakdown.

4)Other derivative and accompanying damages.