Features

PAF series speed reducers are one of our earliest products.PAF planetary gearboxes are

with compact body,suits for any installation of motion control systems.FHT PAF planetary

precision gearbox has a full dimensions for option,it can match any of servo motors and

stepper motors.PAF planetary gear box is an economical type product,it not only have low

Price,but also have good quality of low noise and low backlash,it is the ideal option for

limited budget and high precision requirements.

PAF series planetary speed reducer is with round body design for economic transmission application.

(1)Integrated design of planet carrier and output shaft ensures the maximum torque stiffness and stability.

(2)Electroless Nlickel deposition treatment and black anodizing treating are employed to gear box surface and motar adapter module respectively the tolerance to the environment and resistant to corrosion are enhanced

(3)Low backlash

(4)High efficiency(95%)

(5)Life time lubrication

Guidelines

How to choose a correct PAF model?

(1)Check your motor drawing,offer the below dimensions:

φS:shaft diameter

LB:motor convex circle diameter

φLA:motor flange PCD

LS:shaft length

LE:motor convex circle thickness

φLZ:motor mounting hole size

Then compare these dimensions to our gearbox dimensions(refer to our catalogue)you can probably know the frame size of our gearbox.

(2)What’s the ratio or output speed you need?Check if the gearbox output torque>motor torque*ratio

Ratio i=Input speed(RPM)/gearbox output speed(RPM)

Motor torque(N.m)=9550*motor power(KW)/motor speed(RPM)

(3)Make sure the precision(backlash)you need,then you can know which type of gearbox you need.

(4)If you don’t have the information above,please just tell us the motor brand and type,output speed or output torque you need,then we are pleasure to help you choose a suitable model.

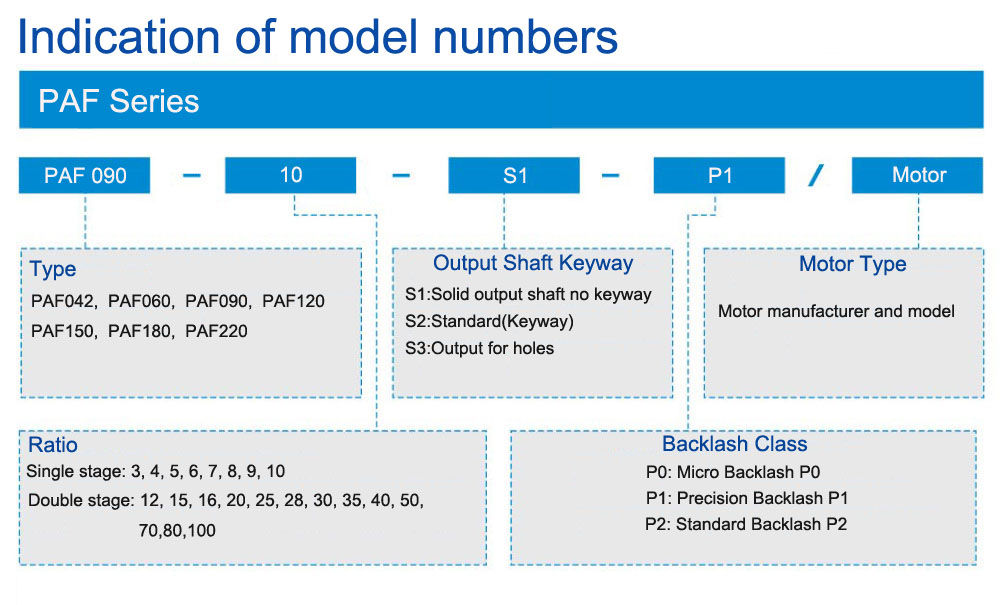

Indication

Parameters

| Model No. | Unit | Stage | Ratio | PAF042 | PAF060 | PAF090 | PAF120 | PAF150 | PAF180 | PAF220 |

| Rated Output Torque | Nm | 1 | 3 | 15 | 46 | 145 | 280 | 520 | 1020 | 1550 |

| 4 | 17 | 48 | 155 | 300 | 550 | 1280 | 2160 | |||

| 5 | 17 | 48 | 158 | 310 | 530 | 1250 | 2100 | |||

| 6 | 12 | 42 | 120 | 240 | 410 | 980 | 1350 | |||

| 7 | 13 | 47 | 143 | 290 | 500 | 1030 | 1580 | |||

| 8 | 12 | 39 | 108 | 230 | 420 | 880 | 1260 | |||

| 9 | 10 | 38 | 100 | 220 | 410 | 880 | 1450 | |||

| 10 | 12 | 42 | 120 | 260 | 475 | 950 | 1530 | |||

| 2 | 12 | 15 | 48 | 155 | 300 | 530 | 1100 | 1750 | ||

| 15 | 15 | 48 | 150 | 280 | 520 | 1050 | 1650 | |||

| 16 | 17 | 47 | 158 | 300 | 530 | 1200 | 2050 | |||

| 20 | 17 | 48 | 155 | 300 | 530 | 1200 | 2050 | |||

| 25 | 17 | 47 | 158 | 310 | 520 | 1200 | 2000 | |||

| 28 | 16 | 46 | 150 | 300 | 520 | 1100 | 1850 | |||

| 30 | 15 | 46 | 145 | 280 | 500 | 1050 | 1600 | |||

| 35 | 16 | 46 | 155 | 290 | 500 | 1020 | 1500 | |||

| 40 | 17 | 46 | 150 | 290 | 410 | 1100 | 1350 | |||

| 50 | 15 | 45 | 145 | 290 | 490 | 1000 | 1300 | |||

| 70 | 13 | 45 | 140 | 280 | 490 | 1000 | 1200 | |||

| 80 | 10 | 38 | 110 | 230 | 410 | 960 | 980 | |||

| 100 | 10 | 39 | 120 | 260 | 450 | 950 | 1100 | |||

| Max. Output Torque | Nm | 1,2 | 3-100 | 3 Times of Normal Output Torque | ||||||

| Rated Input Speed | Rpm | 1,2 | 3-100 | 3000 | 3000 | 3000 | 3000 | 2500 | 2000 | 2000 |

| Max. Input Speed | Rpm | 1,2 | 3-100 | 6000 | 6000 | 6000 | 5500 | 4500 | 4500 | 4000 |

| Precision Backlash P1 | Arcmin | 1 | 3-10 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 |

| 2 | 12-100 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ||

| Standard Backlash P2 | Arcmin | 1 | 3-10 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 |

| 2 | 12-100 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ||

| Torsional Rigidity | Nm/arcmin | 1,2 | 3-100 | 3 | 7 | 12 | 25 | 50 | 140 | 210 |

| Max. Radial Force | N | 1,2 | 3-100 | 750 | 1130 | 3000 | 6700 | 9150 | 14500 | 48500 |

| Max. Axial Force | N | 1,2 | 3-100 | 310 | 600 | 1500 | 3220 | 4550 | 7100 | 24000 |

| Service Life | Hr | 1,2 | 3-100 | 20000hrs | ||||||

| Efficiency | % | 1 | 3-10 | ≥97% | ||||||

| 2 | 12-100 | ≥94% | ||||||||

| Weight | Kg | 1 | 3-10 | 0.5 | 1.1 | 2.9 | 7.8 | 15 | 28 | 52 |

| 2 | 12-100 | 0.8 | 1.39 | 3.9 | 9.6 | 18.9 | 35 | 66 | ||

| Operating Temperature | ℃ | 1,2 | 3-100 | (-15℃~+90℃) | ||||||

| Lubrication | 1,2 | 3-100 | Synthetic Grease | |||||||

| Protection Class | 1,2 | 3-100 | IP65 | |||||||

| Mounting Position | 1,2 | 3-100 | Any Direction | |||||||

| Noise Level | dB(A) | 1,2 | 3-100 | ≤63 | ≤63 | ≤63 | ≤65 | ≤65 | ≤67 | ≤70 |

Moment of Inertia

| Model No. | Unit | Stage | Ratio | PAF042 | PAF060 | PAF090 | PAF120 | PAF150 | PAF180 | PAF220 |

| Moment of Inertia | kg.cm2 | 1 | 3 | 0.03 | 0.16 | 0.61 | 3.25 | 9.21 | 28.98 | 69.61 |

| 4 | 0.03 | 0.14 | 0.48 | 2.74 | 7.54 | 23.67 | 54.37 | |||

| 5 | 0.03 | 0.13 | 0.47 | 2.71 | 7.42 | 23.29 | 53.27 | |||

| 6 | 0.03 | 0.13 | 0.45 | 2.65 | 7.25 | 22.75 | 51.72 | |||

| 7 | 0.03 | 0.13 | 0.45 | 2.62 | 7.14 | 22.48 | 50.97 | |||

| 8 | 0.03 | 0.13 | 0.44 | 2.58 | 7.07 | 22.59 | 50.84 | |||

| 9 | 0.03 | 0.13 | 0.44 | 2.57 | 7.04 | 22.53 | 50.63 | |||

| 10 | 0.03 | 0.13 | 0.44 | 2.57 | 7.03 | 22.51 | 50.56 | |||

| 2 | 12-40 | 0.03 | 0.03 | 0.13 | 0.47 | 2.71 | 7.42 | 23.29 | ||

| 50-100 | 0.03 | 0.03 | 0.13 | 0.44 | 2.57 | 7.03 | 22.51 |

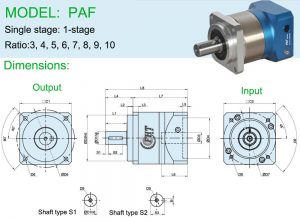

Reducer Dimensions:

(1) Single stage(Ratio:3, 4, 5, 6,7, 8,9,10)

Unit:mm

| Size | PAF042-L1 | PAF060-L1 | PAF090-L1 | PAF120-L1 | PAF150-L1 | PAF180-L1 | PAF220-L1 |

| D1 | 13 | 16 | 22 | 32 | 40 | 55 | 75 |

| D2 | 35 | 50 | 80 | 110 | 130 | 160 | 180 |

| D3 | 8(≤11) | 14(≤14) | 19(≤24) | 24(≤32) | 35(≤42) | 38(≤50) | 55(≤55) |

| D4 | 30(30-50) | 50(30-70) | 70(50-110) | 110(50-130) | 130(95-180) | 180(95-180) | 200(180-250) |

| D5 | 50 | 70 | 100 | 130 | 165 | 215 | 250 |

| D6 | 4-Φ4.2 | 4-Φ5.5 | 4-Φ7 | 4-Φ9 | 4-Φ11 | 4-Φ13 | 4-Φ17 |

| D7 | 46(22-70) | 70(45-90) | 90(70-145) | 145(70-145) | 145(90-215) | 200(145-300) | 235(200-300) |

| D8 | M3-M5 | M3-M6 | M4-M10 | M6-M10 | M8-M12 | M10-M12 | M10-M12 |

| D9 | M4X0.7P | M5X0.8P | M6X1.0P | M8X1.25P | M12X1.75P | M12X1.75P | M20X2.5P |

| L1 | 20 | 28 | 36 | 50 | 74 | 82 | 105 |

| L2 | 5.5 | 7 | 10 | 12 | 15 | 20 | 30 |

| L3 | 7 | 8 | 9 | 12 | 15 | 16 | 20 |

| L4 | 27 | 36 | 47.5 | 65 | 92 | 106 | 138 |

| L5 | 4(2-7) | 5(2-10) | 8(4-10) | 10(4-10) | 10(4-10) | 12.5(4-12.5) | 12.5(4-12.5) |

| L6 | 26 | 32(30-42) | 45(25-60) | 65(50-80) | 84(50-90) | 105(50-130) | 105(60-130) |

| L7 | 56 | 79 | 94.5 | 126.8 | 155.8 | 177 | 279 |

| L8 | 83 | 115 | 142 | 191.8 | 247.8 | 283 | 417 |

| C1 | 42 | 62 | 90 | 120 | 150 | 180 | 220 |

| C2 | 42(42-70) | 62(62-90) | 90(90-165) | 120(115-160) | 150(142-200) | 182(182-220) | 220 |

| S1 | 3 | 3 | 5 | 5 | 5 | 6 | 7 |

| S2 | 15 | 20 | 25 | 40 | 60 | 70 | 90 |

| S3 | 15 | 18 | 24.5 | 35 | 43 | 59 | 79.5 |

| B | 5 | 5 | 6 | 10 | 12 | 16 | 20 |

Note 1:Inside of ()is the optional range of sizes,outside of ()is the standard sizes.

Note 2:The reducer output shaft size and length can be customized for customers.

Note 3:Input sizes can be subject to changed according to kinds of servo motor or stepper motor size.

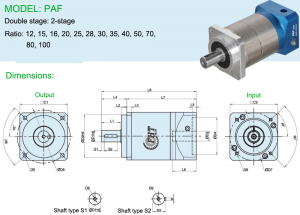

(2) Double stage(Ratio: 12,15,16,20,25,28,30,35,40,50,70,80,100)

unit:mm

| Size | PAF042-L2 | PAF060-L2 | PAF090-L2 | PAF120-L2 | PAF150-L2 | PAF180-L2 | PAF220-L2 |

| D1 | 13 | 16 | 22 | 32 | 40 | 55 | 75 |

| D2 | 35 | 50 | 80 | 110 | 130 | 160 | 180 |

| D3 | 8(≤11) | 14(≤14) | 19(≤24) | 24(≤32) | 35(≤42) | 38(≤50) | 55(≤55) |

| D4 | 30(30-50) | 50(30-70) | 70(50-110) | 110(50-130) | 130(95-180) | 180(95-180) | 200(180-250) |

| D5 | 50 | 70 | 100 | 130 | 165 | 215 | 250 |

| D6 | 4-Φ4.2 | 4-Φ5.5 | 4-Φ7 | 4-Φ9 | 4-Φ11 | 4-Φ13 | 4-Φ17 |

| D7 | 46(22-70) | 70(45-90) | 90(70-145) | 145(70-145) | 145(90-215) | 200(145-300) | 235(200-300) |

| D8 | M3-M5 | M3-M6 | M4-M10 | M6-M10 | M8-M12 | M10-M12 | M10-M12 |

| D9 | M4X0.7P | M5X0.8P | M6X1.0P | M8X1.25P | M12X1.75P | M12X1.75P | M20X2.5P |

| L1 | 20 | 28 | 36 | 50 | 74 | 82 | 105 |

| L2 | 5.5 | 7 | 10 | 12 | 15 | 20 | 30 |

| L3 | 7 | 8 | 9 | 12 | 15 | 16 | 20 |

| L4 | 27 | 36 | 47.5 | 65 | 92 | 106 | 138 |

| L5 | 4(2-7) | 5(2-10) | 8(4-10) | 10(4-10) | 10(4-10) | 12.5(4-12.5) | 12.5(4-12.5) |

| L6 | 26 | 32(30-42) | 45(25-60) | 65(50-80) | 84(50-90) | 105(50-130) | 105(60-130) |

| L7 | 72 | 111.5 | 131.0 | 175.3 | 213.3 | 257 | 328 |

| L8 | 99 | 147.5 | 178.5 | 240.3 | 305.3 | 363 | 466 |

| C1 | 42 | 62 | 90 | 120 | 150 | 180 | 220 |

| C2 | 42(42-70) | 62(62-90) | 90(90-165) | 120(115-160) | 150(142-200) | 182(182-220) | 220 |

| S1 | 3 | 3 | 5 | 5 | 5 | 6 | 7 |

| S2 | 15 | 20 | 25 | 40 | 60 | 70 | 90 |

| S3 | 15 | 18 | 24.5 | 35 | 43 | 59 | 79.5 |

| B | 5 | 5 | 6 | 10 | 12 | 16 | 20 |

Note 1:Inside of ()is the optional range of sizes,outside of ()is the standard sizes.

Note 2:The reducer output shaft size and length can be customized for customers.

Note 3:Input sizes can be subject to changed according to kinds of servo motor or stepper motor size.

Characteristics

(1)Gears:the gear material is made of high quality alloy steel, and the optimum hardness is achieved through the carburizing treatment of carbon and nitrogen. Through machine tool processing, obtained high precision, high wear resistance and high impact toughness.The gears adopt special grease lubrication and IP65 protection grade seal design, the output shaft surface polishing treatment, and adopt reasonable tolerance. Ensure minimum friction, count and reduce startup load. No oil leakage or maintenance in service life in any direction.

(2)Output planet rack: the planetary arm frame and the output shaft adopt a one-piece structure, and the planetary wheel is supported on both ends to ensure maximum torque output. The three holes of planetary frame adopt German imported machine tool to make sure the center distance of reducer is the minimum.

(3)Output inner ring: the tooth ring and the output side shell adopts the integral design, adopt the high quality steel, through hot forging forming, thus obtain the higher material density. The integrated design ensures that all geometric dimensions are processed at one time, with higher precision and strength than other embedded and clamped structures.

(4)Input shaft:input shaft and the locking device adopts integrated design, double bolt symmetric distribution, to achieve the dynamic balance at the same time, through double bolt strong lock, effectively prevent motor shaft driving sliding, achieve high accuracy zero back power transmission.

(5)Install flange:advanced connecting plate design, easy to install with various factory brand servo, stepping motor perfectly.

Application

PAF series planetary reducers are widely used in Printer, Belt Conveyer, Gantry Robot, Auto packing sealing machine, Packing machine ( vertical pillow), Packing machine ( horizontal pillow), Dispenser Robot, Loader robot etc.

Installation

(1)How to install the gearbox?

Step 1: Wipe off the anti-rust agent and grease on the motor shaft;

Step 2: Remove the rubber plug;

Step 3: Turn the input shaft until the cap screw is seen. Make sure the cap screw is loosened.

Step 4: Please place reducer vertically on a flat surface to make the surface of motor mounting upwards. Carefully insert motor shaft into the input shaft.( it should be inserted smoothly) Make sure the motor flange is perfectly fit to the reducer’s flange. Tighten the motor mounting bolt as per appointed fastening torque.

Step 5: Tightening the clamping bolt of input shaft with wrench according to the proper torque.

Step 6: Re-install the rubber plug. Finish the installation.

(2)How to store the reducer?

1) Keep the reducer in a clean and dry place.

2) If it will be stored outdoor or in a humid place, please put the reducer in a box and packed tightly with plastic bag to avoid the rain and external erosion. ( take measure of anti-condensation and anti-rust)

(3)Cautions for operation:

1) Please confirm the reducer model number confirm to the one you ordered when the reducer reach to you.

2) There is anti-rust agent on the reducer input and output shaft, please clean it before using.

3) Remove the rubber plug, wipe off the anti-rust agent.

4) The reducer was already filled with lubrication oil. You can use it right now.

5) When initial operation, please confirm the rotate direction of the output shaft, then increase the load little by little.

(4)Cautions during operation:

1) Overload is forbidden.

2) Input speed can not exceed the proper max. Speed.

3) Please stop and check the reducer if there are the following occurs:

Temperature rise suddenly

Abnormal big noise in a sudden

Speed became unstable suddenly

(5)Warranty instruction:

The following cost and damages are not included in our warranty:

1) Freight cost

2) If the Reducer connect with or insert in a unit, when we dismounting or mounting on the unit and other extra action, there will be a cost.( this is not contained in the warranty)

3) The indirect damage that user lost the appliance chance or business break off due to reducer breakdown.

4) Other derivative and accompanying damages.

Download

FAQ

1. What’s your delivery time?

Lead time: Normally 15-25 days after confirm your deposit. Products in stock will be delivered 3-5 days after your deposit.

2. What’s your MOQ?

MOQ is 1 PC

3. How long is your warranty?

Warranty: 1 year

4. Planetary gearbox can be customized?

Yes, please send your servo motor dimensions drawing.

5. Where is the gearbox manufactured?

Produced in Taiwan.

6. Your gearbox was ever shipped to which countries?

Our gearbox has been sold to various countries like Russia, Vietnam, Canada, Australia, UAE, Japan etc..

7. You are a factory or trading company?

We are factory, the manufacturer.