Features

PAW-2C-K is a double hollow shaft clamping spiral bevel gearbox with keyway.Such right angle planetary gearbox is suitable for the application that require axis to go through the hollow shaft.The clamping and keyway design can effectively prevent shaft transmission from slipping when in the large load motion control.

PAW-2C-K right angle 90 degree gearbox is attached with input flange offering an easy mount with motor.The spiral bevel gear and spur gear planetary unit feature the 90 degree servo gearbox a compact structure.The integrated stainless steel body and optimized design ensures PAW-2C-K right angle gearbox with high precision,high torque and high rigidity ,therefore,rotating smoothly with low noise and generate low heat.

PAW-2C-K right angle gearbox have a broad range of ratio for option:

1-stage:3, 4 ,5, 6, 7, 10

2-stage:12, 15, 16, 20, 25, 28, 30, 35, 40, 50, 60, 70, 100

The 90 degree gearbox nominal torque is 10Nm~1200Nm,suitable for different loads of the motion control.

PAW-2C-K 90 degree right angle gearbox have three types of backlash:

Standard backlash: 10~15arcmin

Precision backlash(B2):5~8arcmin

Precision backlash(B1):3~5arcmin

Sizes available: PAW070A / PAW085A / PAW105A / PAW125A / PAW125B / PAW150A / PAW150B / PAW180A / PAW180B

Widely used in Printer, Belt Conveyors, Gantry Robot, Auto packing sealing machine, Packing machine (vertical pillow), Packing machine (horizontal pillow), Dispenser Robot, Loader robot and some other heavy load case.

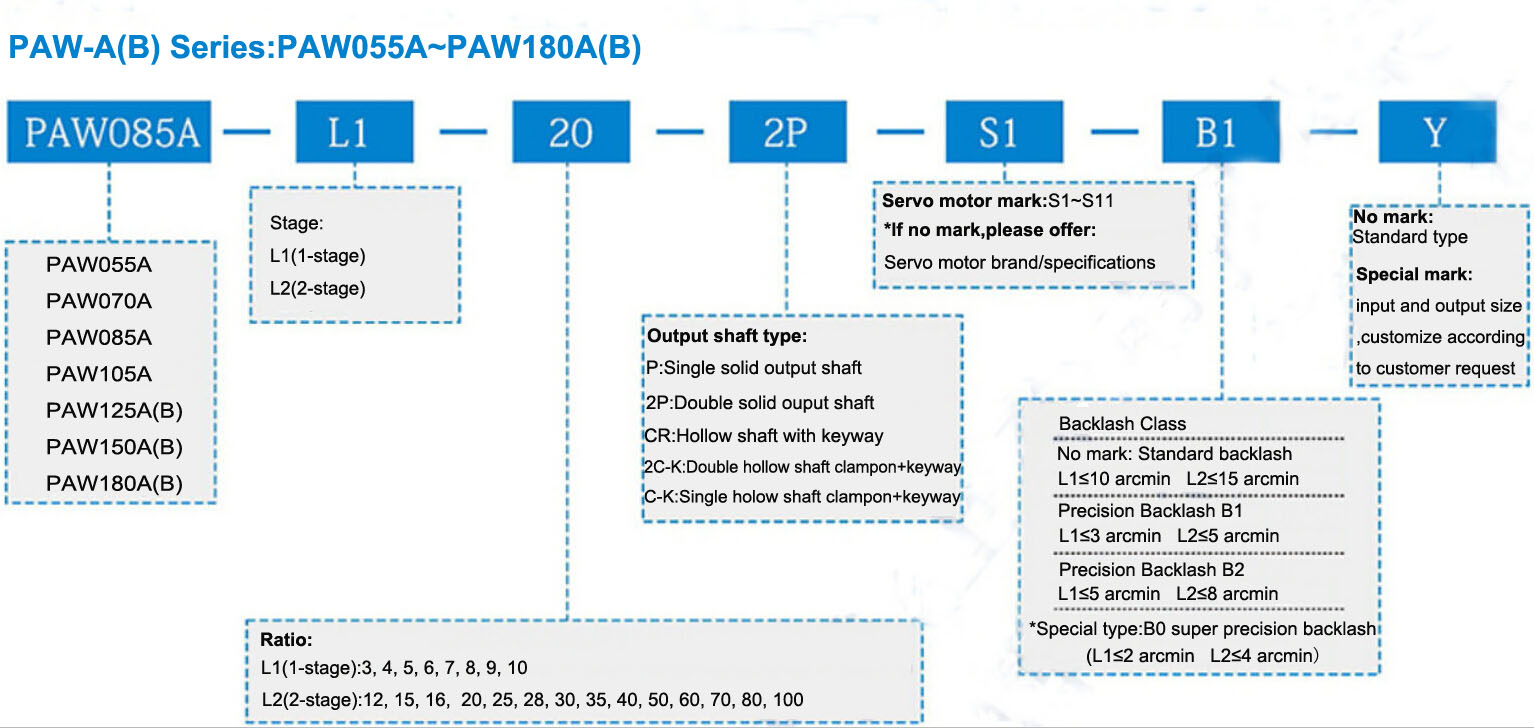

Model indication

Parameters

| Model No. | Unit | Stage | Ratio(i) | PAW055A | PAW070A | PAW085A | PAW105A | PAW125A | PAW125B | PAW150A | PAW150B | PAW180A | PAW180B |

| Rated OutputTorque | Nm | L1 | 1/3 | 10 | 30 | 40 | 100 | 230 | 100 | 400 | 230 | 900 | 450 |

| 1/4 | 15 | 30 | 50 | 150 | 250 | 160 | 500 | 330 | 1100 | 550 | |||

| 1/5 | 15 | 30 | 50 | 150 | 250 | 160 | 500 | 330 | 1200 | 550 | |||

| 1/6 | 14 | 30 | 42 | 120 | 230 | 160 | 500 | 290 | 1100 | 530 | |||

| 1/7 | 14 | 30 | 42 | 120 | 230 | 160 | 500 | 290 | 1100 | 530 | |||

| 1/10 | 10 | 30 | 40 | 100 | 230 | 100 | 400 | 230 | 900 | 450 | |||

| L2 | 1/12 | 10 | 30 | 40 | 100 | 230 | 100 | 400 | 230 | 900 | 450 | ||

| 1/15 | 10 | 30 | 40 | 100 | 230 | 100 | 400 | 230 | 900 | 450 | |||

| 1/16 | 15 | 30 | 50 | 150 | 250 | 160 | 500 | 330 | 1200 | 550 | |||

| 1/20 | 15 | 30 | 50 | 150 | 250 | 160 | 500 | 330 | 1200 | 550 | |||

| 1/25 | 15 | 30 | 50 | 150 | 250 | 160 | 500 | 330 | 1200 | 550 | |||

| 1/28 | 15 | 30 | 50 | 150 | 250 | 160 | 500 | 330 | 1100 | 550 | |||

| 1/30 | 10 | 30 | 40 | 100 | 230 | 100 | 450 | 330 | 900 | 450 | |||

| 1/35 | 15 | 30 | 50 | 150 | 250 | 160 | 500 | 330 | 1100 | 550 | |||

| 1/40 | 15 | 30 | 50 | 150 | 250 | 160 | 500 | 330 | 1100 | 550 | |||

| 1/50 | 15 | 30 | 50 | 150 | 250 | 160 | 500 | 330 | 1100 | 550 | |||

| 1/60 | 15 | 30 | 50 | 150 | 250 | 160 | 500 | 330 | 1100 | 550 | |||

| 1/70 | 12 | 30 | 50 | 120 | 250 | 160 | 500 | 290 | 1100 | 550 | |||

| 1/100 | 10 | 30 | 40 | 100 | 230 | 100 | 400 | 230 | 900 | 450 | |||

| Max. Output Torque | Nm | L1,L2 | 3-100 | 3 Times of Normal Output Torque | |||||||||

| Input Speed | Rpm | L1,L2 | 3-100 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 |

| Standard Backlash | Arcmin | L1 | 3-10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 |

| L2 | 12-100 | ≤15 | ≤15 | ≤15 | ≤15 | ≤15 | ≤15 | ≤15 | ≤15 | ≤15 | ≤15 | ||

| Precision Backlash B2 | Arcmin | L1 | 3-10 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 |

| L2 | 12-100 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ||

| Precision Backlash B1 | Arcmin | L1 | 3-10 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | |

| L2 | 12-100 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | |||

| Max. Radial Force | N | L1,L2 | 3-100 | 1100 | 3250 | 3250 | 5850 | 9100 | 9100 | 14300 | 14300 | 19500 | 19500 |

| Max. Axial Force | N | L1,L2 | 3-100 | 650 | 3250 | 3250 | 5850 | 9100 | 9100 | 14300 | 14300 | 19500 | 19500 |

| Efficiency | % | L1 | 3-10 | 90% | |||||||||

| L2 | 12-100 | 85% | |||||||||||

| Weight | Kg | L1 | 3-10 | 1.8 | 2.9 | 3.8 | 10.5 | 15.5 | 12.5 | 31 | 25.5 | 56.5 | 37.5 |

| L2 | 12-100 | 2.1 | 3.3 | 4.3 | 11.2 | 17 | 13.2 | 35.5 | 28.5 | 63.5 | 42 | ||

| Operating Temp. | ℃ | L1,L2 | 3-100 | (-10℃~+80℃) | |||||||||

| Lubrication | L1,L2 | 3-100 | COMPLEX HV2 | ||||||||||

| Mounting Position | L1,L2 | 3-100 | Any Direction | ||||||||||

| Noise Level | dB(A) | L1,L2 | 3-100 | ≤68 | ≤68 | ≤68 | ≤68 | ≤70 | ≤70 | ≤72 | ≤72 | ≤74 | ≤74 |

Dimensions

Input Dimensions

FAQ

1. What’s your delivery time?

Lead time: Normally 15-25 days after confirm your deposit. Products in stock will be delivered 3-5 days after your deposit.

2. What’s your MOQ?

MOQ is 1 PC

3. How long is your warranty?

Warranty: 1 year

4. Planetary gearbox can be customized?

Yes, please send your servo motor dimensions drawing.

5. Where is the gearbox manufactured?

Produced in Taiwan.

6. Your gearbox was ever shipped to which countries?

Our gearbox has been sold to various countries like Russia, Vietnam, Canada, Australia, UAE, Japan etc..

7.You are a factory or trading company?

We are factory, the manufacture