Features

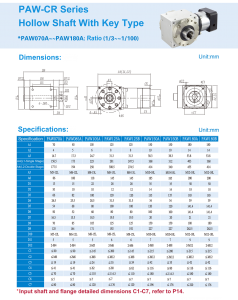

PAW-CR is the hollow shaft with keyway right angle spiral bevel gearbox.Hollow output design allows the axis to go through the hollow shaft directly without any installation accessories.

PAW-CR right angle gearbox has a abroad range of reduction from 1:3 to 1:100.The precision from 3arcmin to 15arcmin meets the customer's different precision requirements.

Spiral bevel gear adopts high strength SCM415 material with tooth surface hardness of HRC60 °~ HRC62 °,which makes the 90 degree gearbox rotate smoothly with low noise.

The high efficiency combination of planetary body structure and precise spiral bevel features PAW-CR spiral bevel gearbox a compact structure and can be easy installed by 5 directions.

The 90 degree servo gear box has excellent rigid structure for the output loading changes especially for big occasions.PAW-CR has more than 7 methods which is applicable for a variety of industrial machinery uses in transmission mechanism.

PAW-CR right angle gear box has multiple designs that earned patents across countries.

Widely used in Printer, Belt Conveyors, Gantry Robot, Auto packing sealing machine, Packing machine (vertical pillow), Packing machine (horizontal pillow), Dispenser Robot, Loader robot and some other heavy load case.

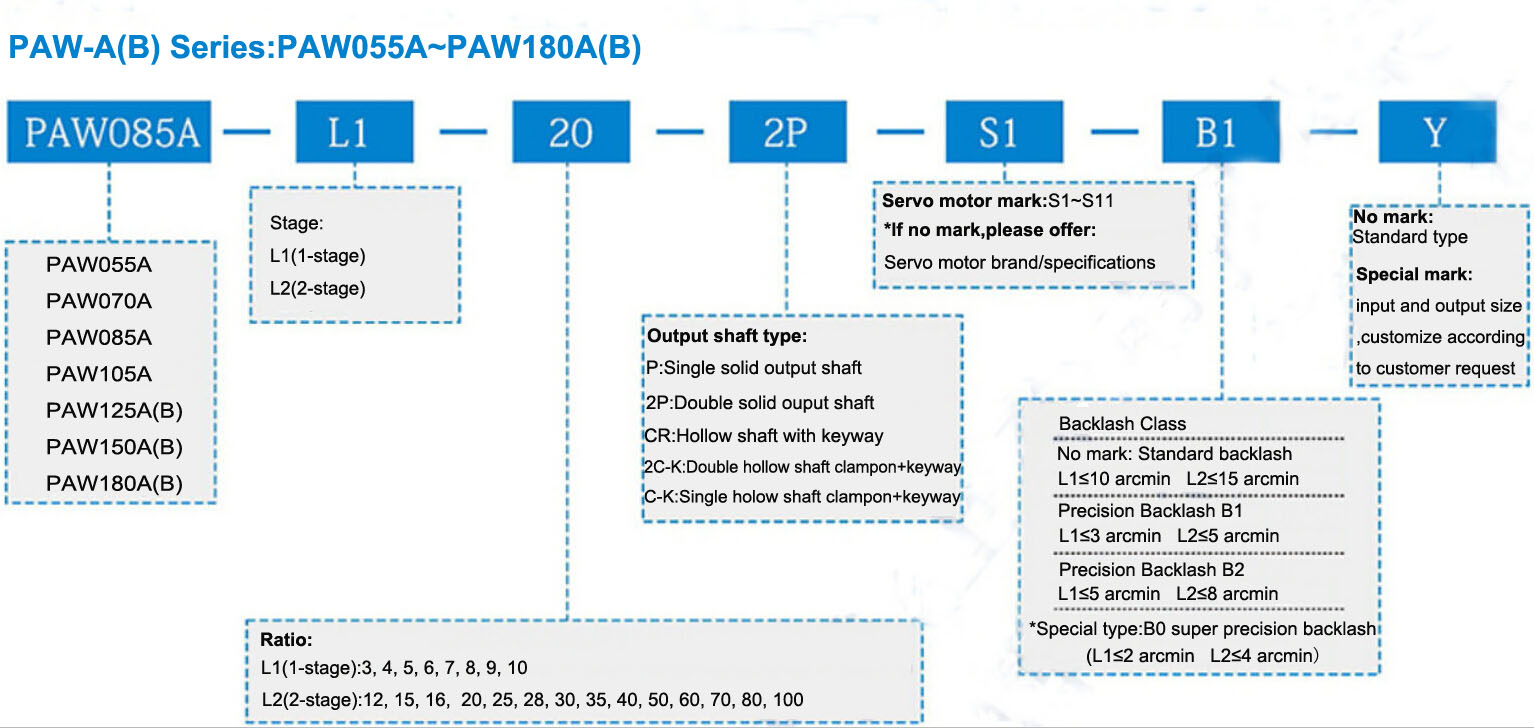

Model Indication

Parameters

| Model No. | Unit | Stage | Ratio(i) | PAW055A | PAW070A | PAW085A | PAW105A | PAW125A | PAW125B | PAW150A | PAW150B | PAW180A | PAW180B |

| Rated Output Torque | Nm | L1 | 1/3 | 10 | 30 | 40 | 100 | 230 | 100 | 400 | 230 | 900 | 450 |

| 1/4 | 15 | 30 | 50 | 150 | 250 | 160 | 500 | 330 | 1100 | 550 | |||

| 1/5 | 15 | 30 | 50 | 150 | 250 | 160 | 500 | 330 | 1200 | 550 | |||

| 1/6 | 14 | 30 | 42 | 120 | 230 | 160 | 500 | 290 | 1100 | 530 | |||

| 1/7 | 14 | 30 | 42 | 120 | 230 | 160 | 500 | 290 | 1100 | 530 | |||

| 1/10 | 10 | 30 | 40 | 100 | 230 | 100 | 400 | 230 | 900 | 450 | |||

| L2 | 1/12 | 10 | 30 | 40 | 100 | 230 | 100 | 400 | 230 | 900 | 450 | ||

| 1/15 | 10 | 30 | 40 | 100 | 230 | 100 | 400 | 230 | 900 | 450 | |||

| 1/16 | 15 | 30 | 50 | 150 | 250 | 160 | 500 | 330 | 1200 | 550 | |||

| 1/20 | 15 | 30 | 50 | 150 | 250 | 160 | 500 | 330 | 1200 | 550 | |||

| 1/25 | 15 | 30 | 50 | 150 | 250 | 160 | 500 | 330 | 1200 | 550 | |||

| 1/28 | 15 | 30 | 50 | 150 | 250 | 160 | 500 | 330 | 1100 | 550 | |||

| 1/30 | 10 | 30 | 40 | 100 | 230 | 100 | 450 | 330 | 900 | 450 | |||

| 1/35 | 15 | 30 | 50 | 150 | 250 | 160 | 500 | 330 | 1100 | 550 | |||

| 1/40 | 15 | 30 | 50 | 150 | 250 | 160 | 500 | 330 | 1100 | 550 | |||

| 1/50 | 15 | 30 | 50 | 150 | 250 | 160 | 500 | 330 | 1100 | 550 | |||

| 1/60 | 15 | 30 | 50 | 150 | 250 | 160 | 500 | 330 | 1100 | 550 | |||

| 1/70 | 12 | 30 | 50 | 120 | 250 | 160 | 500 | 290 | 1100 | 550 | |||

| 1/100 | 10 | 30 | 40 | 100 | 230 | 100 | 400 | 230 | 900 | 450 | |||

| Max. Output Torque | Nm | L1,L2 | 3-100 | 3 Times of Normal Output Torque | |||||||||

| Input Speed | Rpm | L1,L2 | 3-100 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 |

| Standard Backlash | Arcmin | L1 | 3-10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 |

| L2 | 12-100 | ≤15 | ≤15 | ≤15 | ≤15 | ≤15 | ≤15 | ≤15 | ≤15 | ≤15 | ≤15 | ||

| Precision Backlash B2 | Arcmin | L1 | 3-10 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 |

| L2 | 12-100 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ||

| Precision Backlash B1 | Arcmin | L1 | 3-10 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | |

| L2 | 12-100 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | |||

| Max. Radial Force | N | L1,L2 | 3-100 | 1100 | 3250 | 3250 | 5850 | 9100 | 9100 | 14300 | 14300 | 19500 | 19500 |

| Max. Axial Force | N | L1,L2 | 3-100 | 650 | 3250 | 3250 | 5850 | 9100 | 9100 | 14300 | 14300 | 19500 | 19500 |

| Efficiency | % | L1 | 3-10 | 90% | |||||||||

| L2 | 12-100 | 85% | |||||||||||

| Weight | Kg | L1 | 3-10 | 1.8 | 2.9 | 3.8 | 10.5 | 15.5 | 12.5 | 31 | 25.5 | 56.5 | 37.5 |

| L2 | 12-100 | 2.1 | 3.3 | 4.3 | 11.2 | 17 | 13.2 | 35.5 | 28.5 | 63.5 | 42 | ||

| Operating Temp. | ℃ | L1,L2 | 3-100 | (-10℃~+80℃) | |||||||||

| Lubrication | L1,L2 | 3-100 | COMPLEX HV2 | ||||||||||

| Mounting Position | L1,L2 | 3-100 | Any Direction | ||||||||||

| Noise Level | dB(A) | L1,L2 | 3-100 | ≤68 | ≤68 | ≤68 | ≤68 | ≤70 | ≤70 | ≤72 | ≤72 | ≤74 | ≤74 |

Dimensions

Input sizes

FAQ

1. What’s your delivery time?

Lead time: Normally 15-25 days after confirm your deposit. Products in stock will be delivered 3-5 days after your deposit.

2. What’s your MOQ?

MOQ is 1 PC

3. How long is your warranty?

Warranty: 1 year

4. Planetary gearbox can be customized?

Yes, please send your servo motor dimensions drawing.

5. Where is the gearbox manufactured?

Produced in Taiwan.

6. Your gearbox was ever shipped to which countries?

Our gearbox has been sold to various countries like Russia, Vietnam, Canada, Australia, UAE, Japan etc..

7.You are a factory or trading company?

We are factory, the manufacture