Features

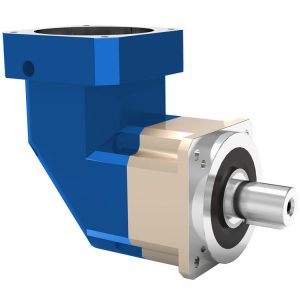

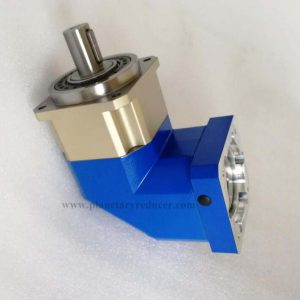

FHTW PAR gearbox is a type of high quality and low backlash right angle gearbox. PAR right angle planetary gearbox is with shaft output ,and the output side flange is square,which makes the gearbox easily install to the motion system. PAR series planetary gearbox use spiral bevel gears to realize the motor mounting with 90 degree bending, it performs smoothly with low noise and high rigidity.PAR right angle gearbox is not only the ideal option for the motion control system with limited space, but also the best choice for the transmission occasion that needs to change the motion direction. So it can help users to save the running cost and improve the transmission efficiency.

PAR right angle gearbox has the frame size:42mm,60mm,90mm,115mm,142mm,180mm,220mm.

PAR has a large range of ratio:3, 4, 5, 6, 7, 8, 9, 10, 14, 20 for single stage;15,20,25,30,35,40,50,70,80,100,120,140,160,180,200 for double stage.

Features of PAR right angle planetgary gearbox

1.Space-Saving

Rectangular reducer use spiral bevel gears to make motor mounted in 90 degree bending, that is, save space.

2.High rigidity and torque

The rigidity and torque are heavily enhanced by using one-piece roller bearing.

3.Methods of connector and bush.

Can be installed on any motor all over the world.

4.No leakage of grease

Use high viscosity and non-separated grease to avoid the leakage.

5. Convenient Maintenance.

No need change the grease with the service time of reducer, install much conveniently.

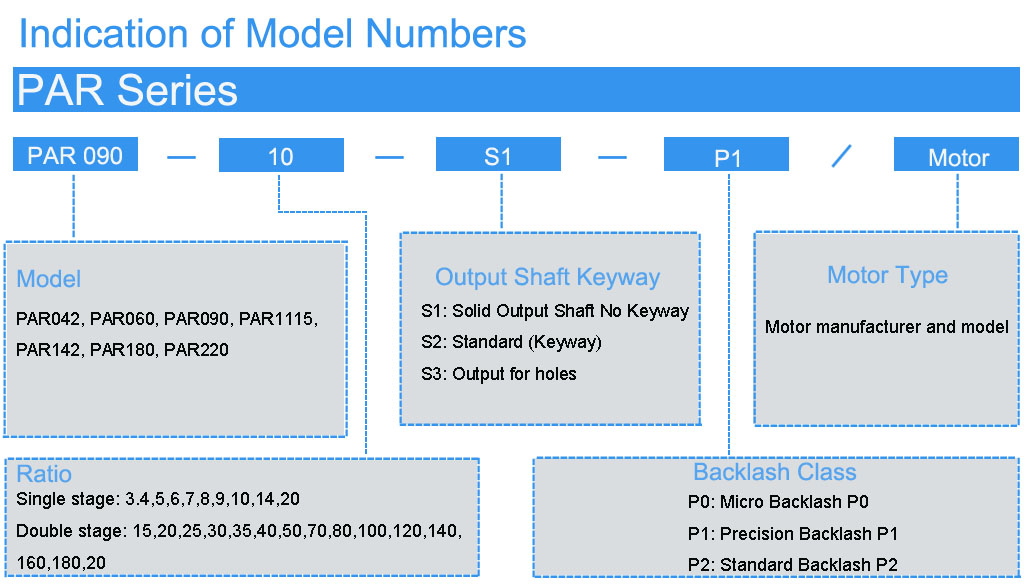

Model Selection

Before choosing a gearbox, Please specify the gear ratio you need. After determine a ratio, multiplying your servo motor rated torque by the ratio, the value should be in principle less than our gearbox rated output torque which can be found int the data sheets. Take other overloads which drive the motor into consideration, to choose the max. Operating torque, this should not exceed 2 times of our gearbox rated torque.

After determine the above, you can choose a smallest volume gearbox to save cost.

You can send us the servo motor dimension drawing for model selection or advise the specific servo motor model number.

If you have special requirement for the precision, Please clarify.

PAR series planetary reducers are widely used in Printer, Belt Conveyer, Gantry Robot, Auto packing sealing machine, Packing machine ( vertical pillow), Packing machine ( horizontal pillow), Dispenser Robot, Loader robot etc.

Parameters

| Model No. | Unit | Stage | Ratio | PAR042 | PAR060 | PAR090 | PAR115 | PAR142 | PAR180 | PAR220 |

| Rated Output Torque | Nm | 1 | 3 | 13 | 50 | 150 | 310 | 550 | 1100 | 1860 |

| 4 | 16 | 55 | 153 | 330 | 600 | 1250 | 1950 | |||

| 5 | 15 | 53 | 152 | 325 | 590 | 1200 | 1900 | |||

| 6 | 11 | 45 | 130 | 250 | 450 | 950 | 1600 | |||

| 7 | 15 | 50 | 140 | 300 | 540 | 1050 | 1760 | |||

| 8 | 11 | 45 | 110 | 260 | 460 | 960 | 1550 | |||

| 9 | 9 | 40 | 100 | 230 | 450 | 900 | 1500 | |||

| 10 | 12 | 48 | 128 | 280 | 520 | 1000 | 1120 | |||

| 14 | 13 | 42 | 120 | 265 | 500 | 1020 | 1100 | |||

| 20 | 10 | 42 | 115 | 255 | 500 | 980 | 1100 | |||

| 2 | 15 | 13 | 50 | 150 | 300 | 530 | 1100 | 1800 | ||

| 20 | 15 | 52 | 150 | 300 | 530 | 1150 | 1800 | |||

| 25 | 15 | 53 | 150 | 325 | 590 | 1200 | 1800 | |||

| 30 | 13 | 49 | 150 | 310 | 550 | 1100 | 1830 | |||

| 35 | 13 | 50 | 140 | 300 | 540 | 1100 | 1800 | |||

| 40 | 15 | 45 | 140 | 260 | 500 | 1000 | 1600 | |||

| 50 | 15 | 50 | 135 | 230 | 580 | 1200 | 1670 | |||

| 70 | 13 | 50 | 130 | 300 | 520 | 1100 | 1600 | |||

| 80 | 11 | 40 | 100 | 260 | 500 | 1000 | 1500 | |||

| 100 | 10 | 40 | 100 | 230 | 450 | 900 | 1500 | |||

| 120 | 130 | 310 | 500 | 1100 | 1900 | |||||

| 140 | 130 | 300 | 530 | 1100 | 1800 | |||||

| 160 | 120 | 260 | 520 | 1000 | 1600 | |||||

| 180 | 100 | 230 | 450 | 900 | 1500 | |||||

| 200 | 100 | 230 | 450 | 900 | 1500 | |||||

| Max. Output Torque | Nm | 1,2 | 3-200 | 3 Times of Normal Output Torque | ||||||

| Rated Input Speed | Rpm | 1,2 | 3-200 | 3000 | 3000 | 3000 | 3000 | 2500 | 2000 | 2000 |

| Max. Input Speed | Rpm | 1,2 | 3-200 | 6000 | 6000 | 6000 | 5500 | 4500 | 4500 | 4000 |

| Precision Backlash P1 | Arcmin | 1 | 3-20 | ≤6 | ≤6 | ≤6 | ≤6 | ≤6 | ≤6 | ≤6 |

| 2 | 15-200 | ≤9 | ≤9 | ≤9 | ≤9 | ≤9 | ≤9 | ≤9 | ||

| Standard Backlash P2 | Arcmin | 1 | 3-20 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 |

| 2 | 15-200 | ≤13 | ≤13 | ≤13 | ≤13 | ≤13 | ≤13 | ≤13 | ||

| Torsional Rigidity | Nm/arcmin | 1,2 | 3-200 | 3 | 6 | 14 | 25 | 56 | 140 | 220 |

| Max. Radial Force | N | 1,2 | 3-200 | 780 | 1300 | 3200 | 6750 | 9400 | 14500 | 50000 |

| Max. Axial Force | N | 1,2 | 3-200 | 330 | 700 | 1580 | 3300 | 4700 | 7200 | 28000 |

| Service Life | Hr | 1,2 | 3-200 | 21000hrs | ||||||

| Efficiency | % | 1 | 3-20 | ≥93% | ||||||

| 2 | 25-200 | ≥90% | ||||||||

| Weight | Kg | 1 | 3-20 | 0.9 | 2.1 | 6.4 | 13 | 24.5 | 51 | 83 |

| 2 | 25-200 | 1.2 | 1.5 | 7.8 | 14.2 | 27.5 | 54 | 95 | ||

| Operating Temperature | ℃ | 1,2 | 3-200 | (-15℃~+90℃) | ||||||

| Lubrication | 1,2 | 3-200 | Synthetic Grease | |||||||

| Protection Class | 1,2 | 3-200 | IP65 | |||||||

| Mounting Position | 1,2 | 3-200 | Any Direction | |||||||

| Noise Level | dB(A) | 1,2 | 3-200 | ≤65 | ≤65 | ≤68 | ≤68 | ≤70 | ≤72 | ≤74 |

Moment of Inertia

| Model No. | Unit | Stage | Ratio | PAR042 | PAR060 | PAR090 | PAR115 | PAR142 | PAR180 | PAR220 |

| Moment of Inertia | kg.cm2 | 1 | 3~10 | 0.09 | 0.35 | 2.25 | 6.84 | 23.4 | 68.9 | 135.4 |

| 14-20 | 0.03 | 0.07 | 1.87 | 6.25 | 21.8 | 65.6 | 119.8 | |||

| 2 | 15-100 | 0.09 | 0.09 | 0.35 | 2.25 | 6.84 | 23.4 | 68.9 | ||

| 120-200 | * | * | 0.31 | 1.87 | 6.25 | 21.8 | 65.6 |

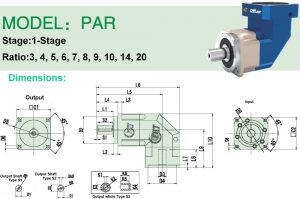

Dimensions

Reducer Dimensions:

(1) Single stage(Ratio: 3, 4, 5,6,7,8,9,10,14,20)

Unit:mm

| Size | PAR042-L1 | PAR060-L1 | PAR090-L1 | PAR115-L1 | PAR142-L1 | PAR180-L1 | PAR220-L1 |

| D1 | Φ13 | Φ16 | Φ22 | Φ32 | Φ40 | Φ55 | Φ75 |

| D2 | Φ35 | Φ50 | Φ80 | Φ110 | Φ130 | Φ160 | Φ180 |

| D3 | Φ8(≤11) | Φ14(≤14) | Φ19(≤24) | Φ24(≤32) | Φ35(≤42) | Φ38(≤50) | Φ55(≤55) |

| D4 | Φ30(30-50) | Φ50(30-70) | Φ70(50-110) | Φ110(50-130) | Φ114.3(95-180) | Φ180(95-180) | Φ215(180-255) |

| D5 | Φ50 | Φ70 | Φ100 | Φ130 | Φ165 | Φ215 | Φ250 |

| D6 | 4-Φ3.4 | 4-Φ5.5 | 4-Φ6.6 | 4-Φ9 | 4-Φ11 | 4-Φ13 | 4-Φ17 |

| D7 | Φ46(22-70) | Φ70(45-90) | Φ90(70-145) | Φ145(70-145) | Φ200(90-215) | Φ200(90-300) | Φ235(200-300) |

| D8 | (4-M3X8L) | (4-M5X10L) | (4-M6X12L) | (4-M8X25L) | (4-M12X30L) | (4-M12X30L) | (4-M12X30L) |

| D9 | M4X0.7P | M5X0.8P | M8X1.25P | M12X1.75P | M16X2.0P | M20X2.5P | M20X2.5P |

| L1 | 19 | 28.5 | 36.5 | 51 | 79 | 82 | 105 |

| L2 | 5.5 | 7 | 10 | 12 | 15 | 20 | 30 |

| L3 | 4 | 6 | 8 | 10 | 12 | 15 | 20 |

| L4 | 26 | 37 | 48 | 65 | 97 | 105 | 138 |

| L5 | (96) | (117) | (175) | (227) | (255) | (289) | (346) |

| L6 | (122) | (154) | (223) | (292) | (352) | (394) | (484) |

| L7 | (3.5) | (5) | (5) | (11) | (14) | (15) | (7) |

| L8 | (30) | (34) | (44) | (60) | (81) | (85) | (85) |

| L9 | 69.5 | 81.5 | 107.5 | 134 | 165 | 213.5 | 268.5 |

| L10 | 95.5 | 110.5 | 158 | 199 | 230 | 303.5 | 378.5 |

| C1 | □42 | □60 | □90 | □115 | □142 | □180 | □220 |

| C2 | (□42) | (□60) | (□90) | (□130) | (□142) | (□180) | (□220) |

| S1 | 2 | 2 | 2 | 5 | 5 | 5 | 7 |

| S2 | 16 | 25 | 32 | 40 | 65 | 70 | 90 |

| S3 | 15 | 18 | 24.5 | 35 | 43 | 59 | 79 |

| B | 5 | 5 | 6 | 10 | 12 | 16 | 20 |

| K1 | 3 | 4 | 6 | 8 | 10 | 14 | 16 |

| K2 | Φ8 | Φ11 | Φ22 | Φ28 | Φ38 | Φ50 | Φ60 |

| K3 | 9.2 | 12.7 | 25 | 31.3 | 42 | 53.8 | 64.4 |

| K4 | Φ13 | Φ16 | Φ32 | Φ38 | Φ48 | Φ60 | Φ72 |

| K5 | 15 | 15 | 20 | 27 | 35 | 43 | 60 |

| K6 | 18 | 18 | 24 | 32 | 40 | 50 | 65 |

Note 1:Inside of ()is the optional range of sizes,outside of ()is the standard sizes.

Note 2:The reducer output shaft size and length can be customized for customers.

Note 3:Input sizes can be subject to changed according to kinds of servo motor or stepper motor size.

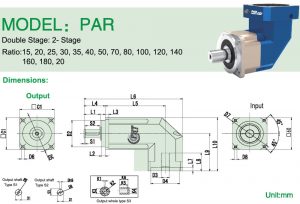

(2) Double stage(Ratio: 15,20,25,30,35,40,50,70,80,100,120,140,160,180,200)

unit:mm

| Size | PAR042-L2 | PAR060-L2 | PAR090-L2 | PAR115-L2 | PAR142-L2 | PAR180-L2 | PAR220-L2 |

| D1 | Φ13 | Φ16 | Φ22 | Φ32 | Φ40 | Φ55 | Φ75 |

| D2 | Φ35 | Φ50 | Φ80 | Φ110 | Φ130 | Φ160 | Φ180 |

| D3 | Φ8(≤11) | Φ14(≤14) | Φ19(≤24) | Φ24(≤32) | Φ35(≤42) | Φ38(≤50) | Φ55(≤55) |

| D4 | Φ30(30-50) | Φ50(30-70) | Φ70(50-110) | Φ110(50-130) | Φ114.3(95-180) | Φ180(95-180) | Φ215(180-255) |

| D5 | Φ50 | Φ70 | Φ100 | Φ130 | Φ165 | Φ215 | Φ250 |

| D6 | 4-Φ3.4 | 4-Φ5.5 | 4-Φ6.6 | 4-Φ9 | 4-Φ11 | 4-Φ13 | 4-Φ17 |

| D7 | Φ46(22-70) | Φ70(45-90) | Φ90(70-145) | Φ145(70-145) | Φ200(90-215) | Φ200(90-300) | Φ235(200-300) |

| D8 | (4-M3X8L) | (4-M5X10L) | (4-M6X12L) | (4-M8X25L) | (4-M12X30L) | (4-M12X30L) | (4-M12X30L) |

| D9 | M4X0.7P | M5X0.8P | M8X1.25P | M12X1.75P | M16X2.0P | M20X2.5P | M20X2.5P |

| L1 | 19 | 28.5 | 36.5 | 51 | 79 | 82 | 105 |

| L2 | 5.5 | 7 | 10 | 12 | 15 | 20 | 30 |

| L3 | 4 | 6 | 8 | 10 | 12 | 15 | 20 |

| L4 | 26 | 37 | 48 | 65 | 97 | 105 | 138 |

| L5 | (113) | (134) | (157) | (224) | (282) | (322) | (383) |

| L6 | 139 | 171 | 205 | (292) | (378) | (427) | (521) |

| L7 | (3.5) | (5) | (5) | (11) | (14) | (15) | (7) |

| L8 | (30) | (34) | (44) | (60) | (81) | (85) | (85) |

| L9 | (69.5) | (81.5) | (107.5) | (134) | (165) | (213.5) | (268.5) |

| L10 | (90.5) | (111.5) | (152.5) | (191.5) | (236) | (303.5) | (378.5) |

| C1 | □42 | □60 | □90 | □115 | □142 | □180 | □220 |

| C2 | (□42) | (□60) | (□90) | (□130) | (□142) | (□180) | (□220) |

| S1 | 2 | 2 | 2 | 5 | 5 | 5 | 7 |

| S2 | 16 | 25 | 32 | 40 | 65 | 70 | 90 |

| S3 | 15 | 18 | 24.5 | 35 | 43 | 59 | 79 |

| B | 5 | 5 | 6 | 10 | 12 | 16 | 20 |

| K1 | 3 | 4 | 6 | 8 | 10 | 14 | 16 |

| K2 | Φ8 | Φ11 | Φ22 | Φ28 | Φ38 | Φ50 | Φ60 |

| K3 | 9.2 | 12.7 | 25 | 31.3 | 42 | 53.8 | 64.4 |

| K4 | Φ13 | Φ16 | Φ32 | Φ38 | Φ48 | Φ60 | Φ72 |

| K5 | 15 | 15 | 20 | 27 | 35 | 43 | 60 |

| K6 | 18 | 18 | 24 | 32 | 40 | 50 | 65 |

Note 1:Inside of ()is the optional range of sizes,outside of ()is the standard sizes.

Note 2:The reducer output shaft size and length can be customized for customers.

Note 3:Input sizes can be subject to changed according to kinds of servo motor or stepper motor size.

Download

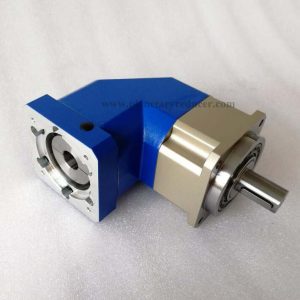

Real Pictures

Single Stage Ratio

Double stage ratio