Features

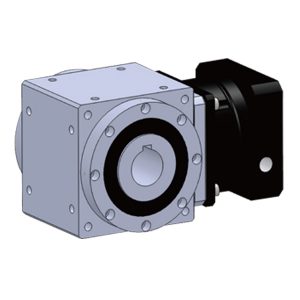

AATM-CR right angle gear has one input flange and output flange with keyway.We always call it spiral bevel gearbox or right angle planetary gearbox.Since it consists of high efficiency planetary frame and precision spiral bevel gear.

Nominal torques of AATM-CR right angle gearbox is 30~4000Nm,applicable for various drive systems with high rotation torque.

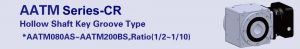

AATM-CR right angle spiral bevel gearbox only has the ratio from 1:2 to 1:10

AATM-CR is a low backlash right angle gearbox: 1arcmin~5arcmin

High efficiency( ≥ 90%) makes the spiral bevel gearbox rotate with low noise and generate less heat.

The hollow shaft right angle gearbox has five sizes available: AATM080AS / AATM110AS / AATM135AS / AATM165AS / AATM200BS.

Application

Widely used in Printer, Belt Conveyors, Gantry Robot, Auto packing sealing machine, Packing machine ( vertical pillow), Packing machine ( horizontal pillow), Dispenser Robot, Loader robot and some other heavy load case.

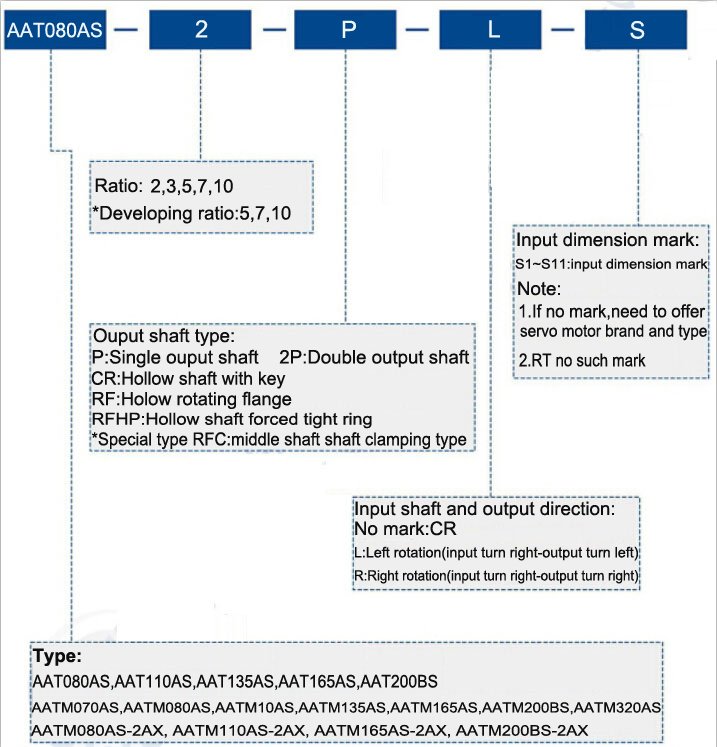

Model indication

Parameters

| Model No. | Stage | Ratio(i) | AATM080AS | AATM110AS | AATM135AS | AATM165AS | AATM200BS |

| Rated Output Torque(Nm) | L1 | 2, 3, 5, 10 | 80 | 250 | 450 | 800 | * |

| 6 | 80 | 200 | 400 | 700 | 1000 | ||

| 8 | 85 | 250 | 450 | 800 | 1100 | ||

| 10 | 85 | 250 | 450 | 800 | 1100 | ||

| Max. Output Torque(Nm) | L1,L2 | 3~100 | 2.5 Times of Normal Output Torque | ||||

| Input Speed(rpm) | L1,L2 | 3~100 | 3000 | 3000 | 3000 | 3000 | 3000 |

| Standard Back-lash (arc-min) | L1 | 3~10 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 |

| L2 | 12~100 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | |

| Precision Backlash B2(arc-min) | L1 | 3~10 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 |

| L2 | 12~100 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | |

| Precision BacklashB1(arc-min) | L1 | 3~10 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 |

| L2 | 12~100 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | |

| Precision Backlash B0(arc-min) | L1 | 3~10 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

| L2 | 12~100 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | |

| Max. Radial Force(N) | L1,L2 | 3~100 | 3900 | 5500 | 9800 | 16500 | 24100 |

| Max. Axial Force(N) | L1,L2 | 3~100 | 3900 | 5500 | 9800 | 16500 | 24100 |

| Efficiency(%) | L1 | 3~10 | 90% | ||||

| L2 | 12~100 | 85% | |||||

| Weight(kg) | L1 | 3~10 | 7.8 | 4.3 | 20.8 | 35.5 | 40.5 |

| L2 | 12~100 | 9.2 | 6.3 | 24.3 | 40.5 | 48.5 | |

| Operating Temp. | L1,L2 | 3~100 | -10℃~+80℃ | ||||

| Lubrication | L1,L2 | 3~100 | COMPLEX HV2 | ||||

| Mounting Position | L1,L2 | 3~100 | Any Direction | ||||

| Noise Level (db) | L1,L2 | 3~100 | ≤68 | ≤68 | ≤68 | ≤70 | ≤72 |

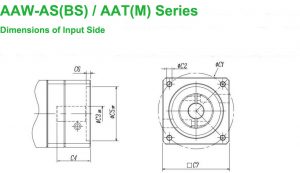

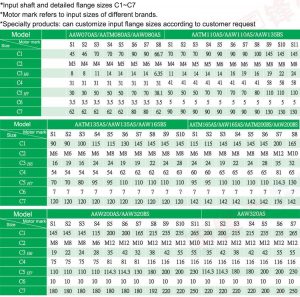

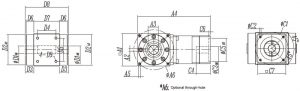

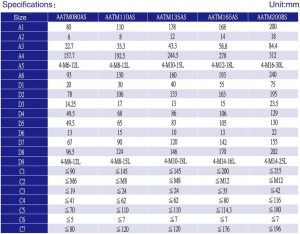

Dimension

Input Size