Features

HK series screw lift, also named jack, it has many functions such as raising, falling, pushing by means of auxiliaries, turn over etc. It has wide range of power sources: driven by motor or other power directly, by manual. Generally the lift is used in occasions of low speed and heavy load.

1.Compact structure, small volume, light weight

2.Extensive power source, no noise, convenient installation

3.Low speed, low frequency: Mainly used in occasions of heavy load, low speed, no frequent working.

4.Keep loading: The trapezoid screw rod has function of self locking, it can keep loading without brake.

5.Flexible applications, multiple functions, multiple match models, high reliability, long service time.

6.Can be used separately and used in a combination

7.The screw lift can accurately control and adjust the height of raising and pushing according to a certain procedure.

8.Can be driven directly by motor or other power, also manual is okay.

9.Own different structures and assemble types, the raising height can be customized as per customers’ requirements.

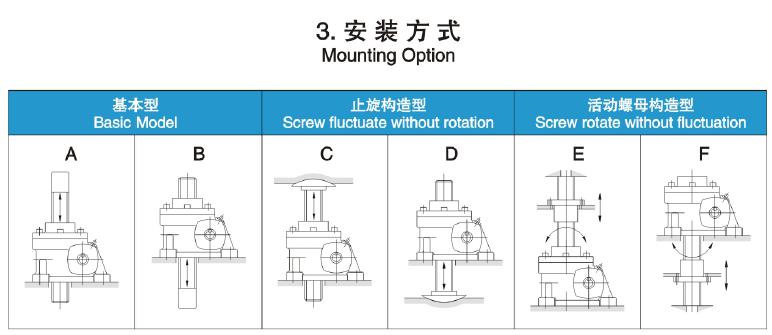

options

1: Basic type: Nut ( worm gear) rotate, screw rod move up and down, this is a ordinary mounting type of lift.

Note: There will be a rotated force when screw rod lift, so some measures must be taken to avoid rotating.

2: Structure of stop rotating: Suitable for operating when there is no connection on the top and all kinds of occasions which the non rotation can’t be realized

3. Structure of movable nut: If you want to lengthen the stroke in a limit space, choose this structure. The screw rod rotate, movable nut move. Of the stroke is longer, there should be a support at the end of shaft so that better transmission efficiency can be realized.

Model selection

parameters

| Model | Ratio | Input Shaft Speed 1800 r/min | Input Shaft Speed 1500 r/min | Input Shaft Speed 1200 r/min | Input Shaft Speed 900 r/min | Input Shaft Speed 600 r/min | Input Shaft Speed 300 r/min | ||||||||||||

| Power (Kw) | Lifting Force(Kg) | Lifting Speed (m/min) | Power (Kw) | Lifting Force (Kg) | Lifting Speed (m/min) | Power (Kw) | Lifting Force (Kg) | Lifting Speed (m/min) | Power (Kw) | Lifting Force(Kg) | Lifting Speed (m/min) | Power (Kw) | Lifting Force (Kg) | Lifting Speed (m/min) | Power (Kw) | Lifting Force(Kg) | Lifting Speed (m/min) | ||

| HK-2T | 1/5 | 0.69 | 500 | 1.8 | 0.64 | 550 | 1.5 | 0.65 | 700 | 1.2 | 0.63 | 900 | 0.9 | 0.46 | 1000 | 0.6 | 0.37 | 1000 | 0.3 |

| 1/10 | 0.37 | 500 | 0.9 | 0.37 | 550 | 0.75 | 0.37 | 700 | 0.6 | 0.37 | 950 | 0.45 | 0.37 | 1000 | 0.3 | 0.19 | 1350 | 0.15 | |

| 1/20 | 0.37 | 600 | 0.45 | 0.37 | 700 | 0.38 | 0.37 | 900 | 0.3 | 0.37 | 1200 | 0.23 | 0.19 | 1350 | 0.15 | 0.19 | 1350 | 0.08 | |

| HK-3T | 1/6 | 0.98 | 700 | 1.8 | 0.93 | 800 | 1.5 | 0.88 | 950 | 1.2 | 0.91 | 1300 | 0.9 | 0.84 | 1800 | 0.6 | 0.42 | 1800 | 0.3 |

| 1/12 | 0.68 | 950 | 0.9 | 0.64 | 1100 | 0.75 | 0.61 | 1300 | 0.6 | 0.57 | 1650 | 0.45 | 0.46 | 2000 | 0.3 | 0.37 | 2000 | 0.15 | |

| 1/24 | 0.37 | 950 | 0.45 | 0.37 | 1100 | 0.38 | 0.37 | 1300 | 0.3 | 0.37 | 1650 | 0.23 | 0.37 | 2000 | 0.15 | 0.19 | 2000 | 0.08 | |

| HK-5T | 1/6 | 1.39 | 900 | 1.8 | 1.28 | 1000 | 1.5 | 1.24 | 1200 | 1.2 | 1.16 | 1500 | 0.9 | 0.87 | 1700 | 0.6 | 0.54 | 2100 | 0.3 |

| 1/12 | 1.1 | 1350 | 0.9 | 1.01 | 1500 | 0.75 | 0.98 | 1800 | 0.6 | 0.87 | 2150 | 0.45 | 0.58 | 2150 | 0.3 | 0.37 | 2500 | 0.15 | |

| 1/24 | 0.78 | 1800 | 0.45 | 0.72 | 2000 | 0.38 | 0.69 | 2400 | 0.3 | 0.55 | 2550 | 0.23 | 0.42 | 2900 | 0.15 | 0.37 | 2850 | 0.08 | |

| HK-10T | 1/8 | 2.12 | 1300 | 1.8 | 1.97 | 1450 | 1.5 | 1.85 | 1700 | 1.2 | 1.72 | 2100 | 0.9 | 1.66 | 3050 | 0.6 | 1.31 | 4800 | 0.30 |

| 1/16 | 1.12 | 1300 | 0.9 | 1.04 | 1450 | 0.75 | 0.98 | 1700 | 0.6 | 0.95 | 2200 | 0.45 | 0.87 | 3050 | 0.3 | 0.69 | 4800 | 0.15 | |

| 1/32 | 0.8 | 1750 | 0.45 | 0.75 | 1950 | 0.38 | 0.69 | 2250 | 0.3 | 0.64 | 2800 | 0.23 | 0.63 | 4100 | 0.15 | 0.48 | 6400 | 0.08 | |

| HK-15T | 1/8 | 2 | 1300 | 1.8 | 1.86 | 1450 | 1.5 | 1.75 | 1700 | 1.2 | 1.62 | 2100 | 0.9 | 1.57 | 3050 | 0.6 | 1.24 | 4800 | 0.30 |

| 1/16 | 1.06 | 1300 | 0.9 | 0.98 | 1450 | 0.75 | 0.93 | 1700 | 0.6 | 0.89 | 2200 | 0.45 | 0.83 | 3050 | 0.3 | 0.65 | 4800 | 0.15 | |

| 1/32 | 0.75 | 1750 | 0.45 | 0.7 | 1950 | 0.38 | 0.65 | 2250 | 0.3 | 0.61 | 2800 | 0.23 | 0.59 | 4100 | 0.15 | 0.46 | 6400 | 0.08 | |

| HK-20T | 1/10 | 2.66 | 1400 | 1.8 | 2.42 | 1850 | 1.5 | 2.25 | 1950 | 1.2 | 2.12 | 2450 | 0.9 | 1.93 | 3350 | 0.6 | 1.41 | 4900 | 0.30 |

| 1/20 | 1.42 | 1600 | 0.9 | 1.47 | 1850 | 0.75 | 1.37 | 2250 | 0.6 | 1.28 | 2800 | 0.45 | 1.18 | 3850 | 0.3 | 0.86 | 5600 | 0.15 | |

| 1/40 | 1.14 | 2400 | 0.45 | 1.17 | 2800 | 0.38 | 1.09 | 3350 | 0.3 | 1.07 | 4400 | 0.23 | 0.93 | 5750 | 0.15 | 0.69 | 8400 | 0.08 | |

| HK-30T | 1/12 | 3.62 | 1850 | 1.8 | 3.51 | 2150 | 1.5 | 3.39 | 2600 | 1.2 | 3.18 | 3250 | 0.9 | 2.94 | 4500 | 0.6 | 2.09 | 6400 | 0.30 |

| 1/18 | 2.65 | 1900 | 1.2 | 2.68 | 2300 | 1 | 2.57 | 2750 | 0.8 | 2.45 | 3500 | 0.6 | 2.19 | 4700 | 0.4 | 1.56 | 6700 | 0.2 | |

| 1/36 | 1.66 | 2200 | 0.6 | 1.63 | 2600 | 0.5 | 1.6 | 3200 | 0.4 | 1.47 | 3900 | 0.3 | 1.36 | 5400 | 0.2 | 1.2 | 9600 | 0.1 | |

| HK-40T | 1/12 | 4.15 | 1975 | 1.8 | 4.02 | 2300 | 1.5 | 3.81 | 2725 | 1.2 | 3.8 | 3625 | 0.9 | 3.48 | 4975 | 0.6 | 2.48 | 7050 | 0.30 |

| 1/18 | 3.2 | 2125 | 1.2 | 3.2 | 2550 | 1 | 3.04 | 3025 | 0.8 | 3.03 | 4025 | 0.6 | 2.74 | 5450 | 0.4 | 1.94 | 7725 | 0.2 | |

| 1/36 | 2.14 | 2625 | 0.6 | 2.07 | 3050 | 0.5 | 1.98 | 3650 | 0.4 | 1.99 | 4875 | 0.3 | 1.8 | 6600 | 0.2 | 1.41 | 10300 | 0.1 | |

| HK-50T | 1/7 | 9.47 | 2100 | 3.6 | 9.1 | 2450 | 3 | 9.02 | 2850 | 2.4 | 8.58 | 4000 | 1.8 | 8.2 | 5450 | 1.2 | 5.84 | 7750 | 0.6 |

| 1/14 | 5.76 | 2350 | 1.8 | 5.71 | 2800 | 1.5 | 5.57 | 3300 | 1.2 | 5.39 | 4550 | 0.9 | 5.06 | 6200 | 0.6 | 3.57 | 8750 | 0.30 | |

| 1/28 | 4.07 | 3050 | 0.9 | 3.89 | 3500 | 0.75 | 3.91 | 4100 | 0.6 | 3.65 | 5850 | 0.45 | 3.48 | 7800 | 0.3 | 2.45 | 11000 | 0.15 | |

| HK-100T | 1/8 | 16.3 | 3500 | 3.6 | 16.1 | 4000 | 3 | 15.8 | 5400 | 2.4 | 15.1 | 7100 | 1.8 | 14.8 | 9850 | 1.2 | 9.7 | 12950 | 0.6 |

| 1/16 | 11.7 | 4300 | 1.8 | 11.6 | 5400 | 1.5 | 10.5 | 7200 | 1.2 | 11 | 9450 | 0.9 | 9.62 | 11800 | 0.6 | 7.08 | 17350 | 0.30 | |

| 1/32 | 8.65 | 5500 | 0.9 | 9.55 | 6800 | 0.75 | 7.35 | 10000 | 0.6 | 7.53 | 14300 | 0.45 | 7.02 | 15750 | 03 | 5.84 | 26050 | 0.15 | |

Application

Platform lifting, working height adjustment of surface processing machine, tilt level adjusting of sliding transmission belt, working height modification of corrector, automatic opening and closing of large scale windows and doors.

Installation

1.How to store the screw lift?

1)Keep the lift in a clean and dry place.

2)If it will be stored outdoor or in a humid place, please put the reducer in a box and packed tightly with plastic bag to avoid the rain and external erosion. ( take measure of anti-condensation and anti-rust)

5.Warranty instruction:

The following cost and damages are not included in our warranty:

1)Freight cost

2)If the lift connect with or insert in a unit, when we dismounting or mounting on the unit and other extra action, there will be a cost.( this is not contained in the warranty)

3)The indirect damage that user lost the appliance chance or business break off due to reducer breakdown.

4)Other derivative and accompanying damages.

Notes:

1.Please select the model with proper ratio and load.

2.The surface temperature of reducer and nut should be controlled in -15℃~80℃ when the lift working.

3.Do not make the lift work continuously. The load hour factor (T%) of one lift shouldn’t exceed 20%, the unit is 30 minutes.

Load factor T%=Time under working/Circle x100%

Time under working/circle+interval/circle

4.Ensure the sufficient power for drive source

5.In theory, the lift has function of self locking, while the function will be out of order when there are large impact and vibration.

6.Working conditions:

Place: No rain intrude

Surrounding air: Normal standard of a factory

Ambient temperature: -15℃~40℃

Relative Humidity: Below 85%