Features

PT-CR steering gearbox is with hollow output shaft and solid input shaft.The Hollow output design allows the axis to go through the hollow shaft directly without any installation accessories.

The gear adopts high strength SCM415 material with tooth surface hardness of HRC60 °~ HRC62 °,which makes the 90 degree gearbox rotate smoothly with low noise.The 90 degree servo gear box has excellent rigid structure for the output loading changes especially for big occasions.

PT-CR right angle gear box has multiple designs that earned patents across countries.PT-CR steering gearbox has six frame types: PT070A,PT085A,PT105A,PT125B,PT150B,PT180B. The ratio is 1:1,suitable for the transmission mechanism that requires to change the motion direction with the same speed.

PT-CR is widely used in Printer, Belt Conveyors, Gantry Robot, Auto packing sealing machine, Packing machine (vertical pillow), Packing machine (horizontal pillow), Dispenser Robot, Loader robot and some other heavy load case.

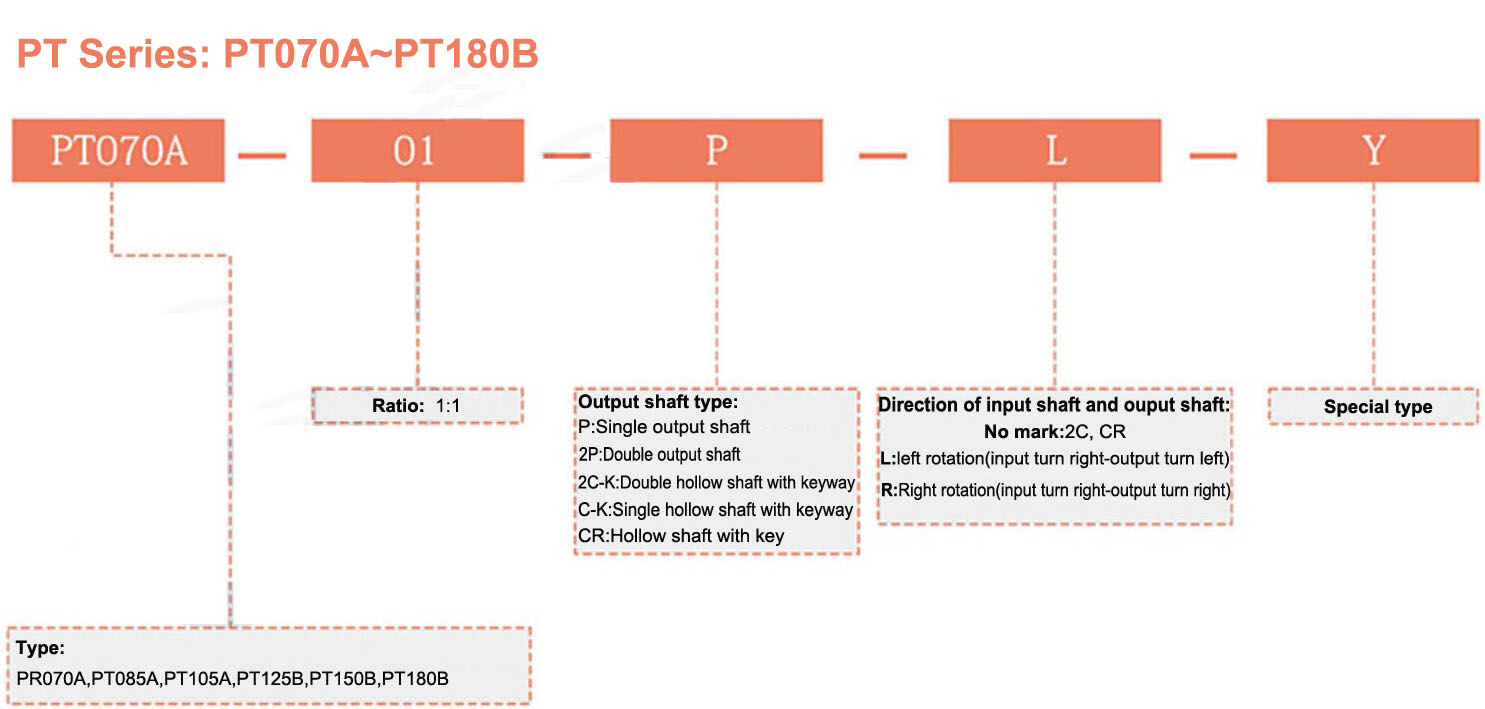

Model indication

Parameters

| Model No. | Unit | Stage | Ratio(i) | PT070A | PT085A | PT105A | PT125B | PT150B | PT180B |

| Rated Output Torque | Nm | L1 | 1/1 | 30 | 40 | 100 | 230 | 400 | 600 |

| 1/3 | 30 | 40 | 100 | 230 | 400 | 450 | |||

| 1/4 | 30 | 50 | 150 | 250 | 500 | 550 | |||

| 1/5 | 30 | 50 | 150 | 250 | 500 | 550 | |||

| 1/6 | 30 | 42 | 120 | 230 | 500 | 530 | |||

| 1/7 | 30 | 42 | 120 | 230 | 500 | 530 | |||

| 1/10 | 30 | 40 | 100 | 230 | 400 | 450 | |||

| L2 | 1/12 | 30 | 40 | 100 | 230 | 400 | 450 | ||

| 1/15 | 30 | 40 | 100 | 230 | 400 | 450 | |||

| 1/16 | 30 | 50 | 150 | 250 | 500 | 550 | |||

| 1/20 | 30 | 50 | 150 | 250 | 500 | 550 | |||

| 1/25 | 30 | 50 | 150 | 250 | 500 | 550 | |||

| 1/28 | 30 | 50 | 150 | 250 | 500 | 550 | |||

| 1/30 | 30 | 40 | 100 | 230 | 450 | 450 | |||

| 1/35 | 30 | 50 | 150 | 250 | 500 | 550 | |||

| 1/40 | 30 | 50 | 150 | 250 | 500 | 550 | |||

| 1/50 | 30 | 50 | 150 | 250 | 500 | 550 | |||

| 1/60 | 30 | 50 | 150 | 250 | 500 | 550 | |||

| 1/70 | 30 | 50 | 120 | 250 | 500 | 550 | |||

| 1/100 | 30 | 40 | 100 | 230 | 400 | 450 | |||

| Max. Output Torque | Nm | L1,L2 | 3-100 | 3 Times of Nominal Output Torque | |||||

| Input Speed | Rpm | L1,L2 | 3-100 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 |

| Standard Backlash | Arcmin | L1 | 3-10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 |

| L2 | 12-100 | ≤15 | ≤15 | ≤15 | ≤15 | ≤15 | ≤15 | ||

| Precision Backlash B2 | Arcmin | L1 | 3-10 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 |

| L2 | 12-100 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ||

| Precision Backlash B1 | Arcmin | L1 | 3-10 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 |

| L2 | 12-100 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ||

| Max. Radial Force | N | L1,L2 | 3-100 | 3250 | 3250 | 5850 | 9100 | 14300 | 19500 |

| Max. Axial Force | N | L1,L2 | 3-100 | 3250 | 3250 | 5850 | 9100 | 14300 | 19500 |

| Efficiency | % | L1 | 3-10 | 90% | |||||

| L2 | 12-100 | 85% | |||||||

| Weight | Kg | L1 | 3-10 | 2.9 | 3.8 | 10.5 | 15.5 | 31 | 37.5 |

| L2 | 12-100 | 3.3 | 4.3 | 11.2 | 17 | 35.5 | 42 | ||

| Operating Temperature | ℃ | L1,L2 | 3-100 | -10~80℃ | |||||

| Lubrication | L1,L2 | 3-100 | Synthetic Grease | ||||||

| Mounting Position | L1,L2 | 3-100 | Any direction | ||||||

| Noise Level | dB(A) | L1,L2 | 3-100 | ≤68 | ≤68 | ≤68 | ≤70 | ≤72 | ≤74 |

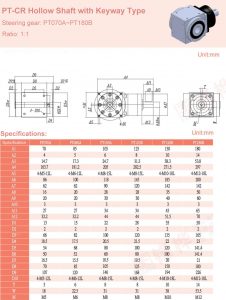

Dimensions