Features

PAW-2P is the right angle gearbox with two output shaft,consisted of high efficiency spiral bevel gears and planetary part with spur gears,so it is also called spiral bevel planetary gearbox.

The spiral bevel gears of PAW-2P right angle gearbox are made of high stretch SCM415 material and tooth hardness HRC60°~ HRC62°.Such excellent structure features PAW-2P with high strength and high rigidity and best for heavy loading change.

PAW-2P 90 degree right angle gearbox is with motor adapter on the input side,makes motor easily mount the gearbox.The planetary frame and 90 degree structure make the gearbox compact and perfectly applied to the transmission mechanism that need to change the motion direction with limited space.

PAW-2P right angle gearbox generates low heat and low noise when rotating.This allows a continuous high speed without sacrifice to performance and favored by a majority of users.

PAW-2P right angle gearbox have a variety of ratio adapt to different speed and torque requirements:

1-stage:3, 4 ,5, 6, 7, 10

2-stage:12, 15, 16, 20, 25, 28, 30, 35, 40, 50, 60, 70, 100

The 90 degree gearbox has a wide range of nominal torques 10Nm~1200Nm,suitable for different loads of the transmission system.

PAW-2P 90 degree right angle gearbox have three types of backlash:

Standard backlash: 10~15arcmin

Precision backlash(B2):5~8arcmin

Precision backlash(B1):3~5arcmin

Sizes available: PAW070A / PAW085A / PAW105A / PAW125A / PAW125B / PAW150A / PAW150B / PAW180A / PAW180B

Widely used in Printer, Belt Conveyors, Gantry Robot, Auto packing sealing machine, Packing machine (vertical pillow), Packing machine (horizontal pillow), Dispenser Robot, Loader robot and some other heavy load case.

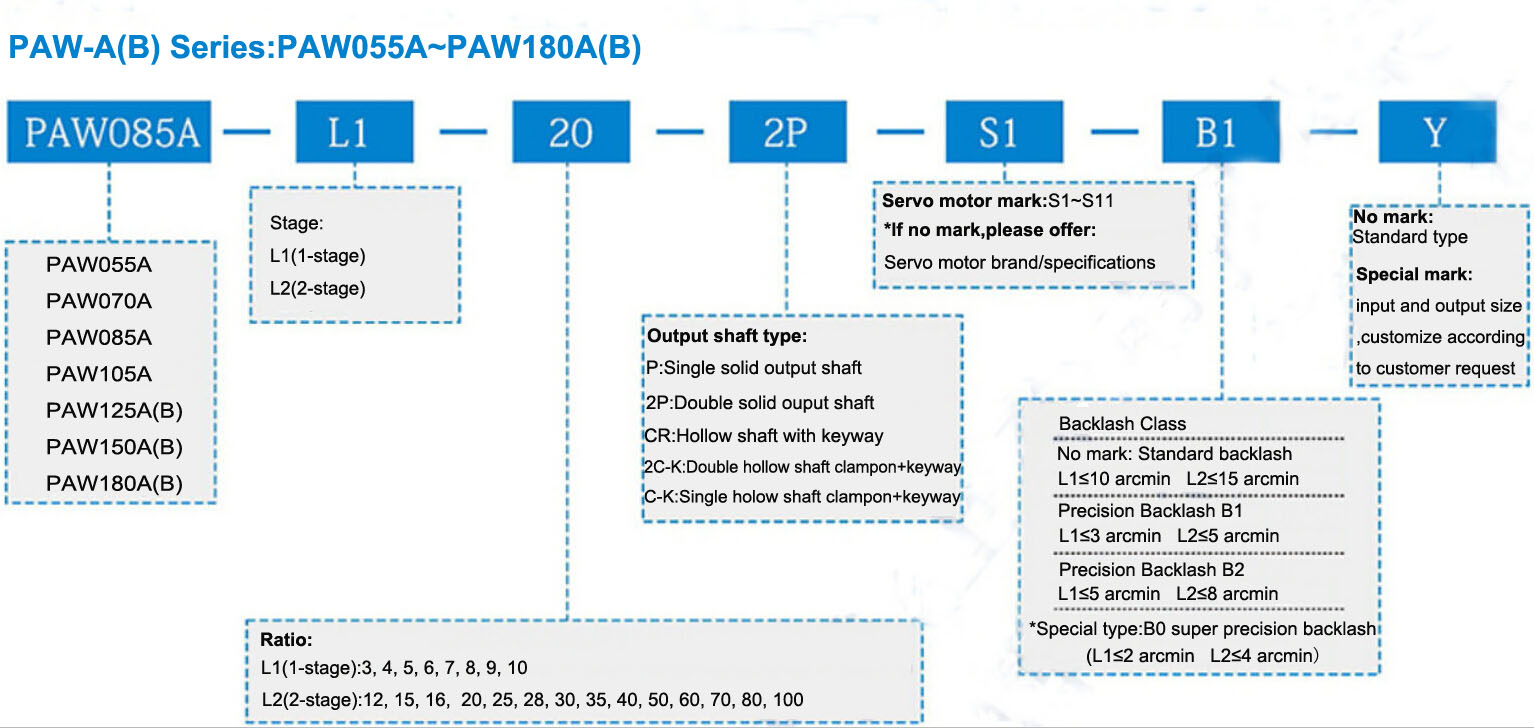

Model indication

Parameters

| Model No. | Unit | Stage | Ratio(i) | PAW055A | PAW070A | PAW085A | PAW105A | PAW125A | PAW125B | PAW150A | PAW150B | PAW180A | PAW180B |

| Rated OutputTorque | Nm | L1 | 1/3 | 10 | 30 | 40 | 100 | 230 | 100 | 400 | 230 | 900 | 450 |

| 1/4 | 15 | 30 | 50 | 150 | 250 | 160 | 500 | 330 | 1100 | 550 | |||

| 1/5 | 15 | 30 | 50 | 150 | 250 | 160 | 500 | 330 | 1200 | 550 | |||

| 1/6 | 14 | 30 | 42 | 120 | 230 | 160 | 500 | 290 | 1100 | 530 | |||

| 1/7 | 14 | 30 | 42 | 120 | 230 | 160 | 500 | 290 | 1100 | 530 | |||

| 1/10 | 10 | 30 | 40 | 100 | 230 | 100 | 400 | 230 | 900 | 450 | |||

| L2 | 1/12 | 10 | 30 | 40 | 100 | 230 | 100 | 400 | 230 | 900 | 450 | ||

| 1/15 | 10 | 30 | 40 | 100 | 230 | 100 | 400 | 230 | 900 | 450 | |||

| 1/16 | 15 | 30 | 50 | 150 | 250 | 160 | 500 | 330 | 1200 | 550 | |||

| 1/20 | 15 | 30 | 50 | 150 | 250 | 160 | 500 | 330 | 1200 | 550 | |||

| 1/25 | 15 | 30 | 50 | 150 | 250 | 160 | 500 | 330 | 1200 | 550 | |||

| 1/28 | 15 | 30 | 50 | 150 | 250 | 160 | 500 | 330 | 1100 | 550 | |||

| 1/30 | 10 | 30 | 40 | 100 | 230 | 100 | 450 | 330 | 900 | 450 | |||

| 1/35 | 15 | 30 | 50 | 150 | 250 | 160 | 500 | 330 | 1100 | 550 | |||

| 1/40 | 15 | 30 | 50 | 150 | 250 | 160 | 500 | 330 | 1100 | 550 | |||

| 1/50 | 15 | 30 | 50 | 150 | 250 | 160 | 500 | 330 | 1100 | 550 | |||

| 1/60 | 15 | 30 | 50 | 150 | 250 | 160 | 500 | 330 | 1100 | 550 | |||

| 1/70 | 12 | 30 | 50 | 120 | 250 | 160 | 500 | 290 | 1100 | 550 | |||

| 1/100 | 10 | 30 | 40 | 100 | 230 | 100 | 400 | 230 | 900 | 450 | |||

| Max. Output Torque | Nm | L1,L2 | 3-100 | 3 Times of Normal Output Torque | |||||||||

| Input Speed | Rpm | L1,L2 | 3-100 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 |

| Standard Backlash | Arcmin | L1 | 3-10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 |

| L2 | 12-100 | ≤15 | ≤15 | ≤15 | ≤15 | ≤15 | ≤15 | ≤15 | ≤15 | ≤15 | ≤15 | ||

| Precision Backlash B2 | Arcmin | L1 | 3-10 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 |

| L2 | 12-100 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ||

| Precision Backlash B1 | Arcmin | L1 | 3-10 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | |

| L2 | 12-100 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | |||

| Max. Radial Force | N | L1,L2 | 3-100 | 1100 | 3250 | 3250 | 5850 | 9100 | 9100 | 14300 | 14300 | 19500 | 19500 |

| Max. Axial Force | N | L1,L2 | 3-100 | 650 | 3250 | 3250 | 5850 | 9100 | 9100 | 14300 | 14300 | 19500 | 19500 |

| Efficiency | % | L1 | 3-10 | 90% | |||||||||

| L2 | 12-100 | 85% | |||||||||||

| Weight | Kg | L1 | 3-10 | 1.8 | 2.9 | 3.8 | 10.5 | 15.5 | 12.5 | 31 | 25.5 | 56.5 | 37.5 |

| L2 | 12-100 | 2.1 | 3.3 | 4.3 | 11.2 | 17 | 13.2 | 35.5 | 28.5 | 63.5 | 42 | ||

| Operating Temp. | ℃ | L1,L2 | 3-100 | (-10℃~+80℃) | |||||||||

| Lubrication | L1,L2 | 3-100 | COMPLEX HV2 | ||||||||||

| Mounting Position | L1,L2 | 3-100 | Any Direction | ||||||||||

| Noise Level | dB(A) | L1,L2 | 3-100 | ≤68 | ≤68 | ≤68 | ≤68 | ≤70 | ≤70 | ≤72 | ≤72 | ≤74 | ≤74 |

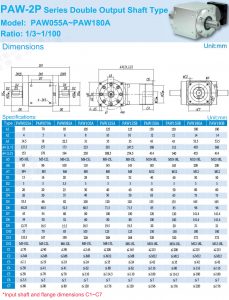

Dimensions

Input Size

Download

Real Pictures