Features

ZR series right angle gearbox input and output forms a angle of 90 degree, small volume and compact structure make mounting space saved. It has low backlash less than 10 sec,and mainly used in automation industry.

1.The right angle reducer is processed by advanced six axial precise machine, clamp once time and finish process at same time to ensure the beat precision.

Transmission gears are precise developed, running at low backlash and high precision.

Precise transmission, quiet, stable, smooth, procedure: To achieve the high quality requirements of precise transmission, low noise, high stiffness.

2.ZR planetary gearboxes Compact mechanical structure and small volume efficiently save the mounting space.

3.ZR precision planetary gearboxes have characteristics of high output torque and low backlash though it has small volume and light weight.

4.Please advise the flange and shaft size of your motor before order.

Model Selection

How to choose a correct model of ZR speed reducers

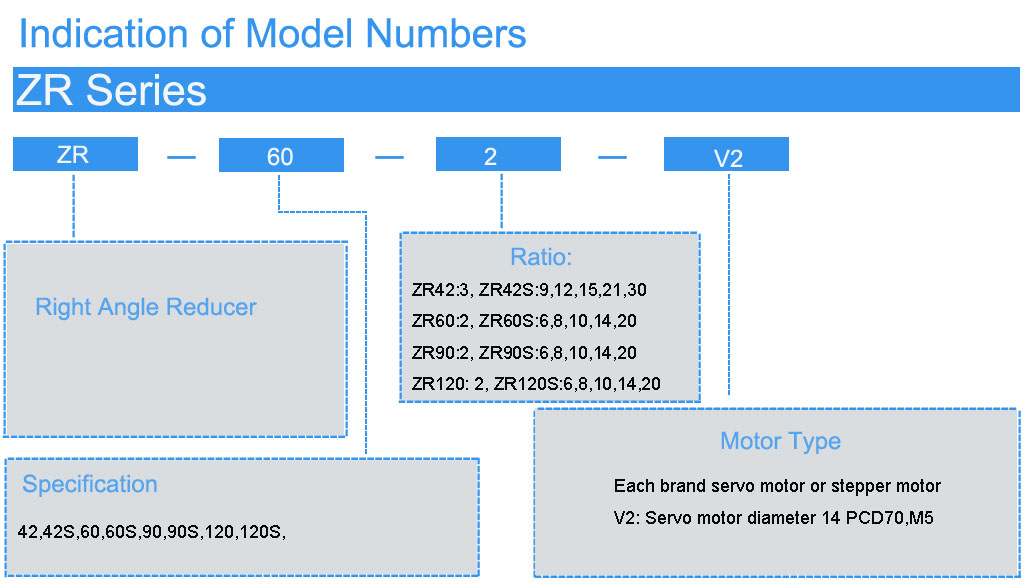

ZR-42 series--each brand 100W AC servo motor, each brand model 42 stepper motor

ZR-60 series-- each brand 200-400W AC servo motor, each brand model 60 stepper motor

ZR-90 series--each brand 750W AC servo motor, each brand model 86 stepper motor

ZK-120 series--each brand 1.1-1.5KW AC servo motor, each brand model 86 stepper motor

Parameters

| Model No. | Unit | Ratio | ZR42 | ZR42S | ZR60 | ZR60S | ZR90 | ZR90S | ZR120 | ZR120S |

| Rated Output Torque | Nm | 2 | / | / | 45 | / | 120 | / | 160 | / |

| 3 | 15 | / | / | / | / | / | / | / | ||

| 6 | / | / | / | 45 | 320 | / | 450 | |||

| 8 | / | / | / | 45 | / | 320 | / | 450 | ||

| 9 | / | 15 | / | / | / | / | / | / | ||

| 10 | / | / | / | 45 | / | 320 | / | 450 | ||

| 12 | / | 15 | / | / | / | / | / | / | ||

| 14 | / | / | / | 45 | / | 320 | / | 450 | ||

| 15 | / | 15 | / | / | / | / | / | / | ||

| 20 | / | / | / | 45 | / | 320 | / | 450 | ||

| 21 | / | 15 | / | / | / | / | / | / | ||

| 30 | / | 15 | / | / | / | / | / | / | ||

| Max. Output Torque | Nm | 2 | / | / | 120 | / | / | / | / | / |

| 3 | 40 | / | / | / | / | / | / | / | ||

| 6 | / | / | / | 120 | / | 320 | / | 450 | ||

| 8 | / | / | / | 120 | / | 320 | 450 | |||

| 9 | / | 40 | / | / | / | / | / | / | ||

| 10 | / | / | / | 120 | / | 320 | / | 450 | ||

| 12 | / | 40 | / | / | / | / | / | / | ||

| 14 | / | / | / | 120 | / | 320 | / | 450 | ||

| 15 | / | 40 | / | / | / | / | / | / | ||

| 20 | / | / | / | 120 | / | 320 | / | 450 | ||

| 21 | / | 40 | / | / | / | / | / | |||

| 30 | / | 40 | / | / | / | / | / | / | ||

| Rated Input Speed | Rpm | 2-30 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 | 2500 |

| Backlash | Min-arc | 2-30 | 0.5 | 2 | 0.5 | 2 | 0.5 | 2 | 0.5 | 2 |

| Weight | Kg | 2-30 | 0.5 | 0.9 | 1.2 | 2 | 3.6 | 6.5 | 8 | 15.5 |

| Servo Motor Power(AC) | W | 2-30 | 100 | 100 | 200~400 | 200~400 | 750 | 750 | 1100-1500 | 1100-1500 |

| Stepper Motor Type | 2-30 | 42 | 42 | 60 | 60 | 86 | 86 | 86 | 86 |

Application

ZR series planetary reducers are widely used in Printer, Belt Conveyer, Gantry Robot, Auto packing sealing machine, Packing machine ( vertical pillow), Packing machine ( horizontal pillow), Dispenser Robot, Loader robot etc.

Installation

(1)How to install the gearbox?

Step 1: Wipe off the anti-rust agent and grease on the motor shaft;

Step 2: Remove the rubber plug;

Step 3: Turn the input shaft until the cap screw is seen. Make sure the cap screw is loosened.

Step 4: Please place reducer vertically on a flat surface to make the surface of motor mounting upwards. Carefully insert motor shaft into the input shaft.( it should be inserted smoothly) Make sure the motor flange is perfectly fit to the reducer’s flange. Tighten the motor mounting bolt as per appointed fastening torque.

Step 5: Tightening the clamping bolt of input shaft with wrench according to the proper torque.

Step 6: Re-install the rubber plug. Finish the installation.

(2)How to store the reducer?

1)Keep the reducer in a clean and dry place.

2)If it will be stored outdoor or in a humid place, please put the reducer in a box and packed tightly with plastic bag to avoid the rain and external erosion. ( take measure of anti-condensation and anti-rust)

(3)Cautions for operation:

1)Please confirm the reducer model number confirm to the one you ordered when the reducer reach to you.

2)There is anti-rust agent on the reducer input and output shaft, please clean it before using.

3)Remove the rubber plug, wipe off the anti-rust agent.

4)The reducer was already filled with lubrication oil. You can use it right now.

5)When initial operation, please confirm the rotate direction of the output shaft, then increase the load little by little.

(4)Cautions during operation:

1)Overload is forbidden.

2)Input speed can not exceed the proper max. Speed.

3)Please stop and check the reducer if there are the following occurs:

Temperature rise suddenly

Abnormal big noise in a sudden

Speed became unstable suddenly

(5)Warranty instruction:

The following cost and damages are not included in our warranty:

1)Freight cost

2)If the Reducer connect with or insert in a unit, when we dismounting or mounting on the unit and other extra action, there will be a cost.( this is not contained in the warranty)

3)The indirect damage that user lost the appliance chance or business break off due to reducer breakdown.

4)Other derivative and accompanying damages.

Download

FAQ

1. What’s your delivery time?

Lead time: Normally 15-25 days after confirm your deposit. Products in stock will be delivered 3-5 days after your deposit.

2. What’s your MOQ?

MOQ is 1 PC

3. How long is your warranty?

Warranty: 1 year

4. Planetary gearbox can be customized?

Yes, please send your servo motor dimensions drawing.

5. Where is the gearbox manufactured?

Produced in Taiwan.

6. Your gearbox was ever shipped to which countries?

Our gearbox has been sold to various countries like Russia, Vietnam, Canada, Australia, UAE, Japan etc..

7. You are a factory or trading company?

We are factory, the manufacturer.