Features

CSG/CSF-2UH series harmonic drive units are available in ten sizes with gear ratios of 50, 80, 100, 120 and 160:1 offering repeatable peak torques from 23 to 3419 Nm.

The output bearing with high tilting rigidity enables the direct introduction of high payloads without further support and thus permits simple and space saving designs.

Standard servo motors can be attached in a compact manner. The harmonic drive gearboxes cover a wide torque range and feature long service life, confirmed by many years of successful service. Unit and motor together form a compact and lightweight system capable of quickly withstanding high loads. Due to the Units positioning accuracy, stable machine characteristics with short cycle times are guaranteed.

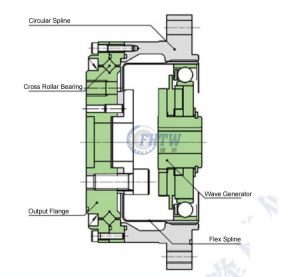

CSG&CSF combination harmonic gearboxes are mainly structured by component sets.The cross roller bearing inside the harmonic drive is with high precision and high rigidity,it is used for holding(main bearing) external loading.

CSG&CSF series combination harmonic drive gearbox can meet the request of high function, high speed, high load capacity, high density,subtle and accelerate the demand of the technical innovation, realize the rich product lineup, make the customer can according to their own situation to choose the best model.

Difference between CSG series and CSF series is that CSF series harmonic gearbox is with standard torque,while CSG series harmonic gearbox is with more higher torque and longer service time.

Features Of CSF&CSG Harmonic Drive Gearbox

*Compact design

*High torque capacity

*Zero backlash

*Excellent positioning accuracy and rotation accuracy

*Input and output are coaxial

*CSG harmonic reducer is used for high torque case,its torque is 30% higher than CSF reducer’s,also the life time is 43% longer(10000hours).

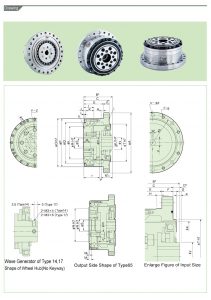

Structure of CSF&CSG Combination type

New Variable Options

CSG series harmonic drive gearbox: for high torque application

(1)Torque capacity is 30% higher than that of CSF series.

(2)Service life is 43% longer than which of CSF series. (10,000 hours)

(3)Reduction ratio 30:for high speed application

CSF-8,11series harmonic drive gearbox: miniaturization

(1)Such small CSF type harmonic gearboxes can achieve the advantages of IH gear shape in small size models

(2)Torque capacity of CSF harmonic drive is 30% larger than which of CS series harmonic gearbox

(3)The rigidity of CSF harmonic gearbox has been improved up 100% compared to traditional products.

(4)Service life has been improved a lot.

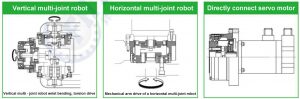

Application of CSG & CSF Series Harmonic Gearbox

FHTW CSG & CSF Series Harmonic drive gearbox is mainly used in industrial robot and different kinds of Machinery and equipment, such as robot twist bending,robot torsion drive and mechanical arm drive,metal working machines,communication equipment,crating and packaging machine,paper-making machines,optical machines,printing machine, medical equipment,bending machine,etc.

Model selection

CSG model indication

| Name | Model | Ratio | Type | Special type | ||||

| CSG | 14 | 50 | 80 | 100 | * | * | 2A=Component type

2UH=Combination type | SP=Shape,performance and other special typeBlank=Standard type |

| 17 | 50 | 80 | 100 | 120 | * | |||

| 20 | 50 | 80 | 100 | 120 | 160 | |||

| 25 | 50 | 80 | 100 | 120 | 160 | |||

| 32 | 50 | 80 | 100 | 120 | 160 | |||

| 40 | 50 | 80 | 100 | 120 | 160 | |||

| 45 | 50 | 80 | 100 | 120 | 160 | |||

| 50 | * | 80 | 100 | 120 | 160 | |||

| 58 | * | 80 | 100 | 120 | 160 | |||

| 65 | * | 80 | 100 | 120 | 160 | |||

Example:SHG(name) - 25(model) - 100(ratio) - 2UH(type) - (Special type)

CSF model indication

| Name | Model | Ratio | Type | Special type | |||||

| CSF | 14 | 30 | 50 | 80 | 100 | 120 | * | 2A=Component type 2UH=Combination type | SP=Shape,performance and other special typeBlank=Standard type |

| 17 | 30 | 50 | 80 | 100 | 120 | * | |||

| 20 | 30 | 50 | 80 | 100 | 120 | 160 | |||

| 25 | 30 | 50 | 80 | 100 | 120 | 160 | |||

| 32 | 30 | 50 | 80 | 100 | 120 | 160 | |||

| 40 | * | 50 | 80 | 100 | 120 | 160 | |||

| 45 | * | 50 | 80 | 100 | 120 | 160 | |||

| 50 | * | 50 | 80 | 100 | 120 | 160 | |||

| 58 | * | 50 | 80 | 100 | 120 | 160 | |||

| 65 | * | 50 | 80 | 100 | 120 | 160 | |||

Example:CSF(name) - 25(model) - 100(ratio) - 2UH(type) - (Special type)

Parameter

CSG parameters

| Model | Ratio | Rated torque of input speed 2000r/min | Max. torque of starting to stop | Max. torque of average load | Instant Max.torque | Max.input speed r/min | Average input speed r/min | Moment of inertia | |||||||

| Nm | kgfm | Nm | kgfm | Nm | kgfm | Nm | kgfm | Oil lubrication | Grease lubrication | Oil lubrication | Grease lubrication | I X10-4kgm² | J X10-5kgfms² | ||

| 14 | 50 | 7.0 | 0.7 | 23 | 2.3 | 9 | 0.9 | 46 | 4.7 | 14000 | 8500 | 6500 | 3500 | 0.033 | 0.034 |

| 80 | 10 | 1.0 | 30 | 3.1 | 14 | 1.4 | 61 | 6.2 | |||||||

| 100 | 10 | 1.0 | 36 | 3.7 | 14 | 1.4 | 70 | 7.2 | |||||||

| 17 | 50 | 21 | 2.1 | 44 | 4.5 | 34 | 3.4 | 91 | 9 | 10000 | 7300 | 6500 | 3500 | 0.079 | 0.081 |

| 80 | 29 | 2.9 | 56 | 5.7 | 35 | 3.6 | 113 | 12 | |||||||

| 100 | 31 | 3.2 | 70 | 7.2 | 51 | 5.2 | 143 | 15 | |||||||

| 120 | 31 | 3.2 | 70 | 7.2 | 51 | 5.2 | 112 | 11 | |||||||

| 20 | 50 | 33 | 3.3 | 73 | 7.4 | 44 | 4.5 | 127 | 13 | 10000 | 6500 | 6500 | 3500 | 0.193 | 0.197 |

| 80 | 44 | 4.5 | 96 | 9.8 | 61 | 6.2 | 165 | 17 | |||||||

| 100 | 52 | 5.3 | 107 | 10.9 | 64 | 6.5 | 191 | 20 | |||||||

| 120 | 52 | 5.3 | 113 | 11.5 | 64 | 6.5 | 191 | 20 | |||||||

| 160 | 52 | 5.3 | 120 | 12.2 | 64 | 6.5 | 191 | 20 | |||||||

| 25 | 50 | 51 | 5.2 | 127 | 13 | 72 | 7.3 | 242 | 25 | 7500 | 5600 | 5600 | 3500 | 0.413 | 0.421 |

| 80 | 82 | 8.4 | 178 | 18 | 113 | 12 | 332 | 34 | |||||||

| 100 | 87 | 8.9 | 204 | 21 | 140 | 14 | 369 | 38 | |||||||

| 120 | 87 | 8.9 | 217 | 22 | 140 | 14 | 395 | 40 | |||||||

| 160 | 87 | 8.9 | 229 | 23 | 140 | 14 | 408 | 42 | |||||||

| 32 | 50 | 99 | 10 | 281 | 29 | 140 | 14 | 497 | 51 | 7000 | 4800 | 4600 | 3500 | 1.69 | 1.72 |

| 80 | 153 | 16 | 395 | 40 | 217 | 22 | 738 | 75 | |||||||

| 100 | 178 | 18 | 433 | 44 | 281 | 29 | 841 | 86 | |||||||

| 120 | 178 | 18 | 459 | 47 | 281 | 29 | 892 | 91 | |||||||

| 160 | 178 | 18 | 484 | 49 | 281 | 29 | 892 | 91 | |||||||

| 40 | 50 | 178 | 18 | 523 | 53 | 255 | 26 | 892 | 91 | 5600 | 4000 | 3600 | 3000 | 4.5 | 4.59 |

| 80 | 268 | 27 | 675 | 69 | 369 | 38 | 1270 | 130 | |||||||

| 100 | 345 | 35 | 738 | 75 | 484 | 49 | 1400 | 143 | |||||||

| 120 | 382 | 39 | 802 | 82 | 586 | 60 | 1530 | 156 | |||||||

| 160 | 382 | 39 | 841 | 86 | 586 | 60 | 1530 | 156 | |||||||

| 45 | 50 | 229 | 23 | 650 | 66 | 345 | 35 | 1235 | 126 | 5000 | 3800 | 3300 | 3000 | 8.68 | 8.86 |

| 80 | 407 | 41 | 918 | 94 | 507 | 52 | 1651 | 168 | |||||||

| 100 | 459 | 47 | 982 | 100 | 650 | 66 | 2041 | 208 | |||||||

| 120 | 523 | 53 | 1070 | 109 | 806 | 82 | 2288 | 233 | |||||||

| 160 | 523 | 53 | 1147 | 117 | 819 | 84 | 2483 | 253 | |||||||

| 50 | 80 | 484 | 49 | 1223 | 125 | 675 | 69 | 2418 | 247 | 4500 | 3500 | 3000 | 2500 | 12.5 | 12.8 |

| 100 | 611 | 62 | 1274 | 130 | 866 | 88 | 2678 | 273 | |||||||

| 120 | 688 | 70 | 1404 | 143 | 1057 | 108 | 2678 | 273 | |||||||

| 160 | 688 | 70 | 1534 | 156 | 1096 | 112 | 3185 | 325 | |||||||

| 58 | 80 | 714 | 73 | 1924 | 196 | 1001 | 102 | 3185 | 325 | 4000 | 3000 | 2700 | 2200 | 27.3 | 27.9 |

| 100 | 905 | 92 | 2067 | 211 | 1378 | 141 | 4134 | 422 | |||||||

| 120 | 969 | 99 | 2236 | 228 | 1547 | 158 | 4329 | 441 | |||||||

| 160 | 969 | 99 | 2392 | 244 | 1573 | 160 | 4459 | 455 | |||||||

| 65 | 80 | 969 | 99 | 2743 | 280 | 1352 | 138 | 4836 | 493 | 3500 | 2800 | 2400 | 1900 | 46.8 | 47.1 |

| 100 | 1236 | 126 | 2990 | 305 | 1976 | 202 | 6175 | 630 | |||||||

| 120 | 1236 | 126 | 3263 | 333 | 2041 | 208 | 6175 | 630 | |||||||

| 160 | 1236 | 126 | 3419 | 349 | 2041 | 208 | 6175 | 630 | |||||||

Note:Moment of inertia I=1/4GD²

CSF parameters

| Model | Ratio | Rated torque of input speed 2000r/min | Max. torque of starting to stop | Max. torque of average load | Instant Max.torque | Max.input speed r/min | Average input speed r/min | Moment of inertia | |||||||

| Nm | kgfm | Nm | kgfm | Nm | kgfm | Nm | kgfm | Oil lubrication | Grease lubrication | Oil lubrication | Grease lubrication | I X10-4kgm² | J X10-5kgfms² | ||

| 14 | 30 | 4.0 | 0.41 | 9.0 | 0.92 | 6.8 | 0.69 | 17 | 1.7 | 14000 | 8500 | 6500 | 3500 | 0.033 | 0.034 |

| 50 | 5.4 | 0.55 | 18 | 1.8 | 6.9 | 0.7 | 35 | 3.6 | |||||||

| 80 | 7.8 | 0.8 | 23 | 2.4 | 11 | 1.1 | 47 | 4.8 | |||||||

| 100 | 7.8 | 0.8 | 28 | 2.9 | 11 | 1.1 | 54 | 5.5 | |||||||

| 17 | 30 | 8.8 | 0.9 | 16 | 1.6 | 12 | 1.2 | 30 | 3.1 | 10000 | 7300 | 6500 | 3500 | 0.079 | 0.081 |

| 50 | 16 | 1.6 | 34 | 3.5 | 26 | 2.6 | 70 | 7.1 | |||||||

| 80 | 22 | 2.2 | 43 | 4.4 | 27 | 2.7 | 87 | 8.9 | |||||||

| 100 | 24 | 2.4 | 54 | 5.5 | 39 | 4.0 | 108 | 11 | |||||||

| 120 | 24 | 2.4 | 54 | 5.5 | 39 | 4.0 | 86 | 8.8 | |||||||

| 20 | 30 | 15 | 1.5 | 27 | 2.8 | 20 | 2.0 | 50 | 5.1 | 10000 | 6500 | 6500 | 3500 | 0.193 | 0.197 |

| 50 | 25 | 2.5 | 56 | 5.7 | 34 | 3.5 | 98 | 10 | |||||||

| 80 | 34 | 3.5 | 74 | 7.5 | 47 | 4.8 | 127 | 13 | |||||||

| 100 | 40 | 4.1 | 82 | 8.4 | 49 | 5.0 | 147 | 15 | |||||||

| 120 | 40 | 4.1 | 87 | 8.9 | 49 | 5.0 | 147 | 15 | |||||||

| 160 | 40 | 4.1 | 92 | 9.4 | 49 | 5.0 | 147 | 15 | |||||||

| 25 | 30 | 27 | 2.8 | 50 | 5.1 | 38 | 3.9 | 95 | 9.7 | 7500 | 5600 | 5600 | 3500 | 0.413 | 0.421 |

| 50 | 39 | 4.0 | 98 | 10 | 55 | 5.6 | 186 | 19 | |||||||

| 80 | 63 | 6.4 | 137 | 14 | 87 | 8.9 | 255 | 26 | |||||||

| 100 | 67 | 6.8 | 157 | 16 | 108 | 11 | 284 | 29 | |||||||

| 120 | 67 | 6.8 | 167 | 17 | 108 | 11 | 304 | 31 | |||||||

| 160 | 67 | 6.8 | 176 | 18 | 108 | 11 | 314 | 32 | |||||||

| 32 | 30 | 54 | 5.5 | 100 | 10 | 75 | 7.7 | 200 | 20 | 7000 | 4800 | 4600 | 3500 | 1.69 | 1.72 |

| 50 | 76 | 7.8 | 216 | 22 | 108 | 11 | 382 | 39 | |||||||

| 80 | 118 | 12 | 304 | 31 | 167 | 17 | 568 | 58 | |||||||

| 100 | 137 | 14 | 333 | 34 | 216 | 22 | 647 | 66 | |||||||

| 120 | 137 | 14 | 353 | 36 | 216 | 22 | 686 | 70 | |||||||

| 160 | 137 | 14 | 372 | 38 | 216 | 22 | 686 | 70 | |||||||

| 40 | 50 | 137 | 14 | 402 | 41 | 196 | 20 | 686 | 70 | 5600 | 4000 | 3600 | 3000 | 4.5 | 4.59 |

| 80 | 206 | 21 | 519 | 53 | 284 | 29 | 980 | 100 | |||||||

| 100 | 265 | 27 | 568 | 58 | 372 | 38 | 1080 | 110 | |||||||

| 120 | 294 | 30 | 617 | 63 | 451 | 46 | 1180 | 120 | |||||||

| 160 | 294 | 30 | 647 | 66 | 451 | 46 | 1180 | 120 | |||||||

| 45 | 50 | 176 | 18 | 500 | 51 | 265 | 27 | 950 | 97 | 5000 | 3800 | 3300 | 3000 | 8.68 | 8.86 |

| 80 | 313 | 32 | 706 | 72 | 390 | 40 | 1270 | 130 | |||||||

| 100 | 353 | 36 | 755 | 77 | 500 | 51 | 1570 | 160 | |||||||

| 120 | 402 | 41 | 823 | 84 | 620 | 63 | 1760 | 180 | |||||||

| 160 | 402 | 41 | 882 | 90 | 630 | 64 | 1910 | 195 | |||||||

| 50 | 50 | 122 | 12 | 715 | 73 | 175 | 18 | 1430 | 146 | 4500 | 3500 | 3000 | 2500 | 12.5 | 12.8 |

| 80 | 372 | 38 | 941 | 96 | 519 | 53 | 1860 | 190 | |||||||

| 100 | 470 | 48 | 980 | 100 | 666 | 68 | 2060 | 210 | |||||||

| 120 | 529 | 54 | 1080 | 110 | 813 | 83 | 2060 | 210 | |||||||

| 160 | 529 | 54 | 1180 | 120 | 843 | 86 | 2450 | 250 | |||||||

| 58 | 50 | 176 | 18 | 1020 | 104 | 260 | 27 | 1960 | 200 | 4000 | 3000 | 2700 | 2200 | 27.3 | 27.9 |

| 80 | 549 | 56 | 1480 | 151 | 770 | 79 | 2450 | 250 | |||||||

| 100 | 696 | 71 | 1590 | 162 | 1060 | 108 | 3180 | 325 | |||||||

| 120 | 745 | 76 | 1720 | 176 | 1190 | 121 | 3330 | 340 | |||||||

| 160 | 745 | 76 | 1840 | 188 | 1210 | 123 | 3430 | 350 | |||||||

|

65 | 50 | 245 | 25 | 1420 | 145 | 360 | 37 | 2830 | 289 |

3500 |

2800 |

2400 |

1900 |

46.8 |

47.8 |

| 80 | 745 | 76 | 2110 | 215 | 1040 | 106 | 3720 | 380 | |||||||

| 100 | 951 | 97 | 2300 | 235 | 1520 | 155 | 4750 | 485 | |||||||

| 120 | 951 | 97 | 2510 | 256 | 1570 | 160 | 4750 | 485 | |||||||

| 160 | 951 | 97 | 2630 | 268 | 1570 | 160 | 4750 | 485 | |||||||

Note:Moment of inertia I=1/4GD²

Weight

Dimensions of CSG&CSF harmoic drive gearbox

Weight of each type

| Model | 14 | 17 | 20 | 25 | 32 | 40 | 45 | 50 | 58 | 65 |

| Weight(kg) | 0.52 | 0.68 | 0.98 | 1.5 | 3.2 | 5 | 7 | 8.9 | 14.6 | 20.9 |

Download

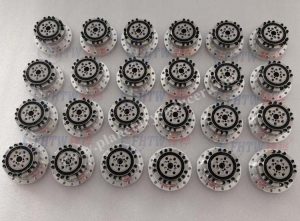

Real Pictures

Following silver color products are with high quality and high rigidity, the perfect option for robot application.

(Output Side)

(Input side)

Below black color products are economical type, widely used in different transmission machines.

(Output Side)

(Input Side)

(Attached with servo motor)