Features

AATM-2P spiral bevel gearbox is with two output shafts and one input flange.The planetary frame and 90 degree structure make the gearbox compact and perfectly applied to the transmission mechanism that need to change the motion direction with limited space.

AATM-2P right angle gearbox generates low heat and low noise when rotating.This allows a continuous high speed without sacrifice to performance and favored by a majority of users.

AATM-2P right angle gearboxes have the ratio 1:2~1:10.The 90 degree spiral bevel gearbox has a wide range of nominal torques 30Nm~4000Nm,suitable for different loads of the transmission system.

The right angle gearbox has five sizes available: AATM080AS / AATM110AS / AATM135AS / AATM165AS / AATM200BS

Appilcation

AATM-2P right angle planetary gearbox is suitable for semiconductor equipment, LCD rotating, PCB equipment, printing presses, AGV, Printer, Belt Conveyors, Gantry Robot, Auto packing sealing machine, Packing machine ( vertical pillow), Packing machine ( horizontal pillow), Dispenser Robot, Loader robot and some other heavy load case.

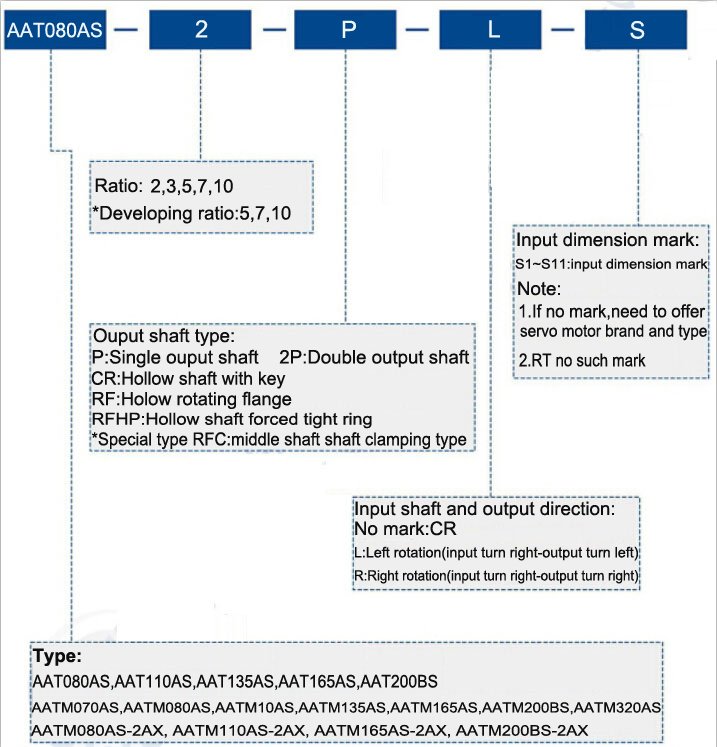

Model indication

Parameters

| Model No. | Stage | Ratio(i) | AATM080AS | AATM110AS | AATM135AS | AATM165AS | AATM200BS |

| Rated Output Torque(Nm) | L1 | 2, 3, 5, 10 | 80 | 250 | 450 | 800 | * |

| 6 | 80 | 200 | 400 | 700 | 1000 | ||

| 8 | 85 | 250 | 450 | 800 | 1100 | ||

| 10 | 85 | 250 | 450 | 800 | 1100 | ||

| Max. Output Torque(Nm) | L1,L2 | 3~100 | 2.5 Times of Normal Output Torque | ||||

| Input Speed(rpm) | L1,L2 | 3~100 | 3000 | 3000 | 3000 | 3000 | 3000 |

| Standard Back-lash (arc-min) | L1 | 3~10 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 |

| L2 | 12~100 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | |

| Precision Backlash B2(arc-min) | L1 | 3~10 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 |

| L2 | 12~100 | ≤4 | ≤4 | ≤4 | ≤4 | ≤4 | |

| Precision BacklashB1(arc-min) | L1 | 3~10 | ≤2 | ≤2 | ≤2 | ≤2 | ≤2 |

| L2 | 12~100 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | |

| Precision Backlash B0(arc-min) | L1 | 3~10 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

| L2 | 12~100 | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 | |

| Max. Radial Force(N) | L1,L2 | 3~100 | 3900 | 5500 | 9800 | 16500 | 24100 |

| Max. Axial Force(N) | L1,L2 | 3~100 | 3900 | 5500 | 9800 | 16500 | 24100 |

| Efficiency(%) | L1 | 3~10 | 90% | ||||

| L2 | 12~100 | 85% | |||||

| Weight(kg) | L1 | 3~10 | 7.8 | 4.3 | 20.8 | 35.5 | 40.5 |

| L2 | 12~100 | 9.2 | 6.3 | 24.3 | 40.5 | 48.5 | |

| Operating Temp. | L1,L2 | 3~100 | -10℃~+80℃ | ||||

| Lubrication | L1,L2 | 3~100 | COMPLEX HV2 | ||||

| Mounting Position | L1,L2 | 3~100 | Any Direction | ||||

| Noise Level (db) | L1,L2 | 3~100 | ≤68 | ≤68 | ≤68 | ≤70 | ≤72 |

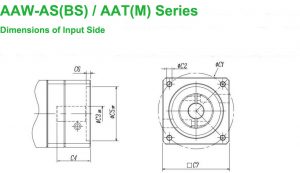

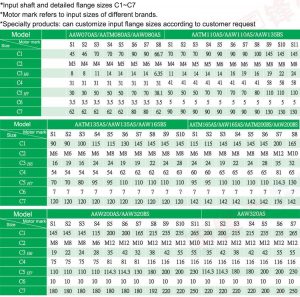

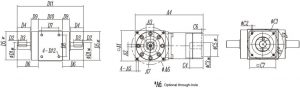

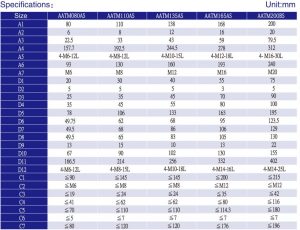

Dimension

Input Sizes