Features

NMRV worm gearbox has high practicalbility, blends domestic and abroad advanced technology. This gearbox can match with the common motor, stepless speed variator and flanged electromagnetic clutch brake and no need couplers. Suitable for all-directional mounting, high output torque and stable working.

1.Made of high quality aluminum alloy, light weight, non-rusting.

2.High output torque

3.Stable transmission, low noise, suitable to continuously work in dreadful condition for long time.

4.High efficiency of heat radiation

5.Beauty and durable, small volume.

6.Suitable for omnibearing installation.

Details

Main material

1.Housing: Aluminum, Alloy ( frame size from 025-090), Cast Iron ( Frame size from 110-150)

2.Worm: 20Cr. Carburizing and quenching treatment, hardness of gear surface is 56-62HRC, keep the thickness of carburized layer be 0.3-0.5m after accurate grinding.

3.Worm Gear: Wearable tin-bronze

Surface coating

Aluminum alloy housing

1.Do pellet blasting treatment first, then processed by special antiseptic to keep silver metal feeling. Also resist the corrosion of organic solvents like petrol, xylene etc.

2.Spray RAL5010 blue or silver coating after phosphating.

3.Cast Iron Housing: Painting red anti-rust paint first, then spray RAL5010 blue coating.

Model selection

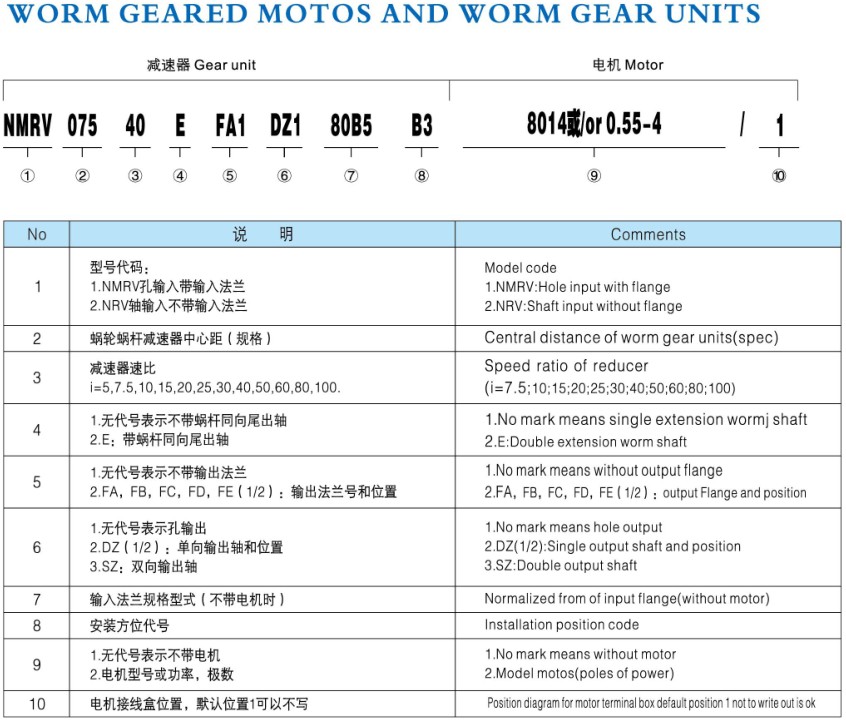

1.Types: NMRV worm gearbox has input types of hole, shaft and extended worm shaft; Output types of hole, single shaft and double shaft.

2.Central distance of worm gear units: we have nmrv030, nmrv040, nmrv050, nmrv063, nmrv075, nmrv90,nmrv110, nmrv130, nmrv150

3.Ratio: select a ratio closed to your desire to get the closest output speed.

4.Specification of input flange ( when gearbox is without motor)

5.Requirement for gearbox mounting position and terminal box position.

Application

Various industrial production lines, coveying machinery, food machinery, medical machinery, printing machinery, office facility, instrument, automatic mahjong machine

FAQ

1.Lead time: Normally 10-15 days after confirm your deposit.

2.MOQ is 1 PC

3.Warranty: 1 year

4.The gearbox can be customized?

Yes, please advise your technical requirement..

5.Where is the gear motor manufactured?

Produced in China Mainland.

6.Your gearbox was ever shipped to which countries?

Our gearbox has been sold to various countries like Russia, Vietnam, Canada, Australia, UAE, Japan etc..

operation

Cautions for installing reducer:

1.Please check if the rotated direction of output shaft is correct before assemble the reducer with mechanical equipment.

2.Before the reducer is assembled with the original motor and equipment, size deviation of each shaft diameter, bore diameter, key and key slot should be inspected to avoid affecting performance of reducer due to tight or loose assembly.

3.The reducer must be tightly mounted on the mechanical equipment to prevent from looseness and vibration.

4.Please avoid making the reducer exposed under burning sun and bad condition.

5.If the reducer have been stored for 4-6 months, please check if the oil seal is soaked by lubrication oil. Maybe the oil seal lip stick to the shaft even it lose elasticity. Since the proper elasticity is a essential working condition of oil seal, so change the oil seal.

6.All the rubber parts and air vent must not be stained with paint.

7.The mating part of shaft should be coated with lubrication oil to avoid struck or oxidation when matching with the reducer hollow shaft.

8.Please inspect the oil level when use the reducer.

9.Do not start the reducer with full load when use a new reducer, please increase the load gradually.

10.When use reducer which motor can direct connect with, if the motor weight is higher, a supporting unit should be set up.

11.Please make sure the motor fan is under a good ventilated condition in case the radiation efficiency is influenced.

12.The standard working temperature of reducer is range from -5℃ to 40℃, please get contact with our technical staff if your working temperature is beyond the range.