Features

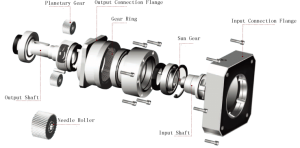

PAB series is one of the most popular planetary gearboxes of FHTW. It has been developed specifically for delivering the maximum performance at high speeds. Its helical teeth provide homogeneous synchronism and quiet running noise. PAB planetary gearbox is with high precision(P0 and P1 backlash), and the backlash can be to 1 arcmin. PAB planetary reduction planet gear is supported by both ends of the full needle roller bearing, which enhances the torsion stiffness.Output shaft of PAB planetary gearbox reducer is supported by two taper rollers on both ends to achieve greater bearing capacity.

PAB inline precision planetary gearbox is a direct connection type with square body,shortening the positioning time of starting and stopping.It is with shaft output.The Self aligning input flange makes PAB planetary gearbox connect fast with any motor output shaft.

With the compact structure,PAB helical gear speed reducer is with lower backlash and high precision than other similar models,it is with long service time.FHTW helical gear precision gearbox can be dimension customized according to different types of motors.

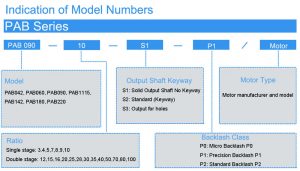

PAB planetary gearbox reducer has a large range of speed ratio,it has single stage and double stage.

Single stage ratio:3,4,5,6,7,8,9,10 ;

Double stage:12,15,20,25,30,35,40,45,50,60,70,80,90,100.

As one of most popular helical precision planetary gearbox,PAB series have the below features

(1) Lowest backlash of 0-3 arcmin.

(2) High torque and high dynamic.

(3) High cost performance.

(4) Applicable for all servo motor and stepper motor.

(5) Improve the rigidity and increase the motor rotor inertia.

(6) Shorten the positioning time of starting and stopping

(7) Miniaturization of motor power. At the same time, improve the stability of inertia load and reduce the vibration.

(8) The surface of the gear box is treated with electroless Nickel, and the connection plate is treated with blue anode to improve the tolerance and corrosion resistance of the environment.

(9) The structure that planet carrier and output shaft is integrated guarantee the maximum torque stiffness and stability.

(10) Electroless Nickel treatment was adopted on the gearbox surface, blue anodizing treatment was employed to the connection plate to enhance the tolerance and corrosion resistance of environment.

(11) High efficiency of 95%

(12) Lift-time lubrication.

Application

FHTW PAB High Precision Planetary Gearboxes are widely used in different kinds of transmission fields,such as Belt Conveyer, Gantry Robot,CNC machines,pipe bending machine,aviation industry, spaceflight, ship, radar, submarine, food machinery, medical machinery, composite materials. Equipment, precision testing instruments, data communication system, robot, mechanical arm,cutting and welding equipment, laser system, textile machinery, printing and dyeing machinery, Packing machine, printing machinery, testing machines, stamping technology, plastic machinery, glass machinery, lifting machinery, metallurgical machinery, engineering machinery and University Scientific Research Institute,Dispenser Robot, Loader robot etc.

Model Selection

PAB series precision planetary gearbox can connect to any brand of servo motors and stepper motors.

PAB single stage reduction ratio:3, 4, 5, 6, 7, 8, 9, 10

PAB double stage reduction ratio:12,15,20,25,30,35,40,45,50,60,70,80,90,100

How to choose a correct PAB model?

(1)Check your motor drawing,offer the below dimensions:

φS:shaft diameter

LB:motor convex circle diameter

φLA:motor flange PCD

LS:shaft length

LE:motor convex circle thickness

φLZ:motor mounting hole size

Then compare these dimensions to our gearbox dimensions(refer to our catalogue)you can probably know the frame size of our gearbox.

(2)What’s the ratio or output speed you need?Check if the gearbox output torque>motor torque*ratio

Ratio i=Input speed(RPM)/gearbox output speed(RPM)

Motor torque(N.m)=9550*motor power(KW)/motor speed(RPM)

(3)Make sure the precision(backlash)you need,then you can know which type of gearbox you need.

(4)If you don’t have the information above,please send us the servo motor dimension drawing for model selection or advise the specific servo motor model number,then we are pleasure to help you choose a suitable model.

Parameters

Technical parameters of PAB precision gearbox

| Model No. | Unit | Stage | Ratio | PAB042 | PAB060 | PAB090 | PAB115 | PAB142 | PAB180 | PAB220 |

| Rated Output Torque | Nm | 1 | 3 | 19 | 56 | 148 | 280 | 520 | 1020 | 1550 |

| 4 | 20 | 55 | 160 | 330 | 580 | 1280 | 2160 | |||

| 5 | 21 | 58 | 159 | 330 | 580 | 1250 | 2100 | |||

| 6 | 16 | 48 | 120 | 240 | 410 | 980 | 1350 | |||

| 7 | 19 | 50 | 148 | 300 | 530 | 1030 | 1580 | |||

| 8 | 13 | 45 | 130 | 230 | 450 | 880 | 1260 | |||

| 9 | 12 | 40 | 100 | 220 | 410 | 880 | 1450 | |||

| 10 | 15 | 46 | 125 | 260 | 475 | 950 | 1530 | |||

| 2 | 12 | 18 | 52 | 155 | 300 | 530 | 1100 | 1750 | ||

| 15 | 18 | 53 | 150 | 280 | 550 | 1050 | 1650 | |||

| 16 | 20 | 53 | 158 | 320 | 580 | 1200 | 2050 | |||

| 20 | 20 | 52 | 155 | 320 | 580 | 1200 | 2050 | |||

| 25 | 19 | 52 | 158 | 320 | 580 | 1200 | 2000 | |||

| 28 | 19 | 50 | 150 | 300 | 550 | 1100 | 1850 | |||

| 30 | 18 | 49 | 145 | 390 | 500 | 1050 | 1600 | |||

| 35 | 17 | 48 | 155 | 290 | 500 | 1020 | 1500 | |||

| 40 | 18 | 48 | 150 | 290 | 530 | 1100 | 1350 | |||

| 50 | 18 | 50 | 145 | 290 | 530 | 1000 | 1300 | |||

| 70 | 16 | 50 | 140 | 280 | 490 | 1000 | 1200 | |||

| 80 | 10 | 43 | 110 | 230 | 410 | 960 | 980 | |||

| 100 | 10 | 43 | 120 | 260 | 450 | 950 | 1100 | |||

| Max. Output Torque | Nm | 1,2 | 3-100 | 3 Times of Normal Output Torque | ||||||

| Rated Input Speed | Rpm | 1,2 | 3-100 | 4000 | 4000 | 4000 | 3500 | 3000 | 2000 | 2000 |

| Max. Input Speed | Rpm | 1,2 | 3-100 | 6000 | 6000 | 6000 | 5500 | 4500 | 4500 | 4000 |

| Micro Backlash P0 | Arcmin | 1 | 3-10 | / | / | ≤1 | ≤1 | ≤1 | ≤1 | ≤1 |

| 2 | 12-100 | / | / | / | ≤3 | ≤3 | ≤3 | ≤3 | ||

| Precision Backlash P1 | Arcmin | 1 | 3-10 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 |

| 2 | 12-100 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ||

| Standard Backlash P2 | Arcmin | 1 | 3-10 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 | ≤7 |

| 2 | 12-100 | ≤9 | ≤9 | ≤9 | ≤9 | ≤9 | ≤9 | ≤9 | ||

| Torsional Rigidity | Nm/arcmin | 1,2 | 3-100 | 3 | 7 | 12 | 25 | 50 | 140 | 210 |

| Max. Radial Force | N | 1,2 | 3-100 | 780 | 1300 | 3200 | 6750 | 9400 | 14500 | 50000 |

| Max. Axial Force | N | 1,2 | 3-100 | 330 | 700 | 1580 | 3300 | 4700 | 7200 | 28000 |

| Service Life | Hr | 1,2 | 3-100 | 21000hrs | ||||||

| Efficiency | % | 1 | 3-10 | ≥97% | ||||||

| 2 | 12-100 | ≥94% | ||||||||

| Weight | Kg | 1 | 3-10 | 0.5 | 1.3 | 3.7 | 7.8 | 15 | 29 | 52 |

| 2 | 12-100 | 0.8 | 1.48 | 4.1 | 9.6 | 18.9 | 33 | 66 | ||

| Operating Temperature | ℃ | 1,2 | 3-100 | (-15℃~+90℃) | ||||||

| Lubrication | 1,2 | 3-100 | Synthetic Grease | |||||||

| Protection Class | 1,2 | 3-100 | IP65 | |||||||

| Mounting Position | 1,2 | 3-100 | Any Direction | |||||||

| Noise Level | dB(A) | 1,2 | 3-100 | ≤63 | ≤63 | ≤63 | ≤65 | ≤65 | ≤70 | ≤70 |

Moment of Inertia

| Model No. | Unit | Stage | Ratio | PAB042 | PAB060 | PAB090 | PAB115 | PAB142 | PAB180 | PAB220 |

| Moment of Inertia | kg.cm2 | 1 | 3 | 0.03 | 0.16 | 0.61 | 3.25 | 9.21 | 28.98 | 69.61 |

| 4 | 0.03 | 0.14 | 0.48 | 2.74 | 7.54 | 23.67 | 54.37 | |||

| 5 | 0.03 | 0.13 | 0.47 | 2.71 | 7.42 | 23.29 | 53.27 | |||

| 6 | 0.03 | 0.13 | 0.45 | 2.65 | 7.25 | 22.75 | 51.72 | |||

| 7 | 0.03 | 0.13 | 0.45 | 2.62 | 7.14 | 22.48 | 50.97 | |||

| 8 | 0.03 | 0.13 | 0.44 | 2.58 | 7.07 | 22.59 | 50.84 | |||

| 9 | 0.03 | 0.13 | 0.44 | 2.57 | 7.04 | 22.53 | 50.63 | |||

| 10 | 0.03 | 0.13 | 0.44 | 2.57 | 7.03 | 22.51 | 50.56 | |||

| 2 | 12-40 | 0.03 | 0.03 | 0.13 | 0.47 | 2.71 | 7.42 | 23.29 | ||

| 50-100 | 0.03 | 0.03 | 0.13 | 0.44 | 2.57 | 7.03 | 22.51 |

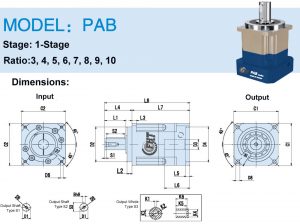

Dimensions

(1) Single stage(Ratio:3,4, 5, 6,7, 8,9,10)

Unit:mm

| Size | PAB042-L1 | PAB060-L1 | PAB090-L1 | PAB115-L1 | PAB142-L1 | PAB180-L1 | PAB220-L1 |

| D1 | Φ13 | Φ16 | Φ22 | Φ32 | Φ40 | Φ55 | Φ75 |

| D2 | Φ35 | Φ50 | Φ80 | Φ110 | Φ130 | Φ160 | Φ180 |

| D3 | Φ8(≤11) | Φ14(≤14) | Φ19(≤24) | Φ24(≤32) | Φ35(≤42) | Φ38(≤50) | Φ55(≤55) |

| D4 | Φ30(30-50) | Φ50(30-70) | Φ70(50-110) | Φ110(50-130) | Φ114.3(95-180) | Φ180(95-180) | Φ215(180-255) |

| D5 | Φ50 | Φ70 | Φ100 | Φ130 | Φ165 | Φ215 | Φ250 |

| D6 | 4-Φ3.4 | 4-Φ5.5 | 4-Φ6.6 | 4-Φ9 | 4-Φ11 | 4-Φ13 | 4-Φ17 |

| D7 | Φ46(22-70) | Φ70(45-90) | Φ90(70-145) | Φ145(70-145) | Φ200(90-215) | Φ200(90-300) | Φ235(200-300) |

| D8 | (4-M3X8L) | (4-M5X10L) | (4-M6X12L) | (4-M8X25L) | (4-M12X30L) | (4-M12X30L) | (4-M12X30L) |

| D9 | M4X0.7P | M5X0.8P | M8X1.25P | M12X1.75P | M16X2.0P | M20X2.5P | M20X2.5P |

| L1 | 19 | 28.5 | 36.5 | 51 | 79 | 82 | 105 |

| L2 | 5.5 | 7 | 10 | 12 | 15 | 20 | 30 |

| L3 | 4 | 6 | 8 | 10 | 12 | 15 | 20 |

| L4 | 26 | 37 | 48 | 65 | 97 | 105 | 138 |

| L5 | (4) | (5) | (7) | (11) | (7) | (7) | (12.5) |

| L6 | 30 | 34 | 45 | 65 | 67.5 | 85 | 105 |

| L7 | (65.5) | (78) | (99) | (135) | (150) | (182) | (226) |

| L8 | (91.5) | (115) | (147) | (200) | (247) | (287) | (365) |

| C1 | □42 | □60 | □90 | □115 | □142 | □180 | □220 |

| C2 | (□42) | (□60) | (□90) | (□130) | (□142) | (□180) | (□220) |

| S1 | 2 | 2 | 3 | 5 | 5 | 5 | 7 |

| S2 | 16 | 25 | 32 | 40 | 65 | 70 | 90 |

| S3 | 15 | 18 | 24.5 | 35 | 43 | 59 | 79 |

| B | 5 | 5 | 6 | 10 | 12 | 16 | 20 |

| K1 | 3 | 4 | 6 | 8 | 10 | 14 | 16 |

| K2 | Φ8 | Φ11 | Φ22 | Φ28 | Φ38 | Φ50 | Φ60 |

| K3 | 9.2 | 12.7 | 25 | 31.3 | 42 | 53.8 | 64.4 |

| K4 | Φ13 | Φ16 | Φ32 | Φ38 | Φ48 | Φ60 | Φ72 |

| K5 | 15 | 15 | 20 | 27 | 35 | 43 | 60 |

| K6 | 18 | 18 | 24 | 32 | 40 | 50 | 65 |

Note 1:Inside of ()is the optional range of sizes,outside of ()is the standard sizes.

Note 2:The reducer output shaft size and length can be customized for customers.

Note 3:Input sizes can be subject to changed according to kinds of servo motor or stepper motor size.

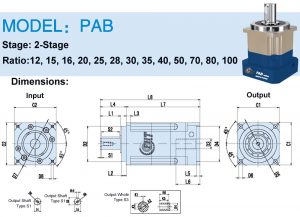

(2) Double stage(Ratio: 12,15,16,20,25,28,30,35,40,50,70,80,100)

unit:mm

| Size | PAB042-L2 | PAB060-L2 | PAB090-L2 | PAB115-L2 | PAB142-L2 | PAB180-L2 | PAB220-L2 |

| D1 | Φ13 | Φ16 | Φ22 | Φ32 | Φ40 | Φ55 | Φ75 |

| D2 | Φ35 | Φ50 | Φ80 | Φ110 | Φ130 | Φ160 | Φ180 |

| D3 | Φ8(≤11) | Φ14(≤14) | Φ19(≤24) | Φ24(≤32) | Φ35(≤42) | Φ38(≤50) | Φ55(≤55) |

| D4 | Φ30(30-50) | Φ50(30-70) | Φ70(50-110) | Φ110(50-130) | Φ114.3(95-180) | Φ180(95-180) | Φ215(180-255) |

| D5 | Φ50 | Φ70 | Φ100 | Φ130 | Φ165 | Φ215 | Φ250 |

| D6 | 4-Φ3.4 | 4-Φ5.5 | 4-Φ6.6 | 4-Φ9 | 4-Φ11 | 4-Φ13 | 4-Φ17 |

| D7 | Φ46(22-70) | Φ70(45-90) | Φ90(70-145) | Φ145(70-145) | Φ200(90-215) | Φ200(90-300) | Φ235(200-300) |

| D8 | (4-M3X8L) | (4-M5X10L) | (4-M6X12L) | (4-M8X25L) | (4-M12X30L) | (4-M12X30L) | (4-M12X30L) |

| D9 | M4X0.7P | M5X0.8P | M8X1.25P | M12X1.75P | M16X2.0P | M20X2.5P | M20X2.5P |

| L1 | 19 | 28.5 | 36.5 | 51 | 79 | 82 | 105 |

| L2 | 5.5 | 7 | 10 | 12 | 15 | 20 | 30 |

| L3 | 4 | 6 | 8 | 10 | 12 | 15 | 20 |

| L4 | 26 | 37 | 48 | 65 | 97 | 105 | 138 |

| L5 | (4) | (5) | (7) | (11) | (7) | (7) | (12.5) |

| L6 | 25 | 34 | 45 | 65 | 67.5 | 85 | 105 |

| L7 | (93.0) | (117) | (144) | (161) | (196) | (232) | (277) |

| L8 | (114.0) | (154) | (192) | (226) | (293) | (337) | (415) |

| C1 | □42 | □60 | □90 | □115 | □142 | □180 | □220 |

| C2 | (□42) | (□60) | (□90) | (□130) | (□142) | (□180) | (□220) |

| S1 | 2 | 2 | 3 | 5 | 5 | 5 | 7 |

| S2 | 16 | 25 | 32 | 40 | 65 | 70 | 90 |

| S3 | 15 | 18 | 24.5 | 35 | 43 | 59 | 79 |

| B | 5 | 5 | 6 | 10 | 12 | 16 | 20 |

| K1 | 3 | 4 | 6 | 8 | 10 | 14 | 16 |

| K2 | Φ8 | Φ11 | Φ22 | Φ28 | Φ38 | Φ50 | Φ60 |

| K3 | 9.2 | 12.7 | 25 | 31.3 | 42 | 53.8 | 64.4 |

| K4 | Φ13 | Φ16 | Φ32 | Φ38 | Φ48 | Φ60 | Φ72 |

| K5 | 15 | 15 | 20 | 27 | 35 | 43 | 60 |

| K6 | 18 | 18 | 24 | 32 | 40 | 50 | 65 |

Note 1:Inside of ()is the optional range of sizes,outside of ()is the standard sizes.

Note 2:The reducer output shaft size and length can be customized for customers.

Note 3:Input sizes can be subject to changed according to kinds of servo motor or stepper motor size.

Download

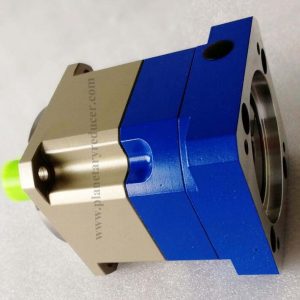

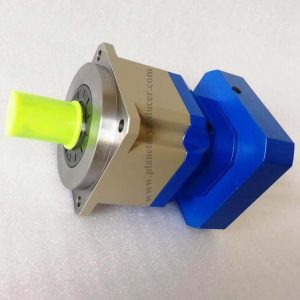

Real Pictures

Blue&Gold Color of Single Stage Ratio

Black&Gold Color of Single Stage Ratio

Double Stage Ratio

PAB products in customer factory