Features

PAW-P is the right angle spiral bevel gearbox with one output shaft on left or right.Input side of PAW-P right angle servo gearbox is with motor adapter,which makes the mounted operation more easy without any extra installation accessories.

As a 90 degree gearbox,PAW-P series is the ideal option for the applicable transmission with limited space or needs to change the motion direction.PAW-P right angle 90 degree gearbox consists of stainless steel housing,spiral bevel gears and planetary unit with spur gears,so it is also called spiral bevel planetary gearbox.

PAW-P right angle gearbox have a variety of ratio from 3:1 to 100:1.The 90 degree gearbox has a wide range of nominal torques 10Nm~1200Nm,suitable for different loads of the transmission system.

PAW-P has a broad range of sizes based on the below models : PAW070A-P / PAW085A-P / PAW105A-P / PAW125A-P / PAW125B-P / PAW150A-P / PAW150B-P / PAW180A-P / PAW180B-P

PAW-P 90 degree right angle gearbox is widely used in robot industry,pipe bending machine,stamping equipment,pulley,belt drives,printing machine,CNC machine,etc.

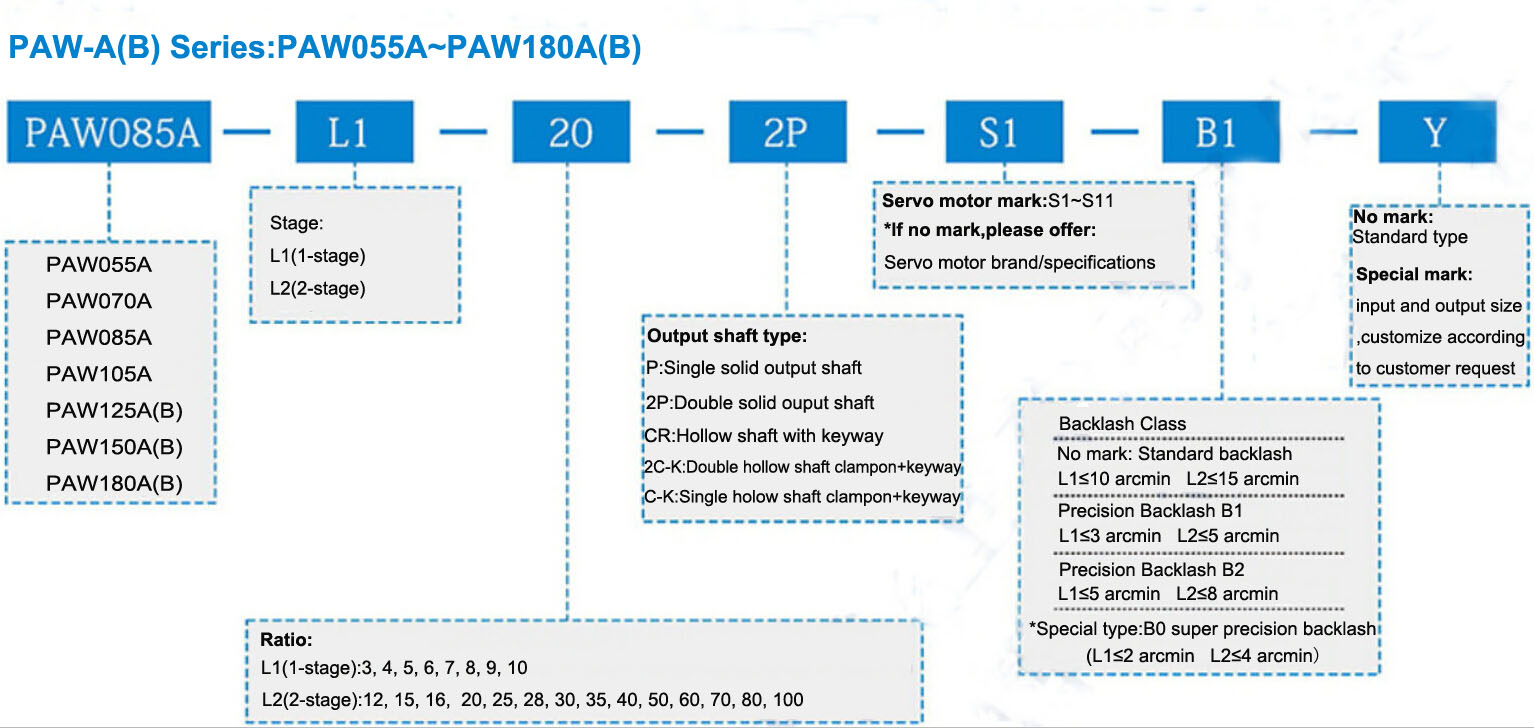

Model Indication

If you don't know how to choose a suitable model of PAW-P 90 degree spiral bevel gearbox,please offer the motor details,such as motor power,torque,dimensions and the reduction ratio or output speed that you need.Or you can directly contact us online,we are willing to guide you to select the model step by step.

Parameters

| Model No. | Unit | Stage | Ratio(i) | PAW055A | PAW070A | PAW085A | PAW105A | PAW125A | PAW125B | PAW150A | PAW150B | PAW180A | PAW180B |

| Rated Output Torque | Nm | L1 | 1/3 | 10 | 30 | 40 | 100 | 230 | 100 | 400 | 230 | 900 | 450 |

| 1/4 | 15 | 30 | 50 | 150 | 250 | 160 | 500 | 330 | 1100 | 550 | |||

| 1/5 | 15 | 30 | 50 | 150 | 250 | 160 | 500 | 330 | 1200 | 550 | |||

| 1/6 | 14 | 30 | 42 | 120 | 230 | 160 | 500 | 290 | 1100 | 530 | |||

| 1/7 | 14 | 30 | 42 | 120 | 230 | 160 | 500 | 290 | 1100 | 530 | |||

| 1/10 | 10 | 30 | 40 | 100 | 230 | 100 | 400 | 230 | 900 | 450 | |||

| L2 | 1/12 | 10 | 30 | 40 | 100 | 230 | 100 | 400 | 230 | 900 | 450 | ||

| 1/15 | 10 | 30 | 40 | 100 | 230 | 100 | 400 | 230 | 900 | 450 | |||

| 1/16 | 15 | 30 | 50 | 150 | 250 | 160 | 500 | 330 | 1200 | 550 | |||

| 1/20 | 15 | 30 | 50 | 150 | 250 | 160 | 500 | 330 | 1200 | 550 | |||

| 1/25 | 15 | 30 | 50 | 150 | 250 | 160 | 500 | 330 | 1200 | 550 | |||

| 1/28 | 15 | 30 | 50 | 150 | 250 | 160 | 500 | 330 | 1100 | 550 | |||

| 1/30 | 10 | 30 | 40 | 100 | 230 | 100 | 450 | 330 | 900 | 450 | |||

| 1/35 | 15 | 30 | 50 | 150 | 250 | 160 | 500 | 330 | 1100 | 550 | |||

| 1/40 | 15 | 30 | 50 | 150 | 250 | 160 | 500 | 330 | 1100 | 550 | |||

| 1/50 | 15 | 30 | 50 | 150 | 250 | 160 | 500 | 330 | 1100 | 550 | |||

| 1/60 | 15 | 30 | 50 | 150 | 250 | 160 | 500 | 330 | 1100 | 550 | |||

| 1/70 | 12 | 30 | 50 | 120 | 250 | 160 | 500 | 290 | 1100 | 550 | |||

| 1/100 | 10 | 30 | 40 | 100 | 230 | 100 | 400 | 230 | 900 | 450 | |||

| Max. Output Torque | Nm | L1,L2 | 3-100 | 3 Times of Normal Output Torque | |||||||||

| Input Speed | Rpm | L1,L2 | 3-100 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 |

| Standard Backlash | Arcmin | L1 | 3-10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 |

| L2 | 12-100 | ≤15 | ≤15 | ≤15 | ≤15 | ≤15 | ≤15 | ≤15 | ≤15 | ≤15 | ≤15 | ||

| Precision Backlash B2 | Arcmin | L1 | 3-10 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 |

| L2 | 12-100 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ||

| PrecisionBacklash B1 | Arcmin | L1 | 3-10 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | |

| L2 | 12-100 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | |||

| Max. Radial Force | N | L1,L2 | 3-100 | 1100 | 3250 | 3250 | 5850 | 9100 | 9100 | 14300 | 14300 | 19500 | 19500 |

| Max. Axial Force | N | L1,L2 | 3-100 | 650 | 3250 | 3250 | 5850 | 9100 | 9100 | 14300 | 14300 | 19500 | 19500 |

| Efficiency | % | L1 | 3-10 | 90% | |||||||||

| L2 | 12-100 | 85% | |||||||||||

| Weight | Kg | L1 | 3-10 | 1.8 | 2.9 | 3.8 | 10.5 | 15.5 | 12.5 | 31 | 25.5 | 56.5 | 37.5 |

| L2 | 12-100 | 2.1 | 3.3 | 4.3 | 11.2 | 17 | 13.2 | 35.5 | 28.5 | 63.5 | 42 | ||

| Operating Temp. | ℃ | L1,L2 | 3-100 | (-10℃~+80℃) | |||||||||

| Lubrication | L1,L2 | 3-100 | COMPLEX HV2 | ||||||||||

| Mounting Position | L1,L2 | 3-100 | Any Direction | ||||||||||

| Noise Level | dB(A) | L1,L2 | 3-100 | ≤68 | ≤68 | ≤68 | ≤68 | ≤70 | ≤70 | ≤72 | ≤72 | ≤74 | ≤74 |

Dimensions

Input sizes

FAQ

1. What’s your delivery time?

Lead time: Normally 15-25 days after confirm your deposit. Products in stock will be delivered 3-5 days after your deposit.

2. What’s your MOQ?

MOQ is 1 PC

3. How long is your warranty?

Warranty: 1 year

4. Planetary gearbox can be customized?

Yes, please send your servo motor dimensions drawing.

5. Where is the gearbox manufactured?

Produced in Taiwan.

6. Your gearbox was ever shipped to which countries?

Our gearbox has been sold to various countries like Russia, Vietnam, Canada, Australia, UAE, Japan etc..

7.You are a factory or trading company?

We are factory, the manufacture