Features

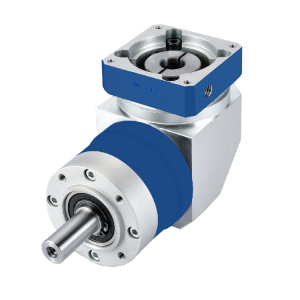

PER series is an economical precision right angle gearbox.This speed reducer is with shaft output and the output side flange is round,makes it easier to match the motion system.The planetary gear on the shaft is supported by both ends of the full needle roller bearing, which enhances the torsion stiffness.This makes PER right angle gearbox bear large torque with high rigidity and low noise, and service for longer time.Both ends of the PER right angle output shaft are supported by high-precision low-clearance bearings to achieve greater bearing capacity.So PER planetary gearboxes are with high torque and suitable for large load transmission occasions.The optimized design of 90 degree saves the mounting space.Besides,as an economical type,PER right angle gearbox is the ideal option for limited budget.

FHTW PER right angle planetary gearbox has the frame size:60mm,80mm,120mm,160mm.

PER precision planetary gearboxes have a broad range of ratio from 3 to 200.It’s input dimensions can be customized depends on the motor output sizes.

Main features of PER right angle planetary gearbox

1.Space-saving

Right angle reducer using spiral bevel gear,customer can locate the motor at 90 degree away from the reducer if required to save space

2.High rigidity&torque

High rigidity&high torque was achieved by uncaged needle roller bearings.

3.Adapter-bushing connection

Can be attached to any motor all over the world.

4.No grease leakage

Perfect solution by high viscosity anti-separation grease.

5.Maintenance-free

No need to replace the grease for the life time.Can be attached in any position.

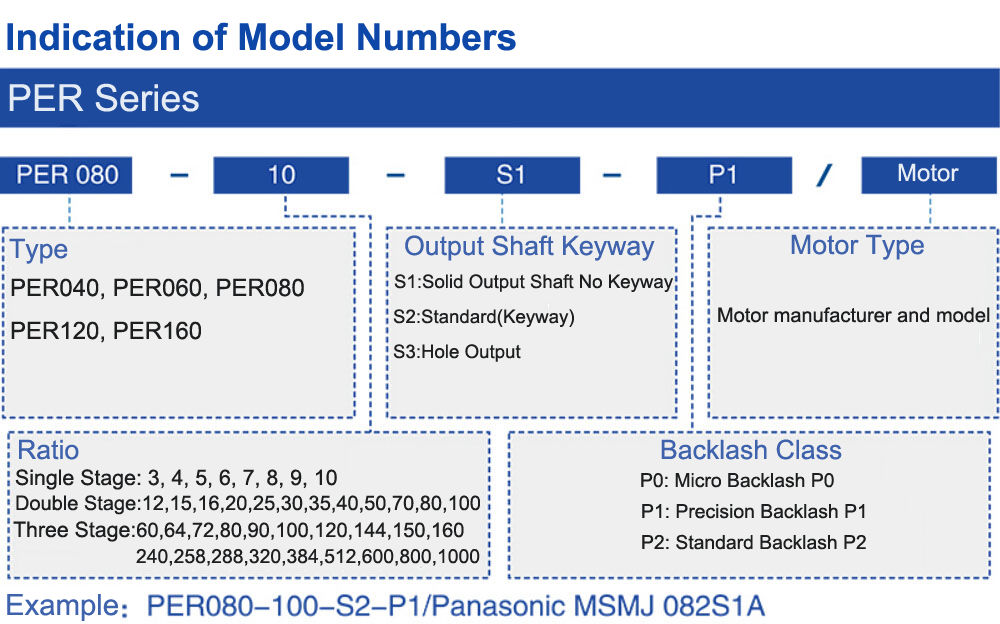

Model Selection

Before choosing a gearbox, please specify the gear ratio you need. After determine a ratio, multiplying your servo motor rated torque by the ratio, the value should be in principle less than our gearbox rated output torque which can be found int the data sheets. Take other overloads which drive the motor into consideration, to choose the max. Operating torque, this should not exceed 2 times of our gearbox rated torque.

After determine the above, you can choose a smallest volume gearbox to save cost.

You can send us the servo motor dimension drawing for model selection or advise the specific servo motor model number.

If you have special requirement for the precision, please clarify.

PER series precision planetary gearbox can connect to any brand of servo motors and stepper motors.

PER single stage reduction ratio:3, 4, 5, 6, 7, 8, 9, 10

PER double stage reduction ratio:12,15,20,25,30,35,40,45,50,60,70,80,90,100

How to choose a correct PER model?

(1)Check your motor drawing,offer the below dimensions:

φS:shaft diameter

LB:motor convex circle diameter

φLA:motor flange PCD

LS:shaft length

LE:motor convex circle thickness

φLZ:motor mounting hole size

Then compare these dimensions to our gearbox dimensions(refer to our catalogue)you can probably know the frame size of our gearbox.

(2)What’s the ratio or output speed you need?Check if the gearbox output torque>motor torque*ratio

Ratio i=Input speed(RPM)/gearbox output speed(RPM)

Motor torque(N.m)=9550*motor power(KW)/motor speed(RPM)

(3)Make sure the precision(backlash)you need,then you can know which type of gearbox you need.

(4)If you don’t have the information above,please send us the servo motor dimension drawing for model selection or advise the specific servo motor model number,then we are pleasure to help you choose a suitable model.

Applications of PER precision right angle gearbox

PER series planetary reducers are widely used in Printer, Belt Conveyer, Gantry Robot, Auto packing sealing machine, Packing machine ( vertical pillow), Packing machine ( horizontal pillow), Dispenser Robot, Loader robot etc.

Parameters

| Model No. | Unit | Stage | Ratio | PER040 | PER060 | PER080 | PER120 | PER160 |

| Rated Output Torque | Nm | 1 | 3 | 17 | 28 | 112 | 165 | 423 |

| 4 | 15 | 38 | 110 | 146 | 364 | |||

| 5 | 14 | 40 | 108 | 160 | 423 | |||

| 7 | 13 | 35 | 105 | 149 | 358 | |||

| 10 | 12 | 25 | 100 | 141 | 293 | |||

| 2 | 15 | 17 | 28 | 112 | 165 | 423 | ||

| 20 | 15 | 38 | 110 | 146 | 364 | |||

| 25 | 14 | 40 | 108 | 160 | 423 | |||

| 30 | 13 | 28 | 112 | 165 | 423 | |||

| 35 | 13 | 35 | 105 | 149 | 358 | |||

| 40 | 12 | 38 | 110 | 146 | 364 | |||

| 50 | 14 | 40 | 108 | 160 | 423 | |||

| 70 | 13 | 35 | 105 | 149 | 358 | |||

| 100 | 12 | 25 | 100 | 141 | 293 | |||

| Max. Output Torque | Nm | 1,2 | 3-100 | 3 Times of Normal Output Torque | ||||

| Rated Input Speed | Rpm | 1,2 | 3-100 | 3000 | 3000 | 3000 | 3000 | 2500 |

| Max. Input Speed | Rpm | 1,2 | 3-100 | 5000 | 5000 | 5000 | 5000 | 3600 |

| Precision Backlash P1 | Arcmin | 1 | 3-10 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 |

| 2 | 12-100 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ||

| Standard Backlash P2 | Arcmin | 1 | 3-10 | ≤11 | ≤11 | ≤11 | ≤11 | ≤11 |

| 2 | 12-100 | ≤13 | ≤13 | ≤13 | ≤13 | ≤13 | ||

| Torsional Rigidity | Nm/arcmin | 1,2 | 3-100 | 3 | 6 | 12 | 22 | 50 |

| Max. Radial Force | N | 1,2 | 3-100 | 320 | 460 | 1300 | 3200 | 6520 |

| Max. Axial Force | N | 1,2 | 3-100 | 160 | 230 | 660 | 1600 | 3260 |

| Service Life | Hr | 1,2 | 3-100 | 20000hrs | ||||

| Efficiency | % | 1 | 3-10 | ≥97% | ||||

| 2 | 15-100 | ≥94% | ||||||

| Weight | Kg | 1 | 3-10 | 0.73 | 0.99 | 2.1 | 4.98 | 18.2 |

| 2 | 15-100 | 1.05 | 1.46 | 3.2 | 6.92 | 24.9 | ||

| Operating Temperature | ℃ | 1,2 | 3-100 | (-25℃~+90℃) | ||||

| Lubrication | 1,2 | 3-100 | Synthetic Grease | |||||

| Protection Class | 1,2 | 3-100 | IP65 | |||||

| Mounting Position | 1,2 | 3-100 | Any Direction | |||||

| Noise Level | dB(A) | 1,2 | 3-100 | ≤62 | ≤63 | ≤65 | ≤67 | ≤68 |

Moment of Inertia

| Model No | Unit | Stage | Ratio | PER040 | PER060 | PER080 | PER120 | PER160 |

| Moment of Inertia | kg.cm2 | 1 | 3 | 0.16 | 0.63 | 3.48 | 12.84 | 36.72 |

| 4 | 0.16 | 0.6 | 3.31 | 12.22 | 34.63 | |||

| 5 | 0.16 | 0.59 | 3.28 | 12.1 | 34.24 | |||

| 7 | 0.16 | 0.59 | 3.27 | 12.05 | 34.07 | |||

| 10 | 0.16 | 0.59 | 3.26 | 12.03 | 34.02 | |||

| 2 | 12-40 | 0.16 | 0.59 | 3.26 | 12.03 | 34.02 | ||

| 50-100 | 0.16 | 0.59 | 3.26 | 12.03 | 34.02 |

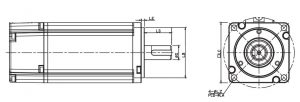

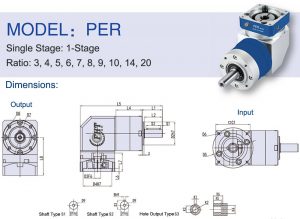

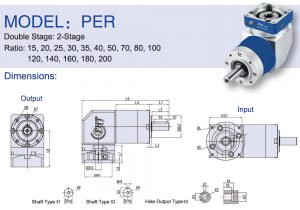

Dimensions

Reducer Dimensions:

(1) Single stage(Ratio:3, 4, 5,6,7,8,9,10,14,20)

Unit:mm

| Size | PER060-L1 | PER080-L1 | PER120-L1 | PER160-L1 |

| D1 | Φ14(16) | Φ20(22) | Φ25(32) | Φ40 |

| D2 | Φ40 | Φ60 | Φ80 | Φ130 |

| D3 | Φ14(6.35-19) | Φ19(11-24) | Φ22(16-24) | Φ35(22-38) |

| D4 | Φ50(30-70) | Φ70(50-110) | Φ110(55.5-110) | Φ114.3(110-114.3) |

| D5 | Φ70(45-90) | Φ90(70-145) | Φ145(90-155) | Φ200(145-200) |

| D6 | 4-M4(M3-M6) | 4-M5(M4-M8) | 4-M8(M6-M12) | 4-M12(M8-M12) |

| D7 | Φ52 | Φ70 | Φ100 | Φ145 |

| D8 | 4-M5X10L | 4-M6X12L | 4-M10X20L | 4-M12X24L |

| D9 | M5X0.8P | M8X1.25P | M10X1.5P | M16X2P |

| L1 | 35 | 40 | 55 | 87 |

| L2 | 31 | 35 | 49 | 80 |

| L3 | 3 | 3 | 4 | 5 |

| L4 | 46 | 55 | 80 | 111 |

| L5 | 143 | 190 | 273 | 295 |

| L6 | 5(4-6) | 8(5-8) | 8(5-8) | 5(5-7) |

| L7 | 32(32-44) | 42(42-60) | 70(59-70) | 86(62-86) |

| L8 | 66(66-88) | 95.5(95.5-113.5) | 130(119-130) | 165.5(165.5-189.5) |

| C1 | 60(60-90) | 90(90-130) | 130(120) | 175(142) |

| S1 | 3 | 3 | 5 | 5 |

| S2 | 25 | 30 | 40 | 70 |

| S3 | 16 | 22.5 | 28 | 43 |

| B | 5 | 6 | 8 | 12 |

| K1 | 4 | 6 | 8 | 12 |

| K2 | Φ11 | Φ22 | Φ28 | Φ38 |

| K3 | 12.8 | 24.5 | 31.3 | 41.3 |

| K4 | Φ16 | Φ32 | Φ38 | Φ48 |

| K5 | 15 | 20 | 27 | 35 |

| K6 | 18 | 24 | 32 | 40 |

Note 1:Inside of ()is the optional range of sizes,outside of ()is the standard sizes.

Note 2:The reducer output shaft size and length can be customized for customers.

Note 3:Input sizes can be subject to changed according to kinds of servo motor or stepper motor size.

(2) Double stage(Ratio: 15,20,25,30,35,40,50,70,80,100,120,140,160,180,200)

unit:mm

| Size | PER060-L2 | PER080-L2 | PER120-L2 | PER160-L2 |

| D1 | Φ14(16) | Φ20(22) | Φ25(32) | Φ40 |

| D2 | Φ40 | Φ60 | Φ80 | Φ130 |

| D3 | Φ14(6.35-19) | Φ19(11-24) | Φ22(16-24) | Φ35(22-38) |

| D4 | Φ50(30-70) | Φ70(50-110) | Φ110(55.5-110) | Φ114.3(110-114.3) |

| D5 | Φ70(45-90) | Φ90(70-145) | Φ145(90-155) | Φ200(145-200) |

| D6 | 4-M4(M3-M6) | 4-M5(M4-M8) | 4-M8(M6-M12) | 4-M12(M8-M12) |

| D7 | Φ52 | Φ70 | Φ100 | Φ145 |

| D8 | 4-M5X10L | 4-M6X12L | 4-M10X20L | 4-M12X24L |

| D9 | M5X0.8P | M8X1.25P | M10X1.5P | M16X2P |

| L1 | 35 | 40 | 55 | 87 |

| L2 | 31 | 35 | 49 | 80 |

| L3 | 3 | 3 | 4 | 5 |

| L4 | 62 | 78.5 | 110 | 149 |

| L5 | 143 | 190 | 273 | 295 |

| L6 | 5(4-6) | 8(5-8) | 8(5-8) | 5(5-7) |

| L7 | 32(32-44) | 42(42-60) | 70(59-70) | 86(62-86) |

| L8 | 66(66-88) | 95.5(95.5-113.5) | 130(119-130) | 165.5(165.5-189.5) |

| C1 | 60(60-90) | 90(90-130) | 130(120) | 175(142) |

| S1 | 3 | 3 | 5 | 5 |

| S2 | 25 | 30 | 40 | 70 |

| S3 | 16 | 22.5 | 28 | 43 |

| B | 5 | 6 | 8 | 12 |

| K1 | 4 | 6 | 8 | 10 |

| K2 | Φ11 | Φ22 | Φ28 | Φ38 |

| K3 | 12.8 | 24.5 | 31.3 | 41.3 |

| K4 | Φ16 | Φ32 | Φ38 | Φ48 |

| K5 | 15 | 20 | 27 | 35 |

| K6 | 18 | 24 | 32 | 40 |

Note 1:Inside of ()is the optional range of sizes,outside of ()is the standard sizes.

Note 2:The reducer output shaft size and length can be customized for customers.

Note 3:Input sizes can be subject to changed according to kinds of servo motor or stepper motor size.

Download

Real Pictures

FAQ

1. What’s your delivery time?

Lead time: Normally 10-15 days after confirm your deposit. Products in stock will be delivered 3-5 days after your deposit.

2. What’s your MOQ?

MOQ is 1 PC

3. How long is your warranty?

Warranty: 1 year

4. Planetary gearbox can be customized?

Yes, please send your motor dimensions drawing.

5. Where is the gearbox manufactured?

Produced in Taiwan.

6. Your gearbox was ever shipped to which countries?

Our gearbox has been sold to all over the world

7. You are a factory or trading company?

We are factory, the manufacturer.