Features

SWL series screw lift is a basic lifting device, with multiply functions of raising, failing and pushing by means of auxiliary parts, turn over, various height adjustment. SWL screw lift are suitable for low speed, low frequency occasions, the main components are : precise trapezoid screw pairs and high precise worm gear pairs.

If the screw lift suffer from larger vibration and impact load, the self-locking may run out of order, so please add the brake unit.

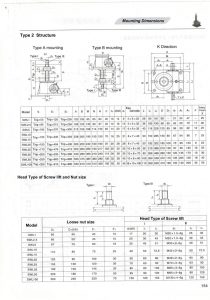

There are two structure and mounting types:

Type 1: Screw rod make axial movement ( When screw rod move, it will be divided into rotation and non-rotation), please pay attention to this when select models.

Type 2: Screw rod make rotating movement, nut make axial movement.

Mounting type A: Screw rod or nut move upward

Mounting type B: Screw rod or nut move downward

1.Compact structure, small volume, light weight

2.Extensive power source, no noise, convenient installation

3.Low speed, low frequency: Mainly used in occasions of heavy load, low speed, no frequent working.

4.Keep loading: The trapezoid screw rod has function of self locking, it can keep loading without brake.

5.Flexible applications, multiple functions, multiple match models, high reliability, long service time.

6.Can be used separately and used in a combination

7.The screw lift can accurately control and adjust the height of raising and pushing according to a certain procedure.

8.Can be driven directly by motor or other power, also manual is okay.

9.Own different structures and assemble types, the raising height can be customized as per customers’ requirements.

Parameters

| Model | SWL1 | SWL2.5 | SWL5 | SWL10 | SWL15 | SW20 | SW25 | SW35 | SW50 | |

| Max. Lift Force (KN) | 10 | 25 | 50 | 100 | 150 | 200 | 250 | 350 | 500 | |

| Screw Rod Thread Size | Tr22x4 | Tr30x6 | Tr40x7 | Tr58x12 | Tr65x12 | Tr90x16 | Tr100x20 | Tr120x20 | ||

| Max. Tensile Force (KN) | 10 | 25 | 50 | 99 | 166 | 250 | 350 | 500 | ||

| Worm Gear ratio | P | 1/6 | 1/6 | 1/8 | 3/32 | 1/8 | 3/32 | 3/32 | 1/11 | |

| M | 1/24 | 1/24 | 1/24 | 1/24 | 1/24 | 1/32 | 1/32 | 1/32 | ||

| Screw Rod Stroke/R (mm) | P | 0.8 | 1 | 0.875 | 1.565 | 1.56 | 1.5 | 1.875 | 1.818 | |

| M | 0.21 | 0.25 | 0.292 | 0.5 | 0.5 | 0.5 | 0.625 | 0.625 | ||

| Max. elogation of screw rod under tension load (mm) | 1300 | 1500 | 2000 | 2500 | 3000 | 3500 | 4000 | 5500 | ||

| Max. Lift height under max. pressure load (mm) | Screw head with guiding | 220 | 250 | 385 | 500 | 400 | 490 | 850 | 820 | 900 |

| Screw head without guiding | 300 | 400 | 770 | 1000 | 800 | 980 | 1700 | 1640 | 1900 | |

| Worm torque with full load (N.m) | P | 15 | 18 | 39.5 | 119 | 179 | 240 | 3660 | 464 | 650 |

| M | 8.3 | 8.86 | 19.8 | 60 | 90 | 122 | 217 | 253 | 350 | |

| Efficiency (%) | P | 20 | 22 | 23 | 20.5 | 19.5 | 16 | 18 | 20 | |

| M | 9 | 11 | 11.5 | 13 | 12.8 | 9 | 11 | 15 | ||

| Power (KW) | 0.25 | 0.55 | 1.5 | 2.6 | 3.7 | 4.8 | 6 | 7.5 | ||

| Weight without stroke (Kg) | 6.3 | 7.3 | 16.2 | 25 | 36 | 70.5 | 87 | 95 | ||

| Screw weight per 100mm (Kg) | 0.35 | 0.45 | 0.82 | 1.67 | 2.15 | 4.15 | 5.2 | 6.35 | ||

| Lubricant | Synthetic Calcium-sodium base grease ZGN-1 or ZGN-2 (-20℃~+100℃) | |||||||||

| Grease Weight (Kg) | 0.08 | 0.1 | 0.3 | 0.5 | 0.75 | 1.1 | 1.9 | 2.2 | ||

Application

Platform lifting, working height adjustment of surface processing machine, tilt level adjusting of sliding transmission belt, working height modification of corrector, automatic opening and closing of large scale windows and doors.

Installation

1.When the pressure load reduce, the rising height will increase.

2.When increase the different loads, the allowable torque, power,speed are also different, and the max.powers at different working continuous rate are different.

3.Screw lift with structure of screw motion with oil grease lubricated, please add the lubrication timely with the rising of temperature.

4.The efficiency in the parameter sheet are the values for the screw lift which use grease lubrication.

5.The lubrication should be changed timely during working time.

6.Working temperature:-20 degree to +80 degree

7.Generally the screw lift can be self-locking under static condition.

FAQ

1. What’s your delivery time?

Lead time: Normally 15-25 days after confirm your deposit. Products in stock will be delivered 3-5 days after your deposit.

2. What’s your MOQ?

MOQ is 1 PC

3. How long is your warranty?

Warranty: 1 year

4. Screw lift can be customized?

Yes, please send your technical requirement for our confirmation.

5. Where is the screw lift manufactured?

Produced in China mainland..

6. Your screw lift was ever shipped to which countries?

Our gearbox has been sold to various countries like Russia, Vietnam, Canada, Australia, UAE, Japan etc..

7.You are a factory or trading company?

We are factory, the manufacturer.