Features

AT-FL1/AT-FR1 spiral bevel gearbox is with one solid output shaft on left or right. The input side is with motor adapter for easy installation without any connection accessories.

The right angle bevel gearbox has steel housing, silver oxidized, aluminum blue anodized motor adapter plate,featuring a compact structure.The optimized design makes the right angle gearbox with a low noise rotation.

Steel output shaft of AT-FL1/AT-FR1 right angle gearbox can be with or without key according to practical application.

The right angle gearbox consists of spiral bevel gears, planetary part with spur gears,so it is also called right angle spiral bevel gearbox,right angle planetary gearbox or 90 degree gearbox.

AT-FL1/AT-FR1 right angle spiral bevel gearbox has a broad range of nominal torques 12 Nm - 3.200 Nm,applied to different kinds of rotation load.

The right angle spiral bevel gearbox has a extensive range of reduction ratios:

1-stage : 1 / 1,5 / 2 / 3 / 4 / 5

2-stage : 7 / 10 / 15 / 20 / 25 / 35 / 50

3-stage : 75 / 100 / 125 / 150 / 200 / 250 / 350 / 500

The 90 degree servo gearbox is with low backlash,suitable for high precision drive system:

1-stage : ≤ 6 arcmin

2-stage : ≤ 8 arcmin

3-stage : ≤ 10 arcmin

AT-FL1/AT-FR1 is a high efficiency right angle gearbox:

1-stage : ≥ 98%

2-stage : ≥ 94%

3-stage : ≥ 94%

AT-FL1/AT-FR1 bevel gearbox has a vast range of sizes:

ATB065FL1 / AT0B75FL1 / ATB090FL1 / ATB110FL1 / ATB140FL1 / ATB170FL1 / ATB210FL1 / ATB240FL1 / ATB280FL1

ATB065FR1 / ATB075FR1 / ATB090FR1 / ATB110FR1 / ATB140FR1 / ATB170FR1 / ATB210FR1 / ATB240FR1 / ATB280FR1

Application

Widel used in printing-Converting,Packaging,Test Stands,Wire-Cable,General Purpose,Tension Control,Registration Control,Right Angle Drives,Intermediate Tension Control,Pre-stretch Tension Control,Speed and Torque Distribution,Precise Simulation of Variable Torque,Speed Increaser,Ring Gear & Pinion Drives -Very High Performances,Tension Control Wire Cable,Main Speed Adjustment,Pulling Caterpillar,Differential Speed Adjustment,Right Angle Bevel Gearboxes,Machine Tools, Belt Conveyors, Gantry Robot, Auto packing sealing machine,Dispenser Robot, Loader robot and some other heavy load case.

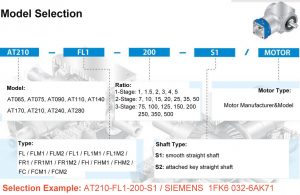

Model indication

Parameters

| Specification | Stages | Ratio | AT065 FL1 AT065 FR1 | AT075 FL1 AT075 FR1 | AT090 FL1 AT090 FR1 | AT110 FL1 AT110 FR1 | AT140 FL1 AT140 FR1 | AT170 FL1 AT170 FR1 | AT210 FL1 AT210 FR1 | AT240 FL1 AT240 FR1 | AT280 FL1 AT280 FR1 | |

| Rated output torque | Nm | 1 | 1 | 25 | 45 | 78 | 150 | 360 | 585 | 1300 | 2150 | 3200 |

| 1.5 | 25 | 45 | 78 | 150 | 360 | 585 | 1300 | 2150 | 3200 | |||

| 2 | 24 | 42 | 68 | 150 | 330 | 544 | 1220 | 2010 | 3050 | |||

| 3 | 18 | 33 | 54 | 120 | 270 | 450 | 1020 | 1650 | 2850 | |||

| 4 | 13 | 28 | 48 | 100 | 224 | 376 | 860 | 1410 | 2300 | |||

| 5 | 12 | 25 | 40 | 85 | 196 | 320 | 740 | 1210 | 2000 | |||

| 2 | 7 | 12 | 12 | 33 | 91 | 91 | 91 | 195 | 358 | 358 | ||

| 10 | 24 | 28 | 68 | 150 | 208 | 208 | 430 | 846 | 846 | |||

| 15 | 18 | 33 | 54 | 120 | 270 | 312 | 645 | 1269 | 1269 | |||

| 20 | 13 | 28 | 48 | 100 | 224 | 376 | 860 | 1410 | 1692 | |||

| 25 | 12 | 25 | 40 | 85 | 196 | 320 | 740 | 1210 | 2000 | |||

| 35 | 12 | 25 | 40 | 85 | 196 | 320 | 740 | 1210 | 1790 | |||

| 50 | 12 | 25 | 40 | 85 | 196 | 320 | 740 | 1210 | 1465 | |||

| 3 | 75 | * | * | * | 120 | 210 | 312 | 585 | 1269 | 1269 | ||

| 100 | * | * | * | 100 | 224 | 376 | 780 | 1410 | 1692 | |||

| 125 | * | * | * | 85 | 196 | 320 | 740 | 1210 | 2000 | |||

| 150 | * | * | * | 120 | 135 | 312 | 390 | 975 | 975 | |||

| 200 | * | * | * | 100 | 180 | 376 | 520 | 1300 | 1300 | |||

| 250 | * | * | * | 85 | 196 | 320 | 650 | 1210 | 1625 | |||

| 350 | * | * | * | 85 | 196 | 320 | 740 | 1210 | 1790 | |||

| 500 | * | * | * | 85 | 196 | 320 | 740 | 1210 | 1465 | |||

| Max.output torque | Nm | 1,2,3 | 1~500 | 1.5 Times of Rated Output Torque | ||||||||

| Max.input speed | rpm | 1 | 1~5 | 7500 | 6500 | 5500 | 4500 | 3500 | 3000 | 2200 | 2000 | 1700 |

| 2 | 7~50 | 8000 | 8000 | 6000 | 6000 | 6000 | 6000 | 4800 | 3600 | 3600 | ||

| 3 | 75~500 | * | * | * | 8000 | 8000 | 6000 | 6000 | 6000 | 6000 | ||

| Backlash | arcmin | 1 | 1~5 | ≤6 | ≤6 | ≤6 | ≤6 | ≤6 | ≤6 | ≤6 | ≤6 | ≤6 |

| 2 | 7~50 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ||

| 3 | 75~500 | * | * | * | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ||

| Radial force Output shaft d2 | N | 1,2,3 | 1~500 | 900 | 1100 | 1700 | 2700 | 4800 | 6600 | 11500 | 16000 | 18000 |

| Axial force Output shaft d2 | N | 1,2,3 | 1~500 | 450 | 550 | 850 | 1350 | 2400 | 3300 | 5750 | 8500 | 9000 |

| Service life | hr | 1,2,3 | 1~500 | 20000 | ||||||||

| Efficiency | % | 1 | 1~5 | ≥98% | ||||||||

| 2,3 | 7~500 | ≥94% | ||||||||||

| Operation Temp | ℃ | 1,2,3 | 1~500 | minus10℃~90℃ | ||||||||

| Lubrication | Synthetic Grease | |||||||||||

| Noise level | dB(A) | 1,2,3 | 1~500 | ≤71 | ≤72 | ≤76 | ≤77 | ≤78 | ≤79 | ≤81 | ≤83 | ≤84 |

Moment of inertia

| Specification | Stages | Ratio | AT065 FL1 AT065 FR1 | AT075 FL1 AT075 FR1 | AT090 FL1 AT090 FR1 | AT110 FL1 AT110 FR1 | AT140 FL1 AT140 FR1 | AT170 FL1 AT170 FR1 | AT210 FL1 AT210 FR1 | AT240 FL1 AT240 FR1 | AT280 FL1 AT280 FR1 | |

| Moment of inertia | kg.cm2 | 1 | 1 | 0.51 | 1.3 | 3.14 | 7.62 | 23.54 | 59.09 | 195.96 | 365.38 | 787.63 |

| 1.5 | 0.46 | 1.15 | 2.8 | 6.65 | 19.34 | 49.38 | 156.02 | 279.62 | 584.28 | |||

| 2 | 0.44 | 1.1 | 2.68 | 6.23 | 17.72 | 45.44 | 140.8 | 245.78 | 500.26 | |||

| 3 | 0.43 | 1.09 | 2.64 | 6.08 | 17.16 | 44.11 | 135.51 | 233.75 | 471.56 | |||

| 4 | 0.43 | 1.08 | 2.63 | 6.05 | 17.03 | 43.79 | 134.14 | 230.77 | 464.76 | |||

| 5 | 0.43 | 1.08 | 2.63 | 6.04 | 16.99 | 43.69 | 133.71 | 229.71 | 462.08 | |||

| 2 | 7 | 0.15 | 0.15 | 0.5 | 2.79 | 2.79 | 2.79 | 9.91 | 29.26 | 29.26 | ||

| 10 | 0.15 | 0.15 | 0.5 | 2.8 | 2.8 | 2.8 | 9.96 | 29.43 | 29.43 | |||

| 15 | 0.15 | 0.15 | 0.5 | 2.8 | 2.8 | 2.8 | 9.96 | 29.43 | 29.43 | |||

| 20 | 0.15 | 0.15 | 0.5 | 2.8 | 2.8 | 2.8 | 9.96 | 29.43 | 29.43 | |||

| 25 | 0.15 | 0.15 | 0.5 | 2.8 | 2.8 | 2.8 | 9.96 | 29.43 | 29.43 | |||

| 35 | 0.15 | 0.15 | 0.5 | 2.79 | 2.79 | 2.79 | 9.91 | 29.26 | 29.26 | |||

| 50 | 0.15 | 0.15 | 0.5 | 2.79 | 2.79 | 2.79 | 9.89 | 29.2 | 29.2 | |||

| 3 | 75 | * | * | * | 2.8 | 2.8 | 2.8 | 9.96 | 29.43 | 29.43 | ||

| 100 | * | * | * | 2.8 | 2.8 | 2.8 | 9.96 | 29.43 | 29.43 | |||

| 125 | * | * | * | 2.8 | 2.8 | 2.8 | 9.96 | 29.43 | 29.43 | |||

| 150 | * | * | * | 2.79 | 2.79 | 2.79 | 9.89 | 29.2 | 29.2 | |||

| 200 | * | * | * | 2.79 | 2.79 | 2.79 | 9.89 | 29.2 | 29.2 | |||

| 250 | * | * | * | 2.79 | 2.79 | 2.79 | 9.89 | 29.2 | 29.2 | |||

| 350 | * | * | * | 2.79 | 2.79 | 2.79 | 9.89 | 29.2 | 29.2 | |||

| 500 | * | * | * | 2.79 | 2.79 | 2.79 | 9.89 | 29.2 | 29.2 | |||

Weight

| Model | Stage | Ratio | AT065 | AT075 | AT090 | AT110 | AT140 | AT170 | AT210 | AT240 | AT280 | |

| FL series | kg | 1 | 1~5 | 2.8 | 4.4 | 7.1 | 12.1 | 20.9 | 36.1 | 69.4 | 101.2 | 158.3 |

| 2 | 7~50 | 3.2 | 4.8 | 8.1 | 14.3 | 24.2 | 38.5 | 74.1 | 112.4 | 171 | ||

| 3 | 75~500 | * | * | * | 13.9 | 23.7 | 38.8 | 73.4 | 110.2 | 168.7 | ||

| FL1 series | 1 | 1~5 | 2.7 | 4.3 | 7.1 | 11.9 | 20.3 | 35.5 | 68.3 | 99.6 | 156 | |

| 2 | 7~50 | 3.2 | 4.8 | 8 | 14.2 | 23.9 | 37.9 | 73 | 110.8 | 168.6 | ||

| 3 | 75~500 | * | * | * | 13.8 | 23.4 | 38.2 | 72.3 | 108.6 | 166.4 | ||

| FH series | 1 | 1~5 | 2.6 | 4.1 | 6.7 | 11.4 | 18.9 | 32.9 | 63.2 | 92.5 | 146 | |

| 2 | 7~50 | 3.1 | 4.6 | 7.7 | 13.6 | 22.4 | 35.3 | 67.9 | 103.7 | 158.7 | ||

| 3 | 75~500 | * | * | * | 13.3 | 21.9 | 35.6 | 67.2 | 101.5 | 156.5 | ||

| FC series | 1 | 1~5 | 2.9 | 4.4 | 7.2 | 11.8 | 20.4 | 35 | 66.5 | 96 | 151.7 | |

| 2 | 7~50 | 3.3 | 4.9 | 8.2 | 14.1 | 24.1 | 37.4 | 71.2 | 107.2 | 164.4 | ||

| 3 | 75~500 | * | * | * | 13.7 | 23.5 | 37.5 | 70.5 | 105 | 162.2 | ||

| FR1 series | 1 | 1~5 | 2.7 | 4.3 | 7.1 | 11.9 | 20.3 | 35.5 | 68.3 | 99.6 | 156 | |

| 2 | 7~50 | 3.2 | 4.8 | 8 | 14.2 | 23.9 | 37.9 | 73 | 110.8 | 168.6 | ||

| 3 | 75~500 | * | * | * | 13.8 | 23.4 | 38.2 | 72.3 | 108.6 | 166.4 | ||

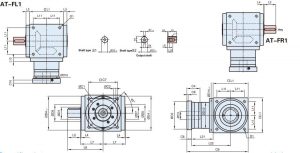

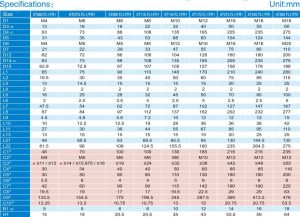

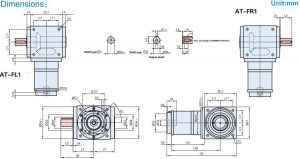

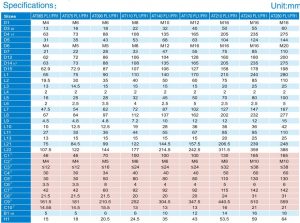

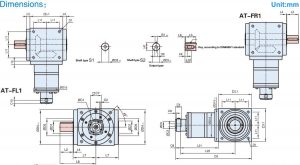

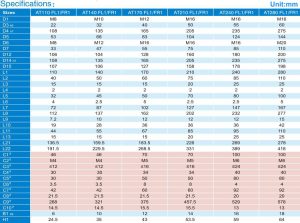

Dimensions