Features

PT-C-K is the single hollow output shaft steering gearbox with keyway.The right angle 90 degree gearbox is suitable for the application that require axis to go through the hollow shaft.

PT-C-K right angle gearbox is with input shaft.The integrated stainless steel body and optimized design ensures PT-C-K right angle gearbox with high precision,high torque and high rigidity ,therefore,rotating smoothly with low noise and generate low heat.

The compact structure feature the right angle steering gearbox a small volume,space-saving and easy installation.The steering gearbox has six frame sizes: PT070A, PT085A, PT105A, PT125B, PT150B, PT180B. Ratio is 1:1 and the rated output torque is 30Nm~600Nm.

PT-C-K steering gearbox is widely used in Printing ,Converting,Packaging,Test Stands,Wire – Cable,General Purpose,Tension Control,Registration Control,Right Angle Drives,Intermediate Tension Control,Pre-stretch Tension Control,Speed and Torque Distribution,Precise Simulation of Variable Torque,Speed Increaser,Ring Gear & Pinion Drives – Very High Performances,Tension Control Wire Cable,Main Speed Adjustment,Pulling Caterpillar,Differential Speed Adjustment,Right Angle Bevel Gearboxes,Machine Tools,etc.

PT-C-K steering gearbox is widely used in Printer, Belt Conveyors, Gantry Robot, Auto packing sealing machine, Packing machine (vertical pillow), Packing machine (horizontal pillow), Dispenser Robot, Loader robot and some other heavy load case.

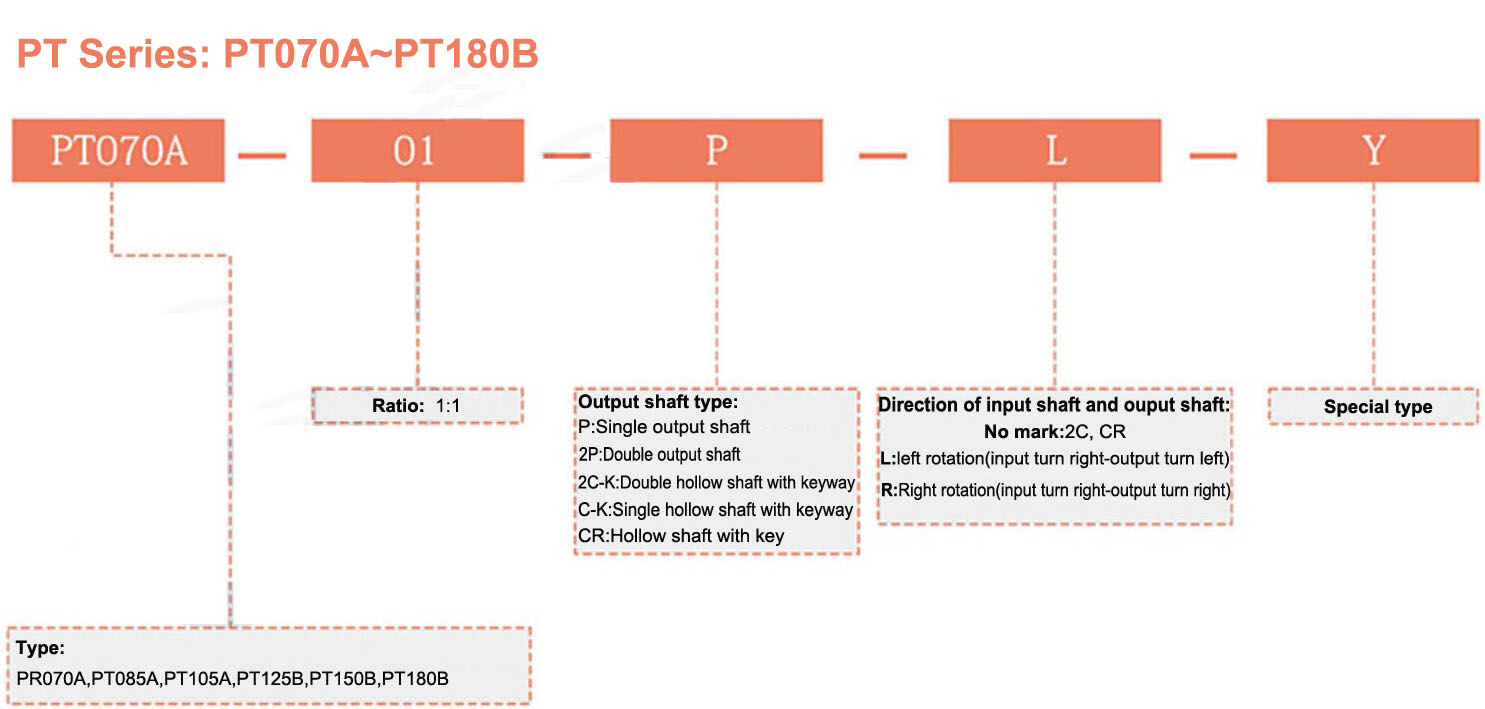

Model indication

Parameters

| Model No. | Unit | Stage | Ratio(i) | PT070A | PT085A | PT105A | PT125B | PT150B | PT180B |

| Rated Output Torque | Nm | L1 | 1/1 | 30 | 40 | 100 | 230 | 400 | 600 |

| 1/3 | 30 | 40 | 100 | 230 | 400 | 450 | |||

| 1/4 | 30 | 50 | 150 | 250 | 500 | 550 | |||

| 1/5 | 30 | 50 | 150 | 250 | 500 | 550 | |||

| 1/6 | 30 | 42 | 120 | 230 | 500 | 530 | |||

| 1/7 | 30 | 42 | 120 | 230 | 500 | 530 | |||

| 1/10 | 30 | 40 | 100 | 230 | 400 | 450 | |||

| L2 | 1/12 | 30 | 40 | 100 | 230 | 400 | 450 | ||

| 1/15 | 30 | 40 | 100 | 230 | 400 | 450 | |||

| 1/16 | 30 | 50 | 150 | 250 | 500 | 550 | |||

| 1/20 | 30 | 50 | 150 | 250 | 500 | 550 | |||

| 1/25 | 30 | 50 | 150 | 250 | 500 | 550 | |||

| 1/28 | 30 | 50 | 150 | 250 | 500 | 550 | |||

| 1/30 | 30 | 40 | 100 | 230 | 450 | 450 | |||

| 1/35 | 30 | 50 | 150 | 250 | 500 | 550 | |||

| 1/40 | 30 | 50 | 150 | 250 | 500 | 550 | |||

| 1/50 | 30 | 50 | 150 | 250 | 500 | 550 | |||

| 1/60 | 30 | 50 | 150 | 250 | 500 | 550 | |||

| 1/70 | 30 | 50 | 120 | 250 | 500 | 550 | |||

| 1/100 | 30 | 40 | 100 | 230 | 400 | 450 | |||

| Max. Output Torque | Nm | L1,L2 | 3-100 | 3 Times of Nominal Output Torque | |||||

| Input Speed | Rpm | L1,L2 | 3-100 | 3000 | 3000 | 3000 | 3000 | 3000 | 3000 |

| Standard Backlash | Arcmin | L1 | 3-10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 | ≤10 |

| L2 | 12-100 | ≤15 | ≤15 | ≤15 | ≤15 | ≤15 | ≤15 | ||

| Precision Backlash B2 | Arcmin | L1 | 3-10 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 |

| L2 | 12-100 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ≤8 | ||

| Precision Backlash B1 | Arcmin | L1 | 3-10 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 | ≤3 |

| L2 | 12-100 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ≤5 | ||

| Max. Radial Force | N | L1,L2 | 3-100 | 3250 | 3250 | 5850 | 9100 | 14300 | 19500 |

| Max. Axial Force | N | L1,L2 | 3-100 | 3250 | 3250 | 5850 | 9100 | 14300 | 19500 |

| Efficiency | % | L1 | 3-10 | 90% | |||||

| L2 | 12-100 | 85% | |||||||

| Weight | Kg | L1 | 3-10 | 2.9 | 3.8 | 10.5 | 15.5 | 31 | 37.5 |

| L2 | 12-100 | 3.3 | 4.3 | 11.2 | 17 | 35.5 | 42 | ||

| Operating Temperature | ℃ | L1,L2 | 3-100 | -10~80℃ | |||||

| Lubrication | L1,L2 | 3-100 | Synthetic Grease | ||||||

| Mounting Position | L1,L2 | 3-100 | Any direction | ||||||

| Noise Level | dB(A) | L1,L2 | 3-100 | ≤68 | ≤68 | ≤68 | ≤70 | ≤72 | ≤74 |

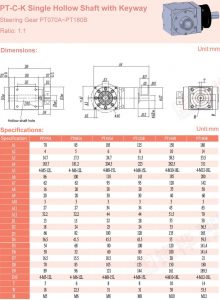

Dimensions